Method for testing pore diameter distribution of ultra-filtration membrane

A technology of ultrafiltration membrane and pore size, which is applied in the fields of semi-permeable membrane separation, chemical instruments and methods, suspension and porous material analysis, etc. It can solve the problems that ultrafiltration membrane pore size analyzers are rare, etc., and achieve simple operation and improved The degree of automation and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

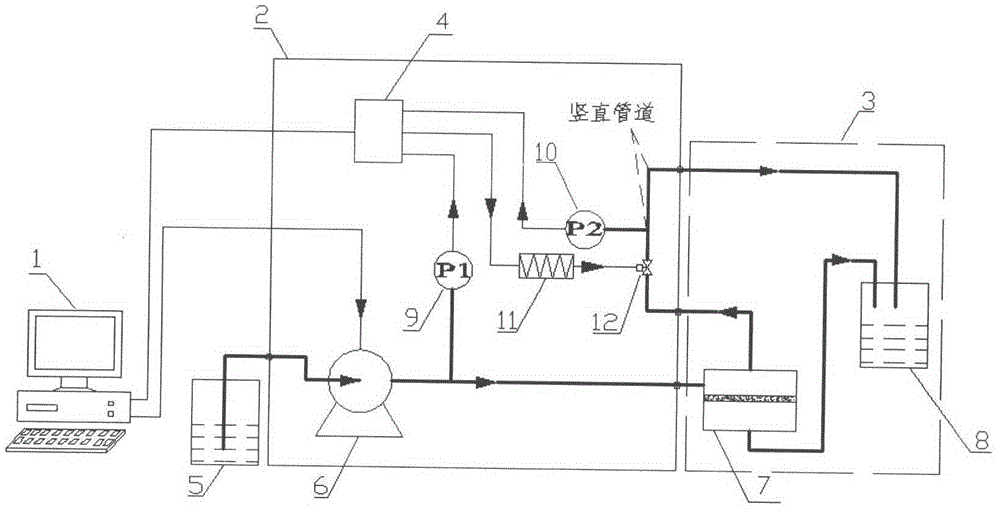

Method used

Image

Examples

Embodiment example 1

[0036] 1. Mix isobutanol and deionized water in equal volumes. After standing and stratifying, the upper oil phase is used as the immersion liquid, and the water phase is used as the replacement liquid. The interfacial tension between the immersion liquid and the replacement liquid is 1.7mN / m at 20°C.

[0037] 2. Put the membrane into the module (7), seal it and fix it, open the test software, set the maximum pressure to 150kPa, the maximum flow rate to 3ml / min and the flow increase rate of the constant flow pump to 0.01ml / min, click to start the test.

[0038] 3. The software automatically opens the solenoid valve (12), and makes the constant flow pump (6) enter the liquid at a relatively large flow rate, and the replacement liquid gradually fills the stainless steel pipeline, the membrane module (7) and the cavity of the pressure transmitter, and its system When the replacement fluid reaches the vertical pipeline, the pressure sensor 2 (10) will sense a certain pressure due t...

Embodiment example 2

[0046] 1. Mix equal volumes of n-pentanol and deionized water, and after standing for stratification, the upper oil phase is used as the immersion liquid, and the water phase is used as the replacement liquid. The interfacial tension between the immersion liquid and the replacement liquid is 4.8mN / m at 20°C.

[0047] 2. Except that the maximum pressure is set to 400kPa and the maximum flow rate is 4ml / min, the rest of the operation steps are the same as the implementation case 1. Finally, the maximum pore size of the ultrafiltration membrane was calculated to be 163.6nm, and the average pore size was 77nm.

Embodiment example 3

[0049] 1. Mix water, methanol, and isobutanol at a volume ratio of 25:7:15. After standing for stratification, the upper oil phase is used as the immersion liquid, and the water phase is used as the replacement liquid. The interfacial tension between the immersion liquid and the replacement liquid at 20°C is 0.35mN / m.

[0050] 2. Except that the maximum pressure is set to 300kPa and the maximum flow rate is 3ml / min, the rest of the operation steps are the same as the implementation case 1. Finally, the maximum pore size of the ultrafiltration membrane is calculated to be 32nm, and the average pore size is 11.8nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com