Method for improving burley tobacco availability

A usability and burley tobacco technology, which is applied in the tobacco industry, can solve the problems of high nicotine content, low proportion of formula used, and difficult to cover up, so as to reduce starch content and protein content, reduce the smell and strength of air-cured tobacco, Weaken the effect of fragrance style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

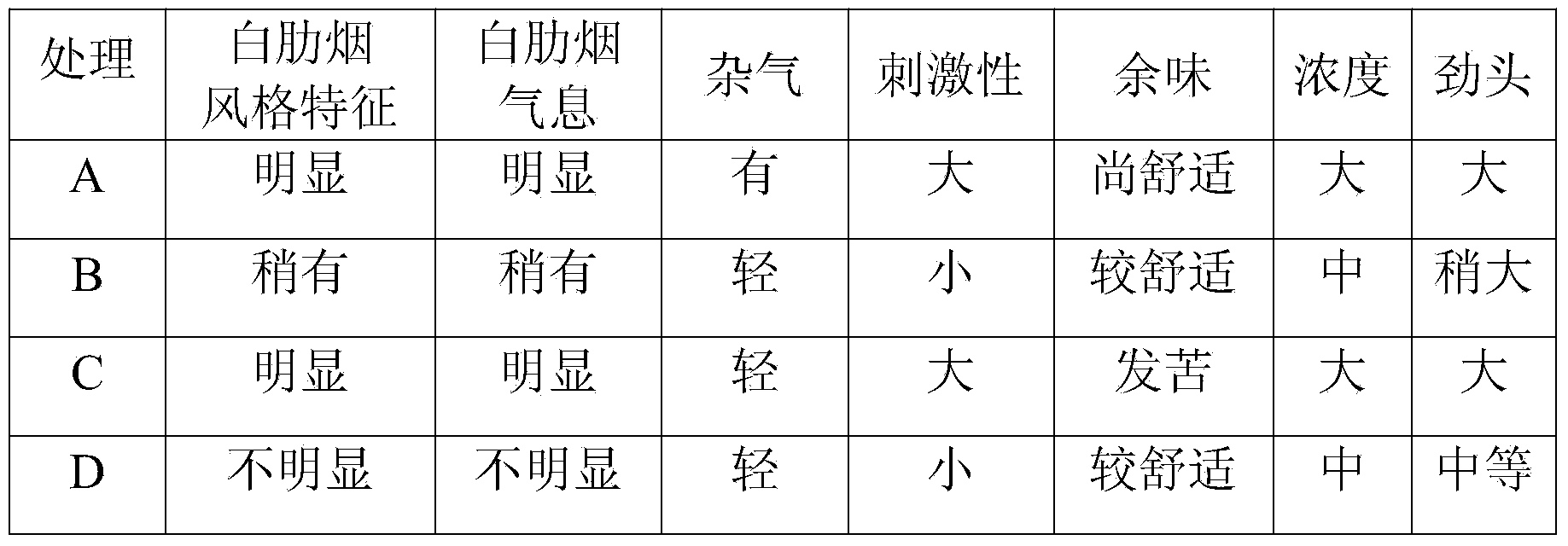

[0016] Embodiment: In order to popularize the method for improving the availability of burley tobacco of the present invention, the method of the present invention has been tested in Enshi Redrying Factory in Hubei Province. Enshi Redrying Factory has advanced equipment, standardized management, and a high level of production technology for leaf threshing and redrying , The processing capacity of the threshing and redrying production line is 12000kg / hour. The materials used are: the rebaking material provided by the present invention, two grades of C2F and C3F tobacco leaves from Hubei Enshi Construction in 2011.

[0017] This test establishes 4 treatments, and C2F grade tobacco leaves are provided with two treatments: feeding and no feeding; C3F grade tobacco leaves are also provided with two treatments: feeding and no feeding; no feeding treatment is produced according to the normal process parameter requirements, and feeding treatment is according to the present invention S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com