Seed dust removal and impurity removal device and working method thereof

A working method and seed technology, which is applied in the field of crop seed processing and storage, can solve the problems of affecting the quality of seeds, cumbersome and inefficient dust cleaning work, and low efficiency of manual dust cleaning, so as to achieve simple operation, long-term preservation and high-efficiency utilization , the effect of good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

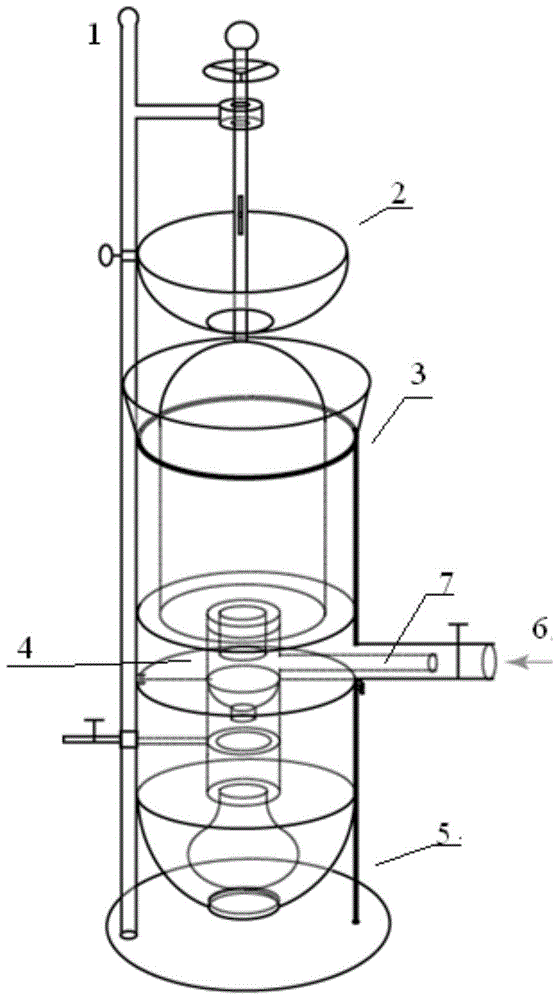

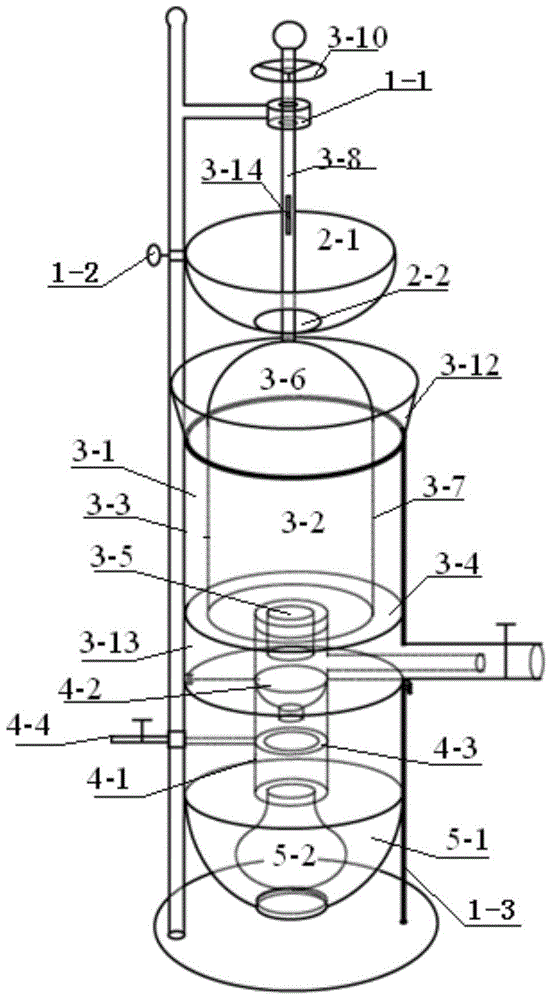

[0053] The seed dust removal and impurity removal device includes a bracket 1, on which the material collecting part 2, the friction dust cleaning part 3, the classifying wind separation part 4 and the material receiving part 5 are fixedly arranged sequentially from top to bottom;

[0054] The material collection part 2 includes an arc-shaped container 2-1, and a blanking through hole 2-2 is provided through the bottom of the arc-shaped container 2-1;

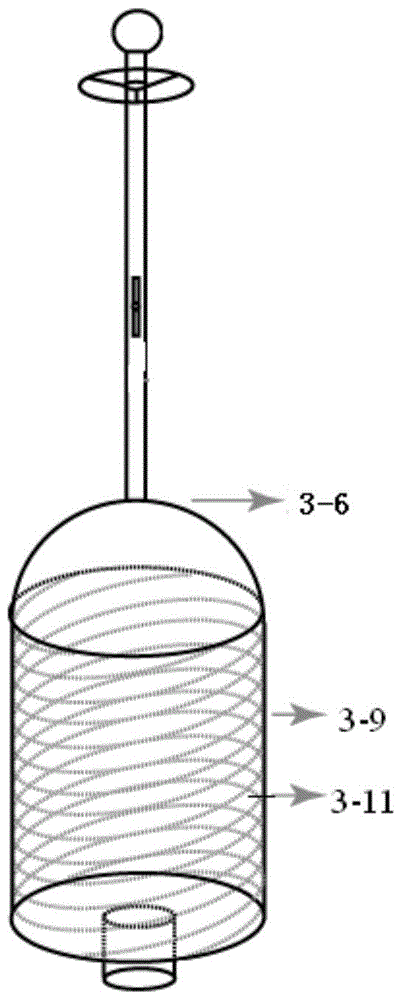

[0055] The friction cleaning part 3 includes a barrel-shaped friction cavity 3-1, and a friction cover 3-2 is axially arranged inside the barrel-shaped friction cavity 3-1; the barrel-shaped friction cavity 3-1 includes a barrel The wall 3-3 and the funnel screen 3-4 are provided with a seed through hole 3-5 at the bottom of the funnel screen 3-4; the friction cover 3-2 includes an arc-shaped top cover 3-6 And the cover wall 3-7, a friction rotating rod 3-8 is fixedly arranged on the top of the arc-shaped top cover 3-6, and the...

Embodiment 2

[0060] The difference of the device for removing dust and impurities from seeds as described in Embodiment 1 is that an auxiliary bracket 1-3 is provided outside the barrel-shaped friction chamber 3-1.

Embodiment 3

[0062] The difference of the seed dust removal and impurity removal device as described in embodiment 1 is that a bearing sleeve is arranged on the upper part of the support for fixing the friction rotating rod. A ring handle is arranged on the upper part of the friction rotating rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com