Industrial tail gas treatment complete equipment of carbon fiber reinforced graphite

A technology for industrial tail gas and complete sets of equipment, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems that the hazard of hydrochloric acid tail gas cannot be completely eliminated, and the function is single, and achieve clean and thorough treatment, high mechanical strength, and high performance. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

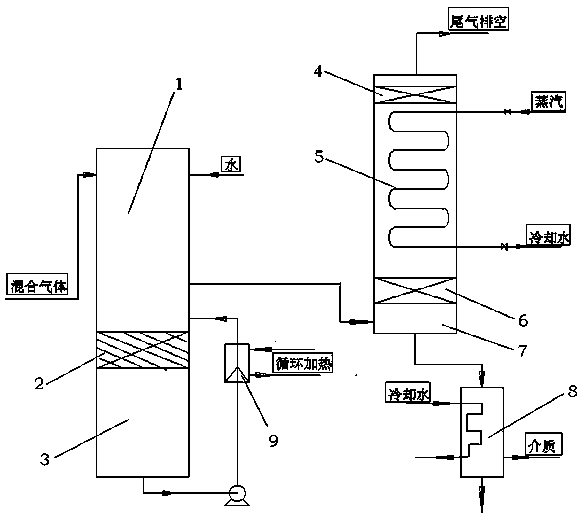

[0017] The complete set of industrial tail gas treatment equipment for carbon fiber reinforced graphite as shown in the attached figure has a falling film absorption tower 1, a packed tower 7, and a cooling tower 8, which are used for the treatment of tail gas from hydrochloric acid synthesis.

[0018] In the falling film absorption tower 1, the part in contact with the tail gas is made of full carbon fiber reinforced graphite; the inner wall of the part in contact with the solution is made of graphite or carbon fiber reinforced graphite, and the outer wall is made of stainless steel plate.

[0019] The upper part of the falling film absorption tower 1 has tail gas inlet and absorption water inlet, and the lower part of the falling film absorption tower is connected with a solution tank 3 . The place above the liquid level in the solution tank 3 has an organic gas outlet, and the place below the liquid level in the solution tank 3 is connected with a solution heating and therma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com