Four color separation printing dye-based ink formula, preparation and application method thereof

A dye ink and application method technology, applied in the field of printing dyes, can solve the problems of large-scale production of four-color printing, difficulty in color imitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

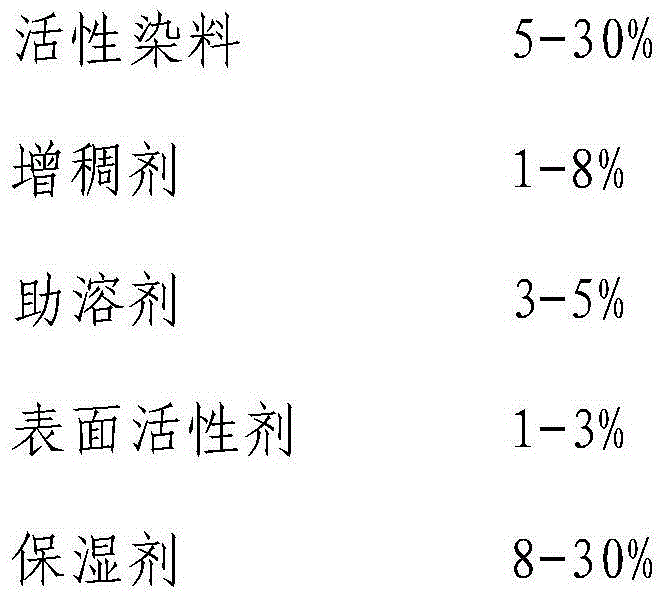

[0034] Based on the four-color printing dye ink of phosphonic acid active group, the content of each component is as follows by weight percentage:

[0035]

[0036] Among them, the reactive dye adopts CMYK color separation mode, which is reactive yellow PT-2R, or reactive red PT-6b, or reactive blue PT-GL, or reactive black PT-N;

[0037] Cosolvent is N,N-dimethylformamide;

[0038] Surfactant is nonionic surfactant, selects alkylphenol polyoxyethylene ether for use;

[0040] The bactericide is a commercially available product;

[0041] The pH buffering agent is sodium dihydrogen phosphate-sodium hydroxide buffer solution; pH=7.5-8.5.

specific Embodiment 2

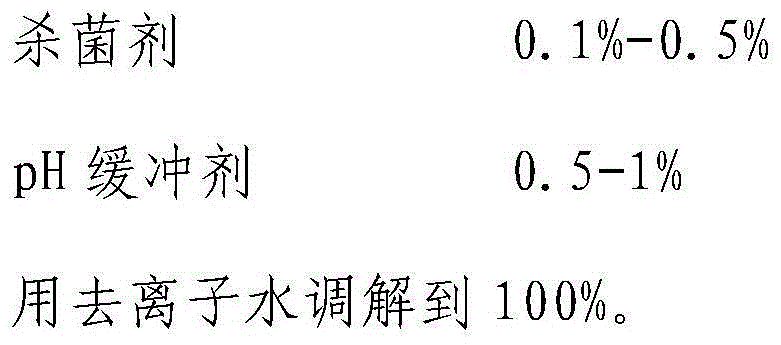

[0042] Based on the four-color printing dye ink of nicotinic acid active group, the content of each component is as follows by weight percentage:

[0043]

[0044] Among them, the reactive dye adopts CMYK color separation mode, which is reactive yellow NF-4G, or reactive red NF-3B, or reactive blue NF-BN, or living navy blue NF-BG;

[0045] The thickener is propylene glycol alginate;

[0046] Cosolvent is ethanol;

[0047] Surfactant is nonionic surfactant, selects fatty alcohol polyoxyethylene ether for use;

[0048] The humectant is ethylene glycol; the bactericide is a commercially available product;

[0049] The pH buffering agent is sodium dihydrogen phosphate-sodium hydroxide buffer solution; pH=7.5-8.5.

specific Embodiment 3

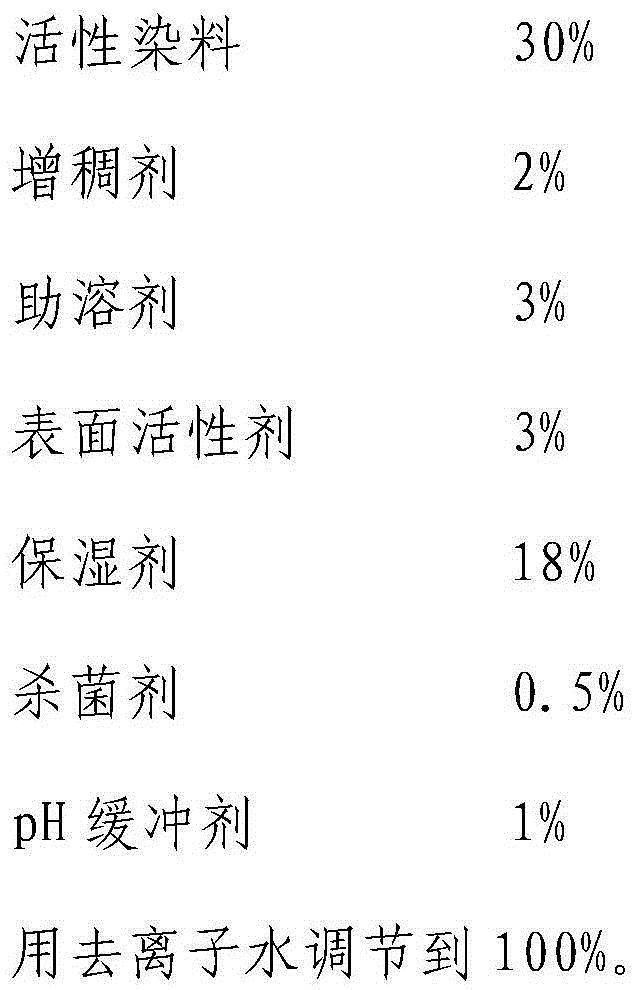

[0050] The four-color printing dye ink based on monochloro-s-triazine and vinyl sulfone type dual active radicals, the content of each component by weight percentage is as follows:

[0051]

[0052] Among them, the reactive dye adopts CMYK color separation mode, which is reactive yellow BF-4R, or reactive red BF-RF, or reactive blue BF-RR, or reactive black B;

[0053] The thickener is propylene glycol alginate;

[0054] Cosolvent is dimethyl sulfoxide;

[0055] Described surfactant is nonionic surfactant, selects fatty alcohol polyoxyethylene ether, or its composition;

[0056] The humectant is glycerol, or a combination thereof;

[0057] The bactericide is a commercially available product;

[0058] The pH buffering agent is sodium dihydrogen phosphate-sodium hydroxide buffer solution; pH=7.5-8.5.

[0059] The preparation method of the four-separation printing dye ink described in specific embodiment one to three may further comprise the steps:

[0060] Step 1, reactive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com