A kind of high-efficiency lithium-air battery air electrode carbon material and preparation method thereof

A lithium-air battery and air electrode technology, which is applied in the direction of fuel cell half-cells and primary battery-type half-cells, can solve the problems that are not suitable for lithium-air batteries, and achieve the effect of improving electrochemical performance and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method provided by the invention comprises the steps of:

[0050] (i) adding a nitrogen-containing precursor on the surface of the carbon material of the support layer, so that a polymerization reaction occurs on the surface of the carbon material of the support layer;

[0051] (ii) After the polymerization reaction is completed, perform high-temperature carbonization treatment to obtain the air electrode carbon material;

[0052] Another preparation method provided by the invention comprises the steps of:

[0053](i') fully mixing the carbon material of the support layer with a nitrogen-containing precursor to obtain a mixed material;

[0054] (ii') performing high-temperature carbonization treatment on the mixed material obtained in step i') to obtain the air electrode carbon material.

[0055] The present invention realizes a controllable preparation method of the functional layer / support layer material, that is, an all-covering synthesis method, wh...

Embodiment 1

[0062] 1.1 Preparation of composite carbon material 1

[0063] Weigh 1.0g commercial carbon material Ketjen black (KB-EC600JD) (specific surface area 2672m 2 / g) into methanol, stirring-ultrasonic dispersion to obtain a uniform Ketjen Black methanol suspension, and put the beaker containing the suspension into an ice-water bath. Then add 1.2 g of aniline to 0.5 mol / L sulfuric acid solution to form a sulfuric acid solution of aniline, and at the same time prepare a sulfuric acid solution of ammonium persulfate (molar ratio 1:1), and add them dropwise to Ketjen Black methanol suspension. After stirring and reacting for 6 hours, the product was suction-filtered and vacuum-dried at 60° C. to obtain a polyaniline-ketjen black composite material. The synthesized composite material was transferred to a crucible, and sintered in a tube furnace at 900° C. for 3 hours under a high-purity nitrogen atmosphere to obtain a composite carbon material 1 .

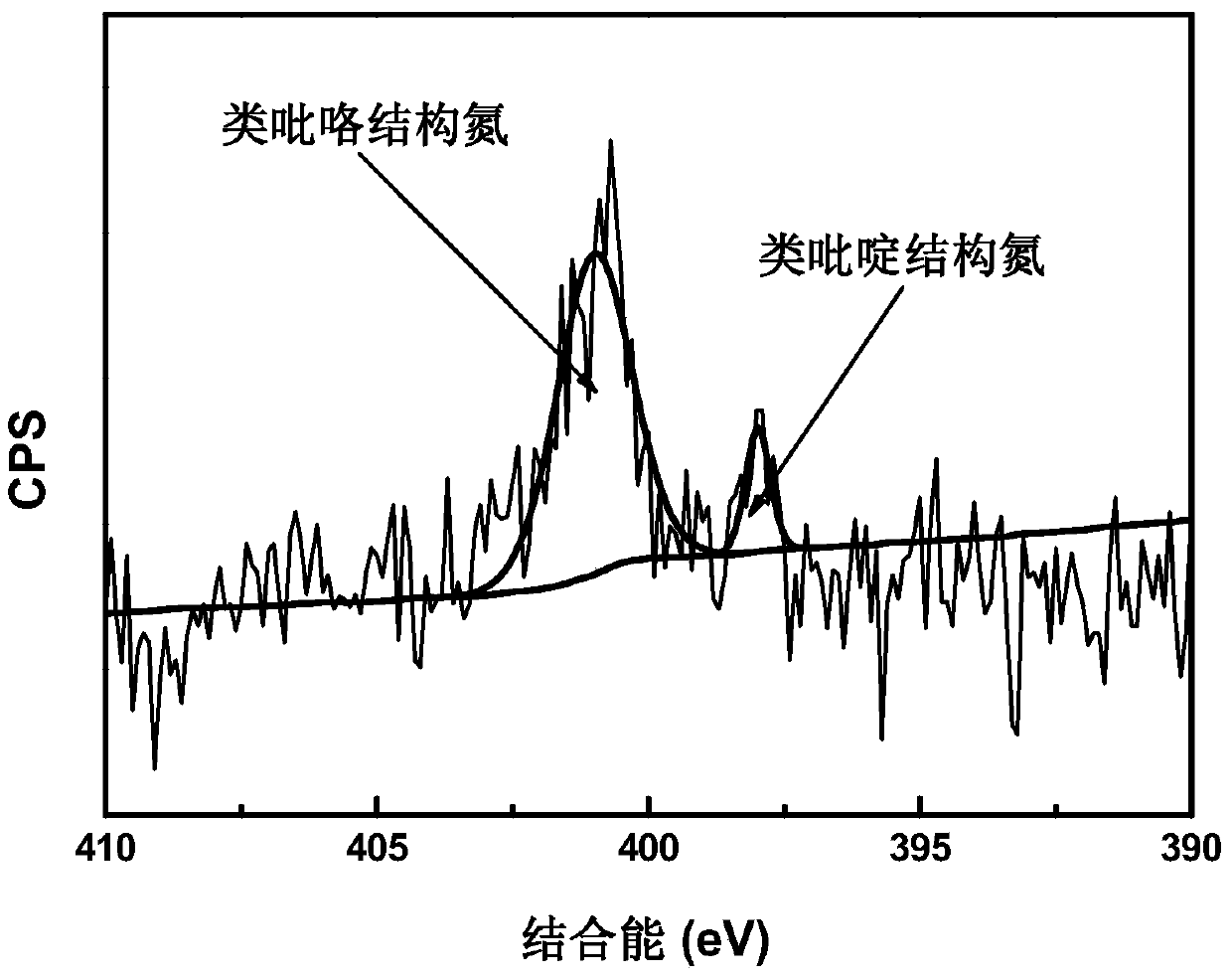

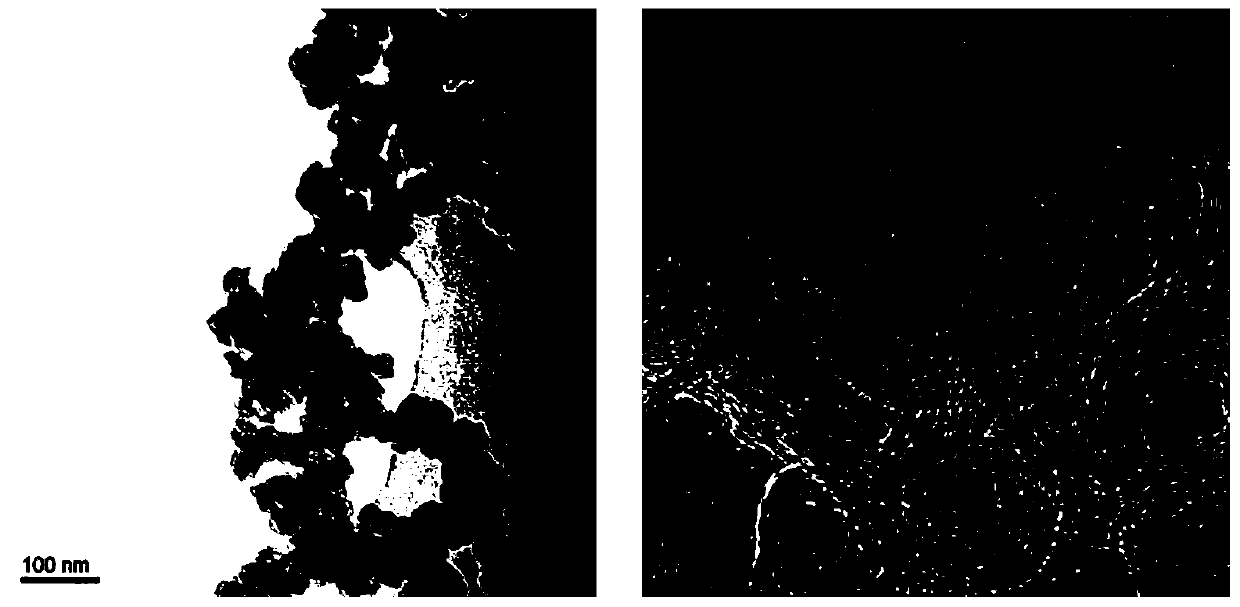

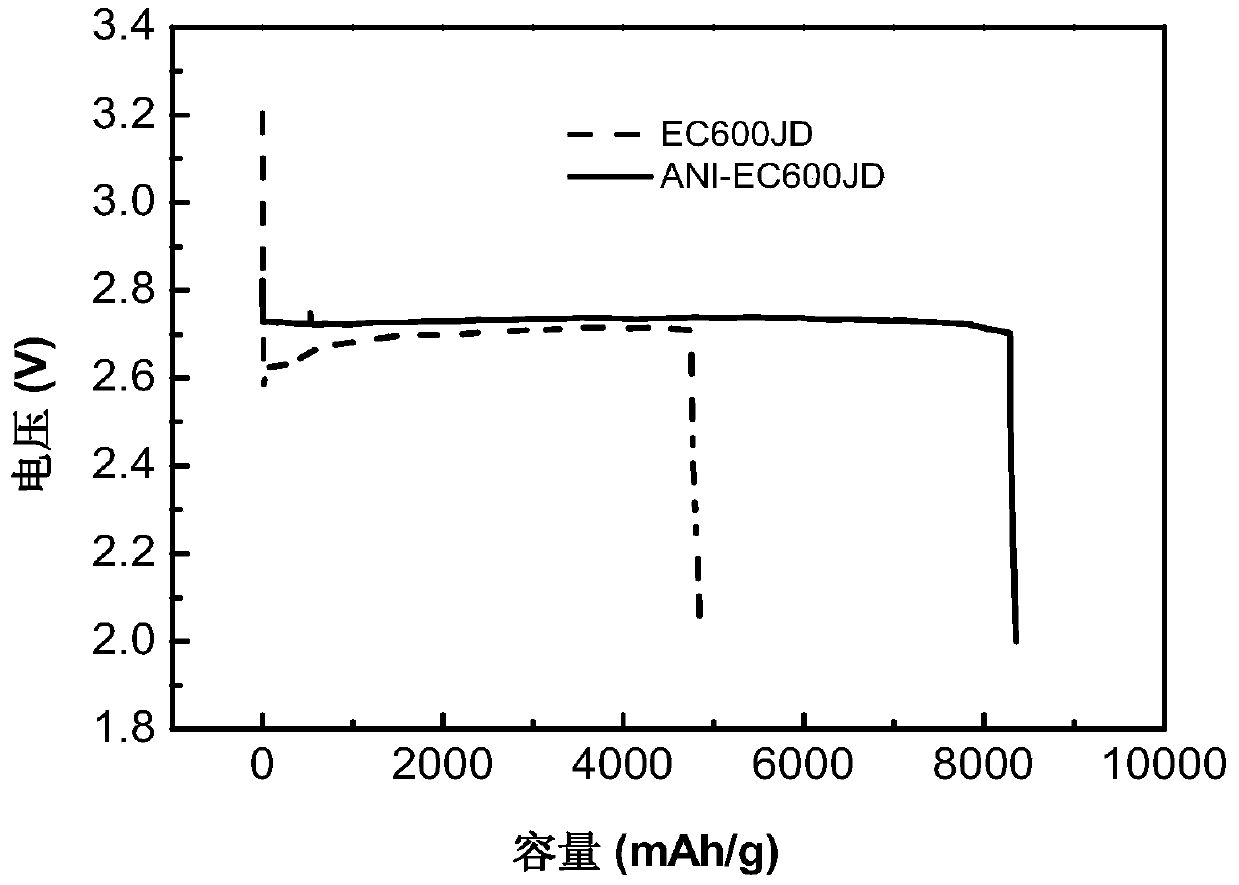

[0064] The X-ray photoelectron spe...

Embodiment 2

[0075] Weigh 0.5g KB-EC600JD and add it into methanol, stir-ultrasonic dispersion to obtain a uniform suspension of Ketjen Black in methanol, and put the beaker containing the suspension into an ice-water bath. Then add 3.0 g of aniline to 0.5 mol / L sulfuric acid solution to form a sulfuric acid solution of aniline, and at the same time prepare a sulfuric acid solution of ammonium persulfate (molar ratio 1:1), and add them dropwise to Ketjen Black methanol suspension. After stirring and reacting for 6 hours, the product was suction-filtered and vacuum-dried at 60° C. to obtain a polyaniline-ketjen black composite material. The synthesized composite carbon material was transferred to a crucible, and sintered in a tube furnace at 900° C. for 3 hours under a high-purity nitrogen atmosphere to obtain a composite carbon material 2 .

[0076] The preparation of the air electrode, the assembly of the lithium-air battery, and the charging and discharging test methods are the same as i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com