Aluminum alloy compound inoculant and preparation method thereof

A composite inoculant and composite inoculation technology, applied in the field of aluminum alloy inoculants, can solve problems such as restricting the application and promotion of Sc-containing aluminum alloys, high prices, and increased alloy costs, so as to avoid coarsening and segregation, low cost, The effect of small burn loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] According to the chemical composition range of the inoculant of the present invention, the required compound inoculant is processed and prepared, and the preparation process is as follows:

[0027] According to the designed chemical composition ratio: La 0%, Zr 0%, Ti10%, Al90%, weigh the domestic raw materials Al-20La, Al-10Zr and Al-10Ti master alloy for batching. Put all the prepared ingredients into a vacuum high-frequency electromagnetic oscillating electric arc furnace, and pump the vacuum degree in the furnace to 6×10 -2 Pa~8×10 -3 Pa, then pass 0.05MPa high-purity argon into the smelting vacuum chamber, and then set the furnace temperature to a predetermined temperature until the ingredients are all melted, and then keep the temperature for 5 minutes under electromagnetic vibration. When the melt is kept warm for the specified time, it is poured into a quartz mold in a liquid nitrogen cooling environment to prepare a master alloy composite inoculant.

Embodiment 2

[0029] According to the chemical composition range of the inoculant of the present invention, the required compound inoculant is processed and prepared, and the preparation process is as follows:

[0030] According to the designed chemical composition ratio: La 0%, Zr 5%, Ti 5%, Al90%, weigh the domestic raw materials Al-20La, Al-10Zr and Al-10Ti master alloy for batching. Put all the prepared ingredients into a vacuum high-frequency electromagnetic oscillating electric arc furnace, and pump the vacuum degree in the furnace to 6×10 -2 Pa~8×10 -3 Pa, then pass 0.05MPa high-purity argon gas into the smelting vacuum chamber, and then set the furnace temperature to a predetermined temperature until the ingredients are all melted, and then keep it for 5 minutes under electromagnetic vibration. When the melt is kept warm for the specified time, it is poured into a quartz mold in a liquid nitrogen cooling environment to prepare a master alloy composite inoculant.

Embodiment 3

[0032] According to the chemical composition range of the inoculant of the present invention, the required compound inoculant is processed and prepared, and the preparation process is as follows:

[0033] According to the designed chemical composition ratio: La 5%, Zr 5%, Ti 5%, Al 85%, weigh the domestic raw materials Al-20La, Al-10Zr and Al-10Ti master alloy for batching. Put all the prepared ingredients into a vacuum high-frequency electromagnetic oscillating electric arc furnace, and pump the vacuum degree in the furnace to 6×10 -2 Pa~8×10 -3 Pa, then pass 0.05MPa high-purity argon into the smelting vacuum chamber, and then set the furnace temperature to a predetermined temperature until the ingredients are all melted, and then keep it for 5 minutes under electromagnetic vibration. When the melt is kept warm for the specified time, it is poured into a quartz mold in a liquid nitrogen cooling environment to prepare a master alloy composite inoculant.

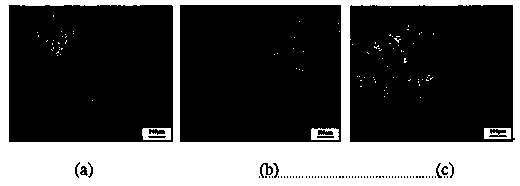

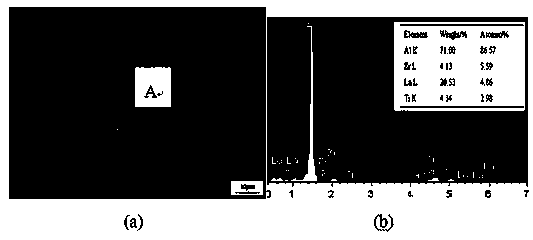

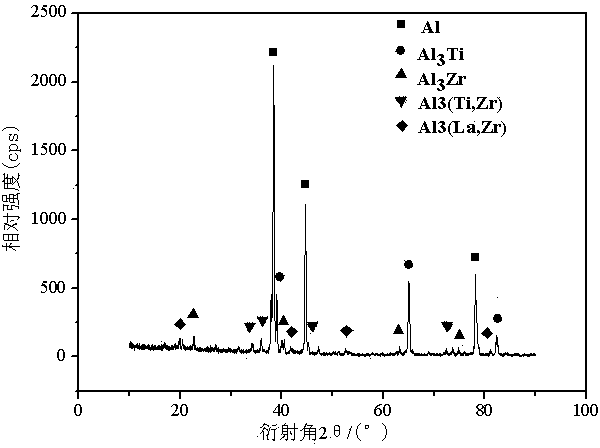

[0034] The Al-La-Zr-Ti com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com