Light emitting device

A light-emitting device and technology for emitting red light, applied in the fields of lighting technology, display and optoelectronics, can solve the problems of harsh preparation method, high price, low brightness, etc., and achieve the effects of low cost, improved light-emitting brightness and novel structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Ca 0.8 Li 0.1 MoO 4-x f x : Eu 0.1 Preparation of fluorescent materials

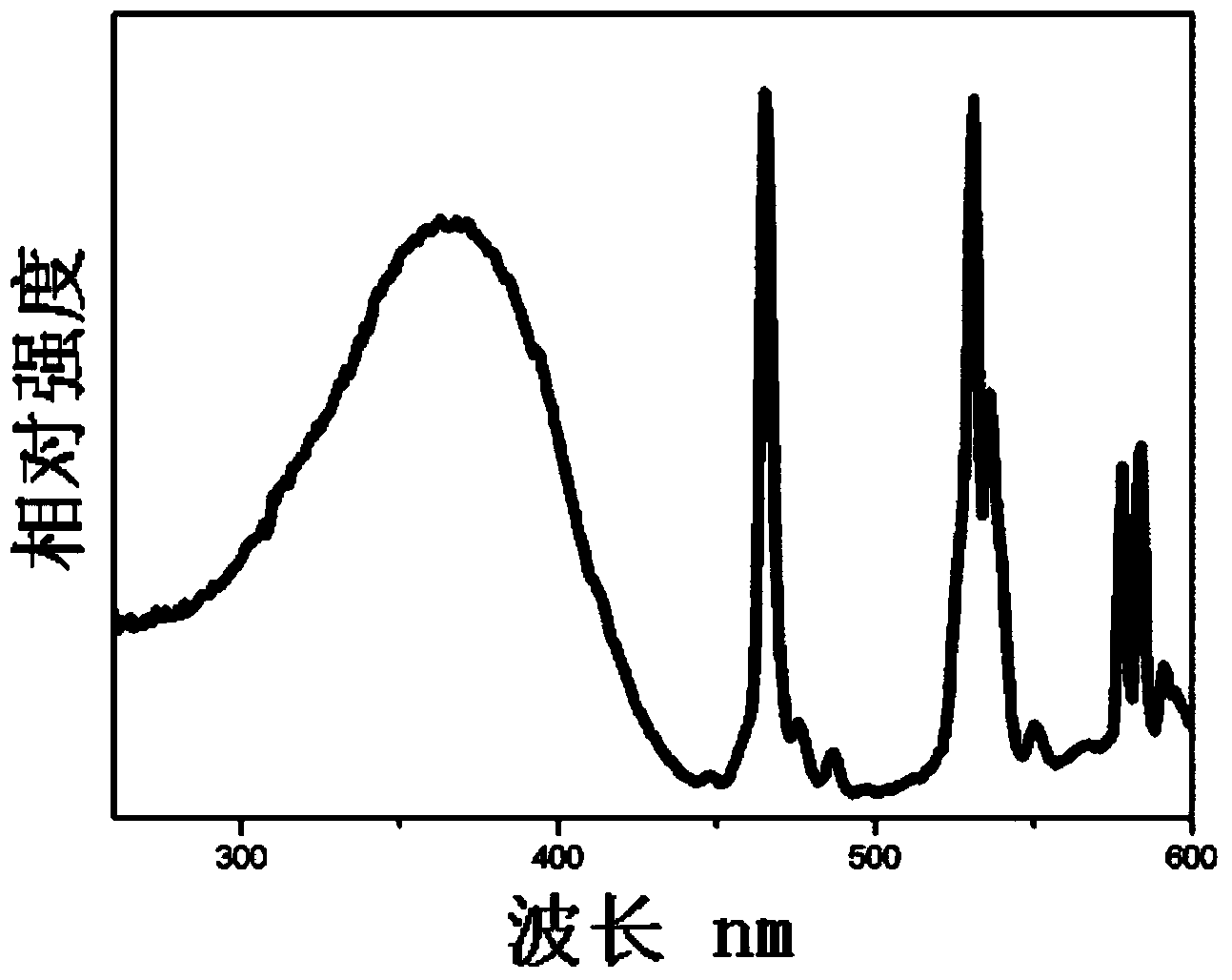

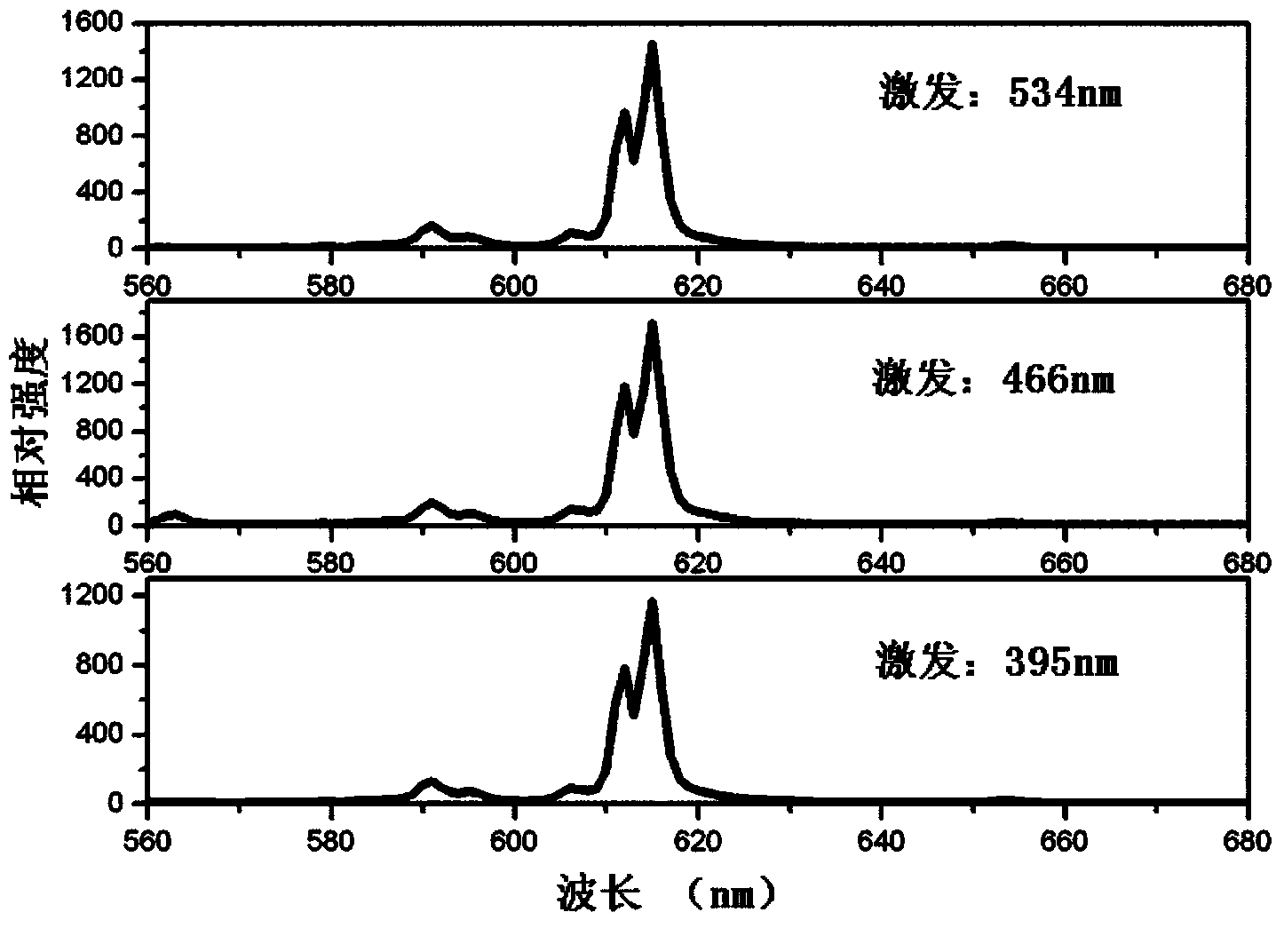

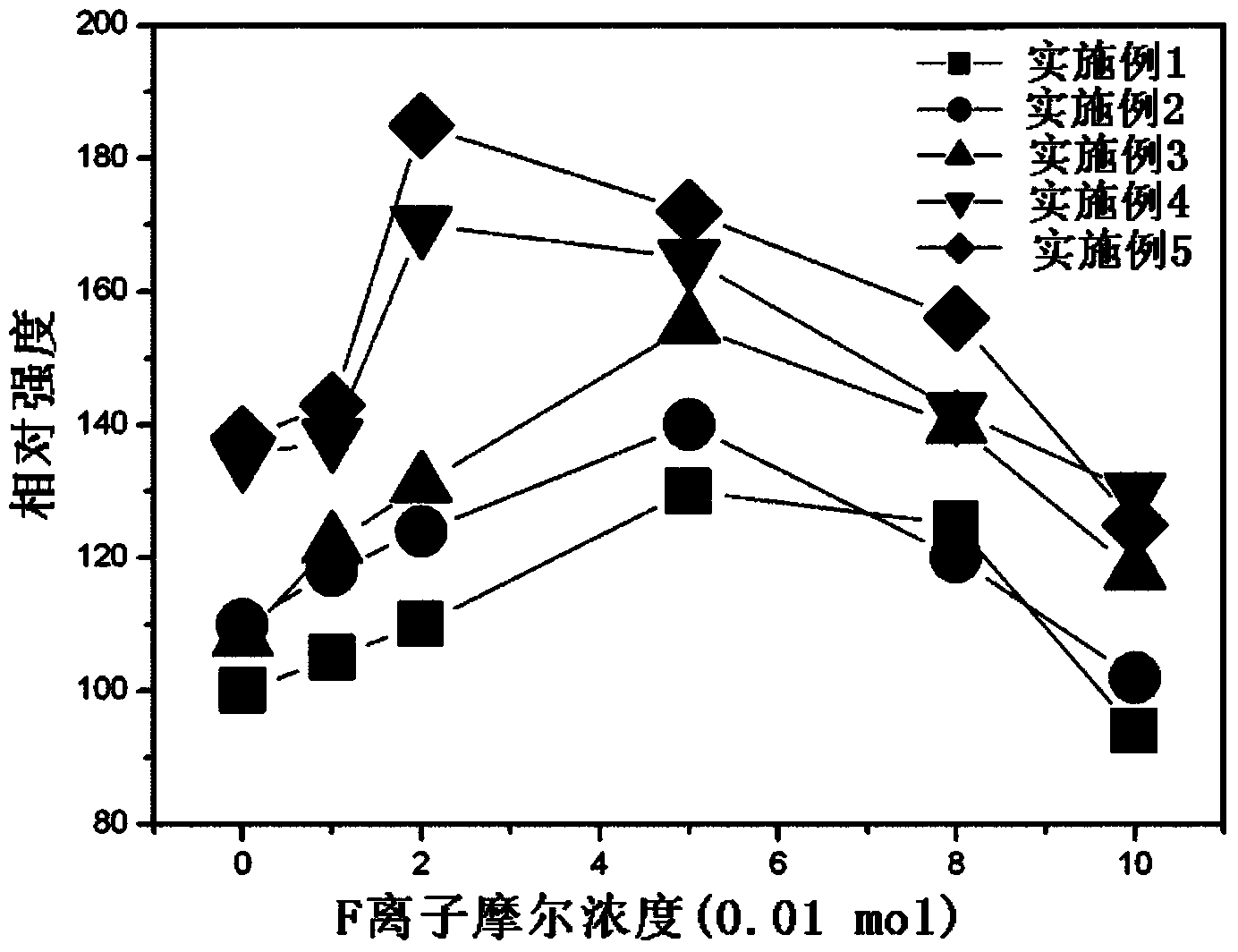

[0034] Weigh various raw materials CaCO according to stoichiometric composition 3 , Li 2 CO 3 , Eu 2 o 3 , MoO 3 , NH 4 F, where NH is weighed 4 The molar masses of F are 0, 0.01, 0.02, 0.05, 0.08, 0.10, that is, the x values are 0, 0.01, 0.02, 0.04, 0.08, 0.10. After the above 6 groups of raw materials are fully ball-milled and mixed evenly, put them into a 99% porcelain crucible, keep warm at 500°C for 5 hours in an air atmosphere, then raise the temperature to 850°C and keep warm for 4 hours, cool the sintered body, crush, sieve, and classify. The chemical composition in the present invention is obtained as Ca 0.8 Eu 0.1 Li 0.1 MoO 4 : NH 4 F fluorescent material. where Ca 0.8 Li 0.1 MoO 3.92 f 0.08 : Eu 0.1 The excitation spectrum of figure 1 As shown, the emission spectra under different excitation light are as figure 2 Its maximum emission is shown at 6...

Embodiment 2

[0035] Example 2: Ca 0.72 Li 0.1 MoO 4-x f x : Eu 0.96 SM 0.04 Preparation of fluorescent materials

[0036] Weigh various raw materials CaCO according to stoichiometric composition 3 , Li 2 CO 3 , Eu 2 o 3 , MoO 3 , SmO 3 , NH 4 F, where NH is weighed 4 The molar masses of F are 0, 0.01, 0.02, 0.05, 0.08, 0.10, that is, the x values are 0, 0.01, 0.02, 0.04, 0.08, 0.10. After the above 6 groups of raw materials are fully ball-milled and mixed evenly, put them into a 99% porcelain crucible, keep warm at 500°C for 5 hours in an air atmosphere, then raise the temperature to 850°C and keep warm for 4 hours, cool the sintered body, crush, sieve, and classify. The chemical composition in the present invention is obtained as Ca 0.72 Li 0.1 O 4-x f x : Eu 0.96 SM 0.04 fluorescent material. Its excitation and emission spectral characteristics are basically consistent with those of Example 1. Different content of NH 4 The effect of F on the luminous intensity at...

Embodiment 3

[0037] Example 3: LiMo 2 o 8-x f 2x : Preparation of Eu fluorescent material

[0038] Weigh various raw materials CaCO according to stoichiometric composition 3 , Li 2 CO 3 , Eu 2 o 3 , MoO 3 , LiF, where the molar mass of LiF is weighed as 0, 0.01, 0.02, 0.05, 0.08, 0.10, that is, the x value is 0, 0.01, 0.02, 0.04, 0.08, 0.10. After the above 6 groups of raw materials are fully ball-milled and mixed evenly, put them into a 99% porcelain crucible, keep warm at 500°C for 5 hours in an air atmosphere, then raise the temperature to 850°C and keep warm for 4 hours, cool the sintered body, crush, sieve, and classify. Obtaining the chemical composition in the present invention is LiMo 2 o 8-x f 2x : Eu fluorescent material. Its excitation and emission spectral characteristics are basically consistent with those of Example 1. The influence of different contents of LiF on the luminous intensity at 615nm is as follows: image 3 Shown in line 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com