Automatic high temperature chloride corrosion resisting layer surfacing device of irregular surface and surfacing method

A technology of automatic surfacing and high temperature resistance, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems that the quality cannot be guaranteed, the cladding layer is prone to defects, and the surface of the finished product is uneven, so as to improve the quality of the product. The effect of quality and production efficiency, good consistency and constant distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

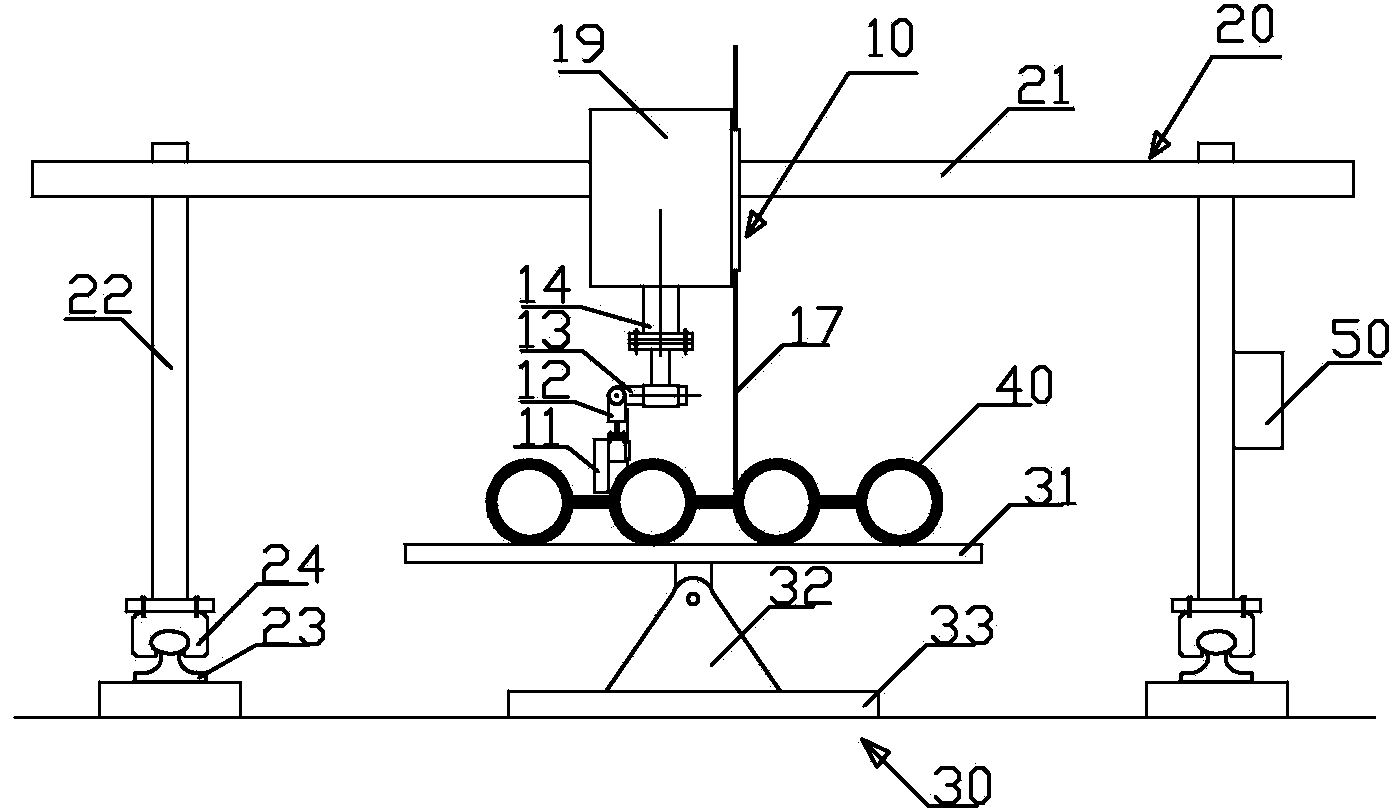

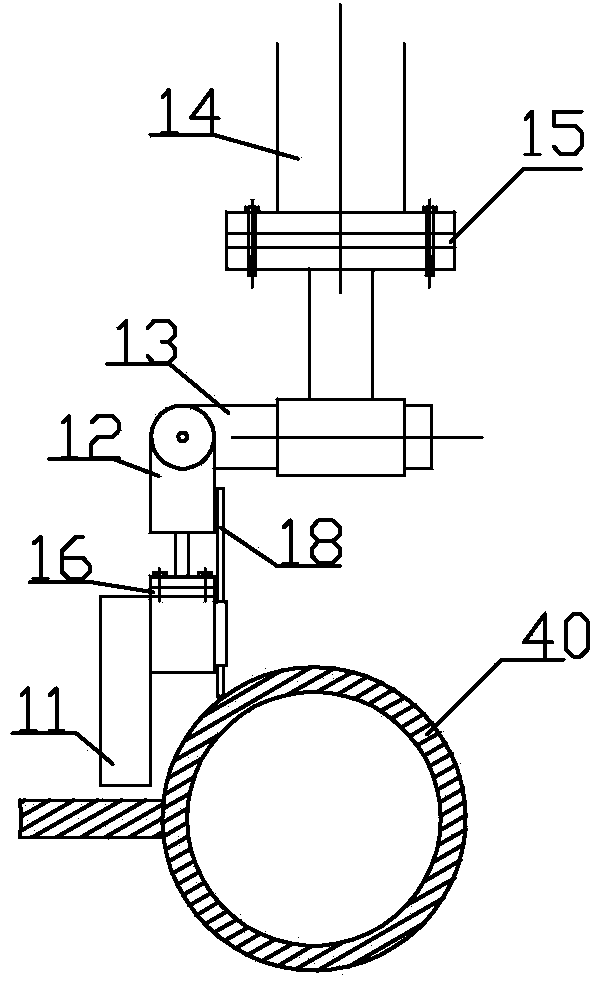

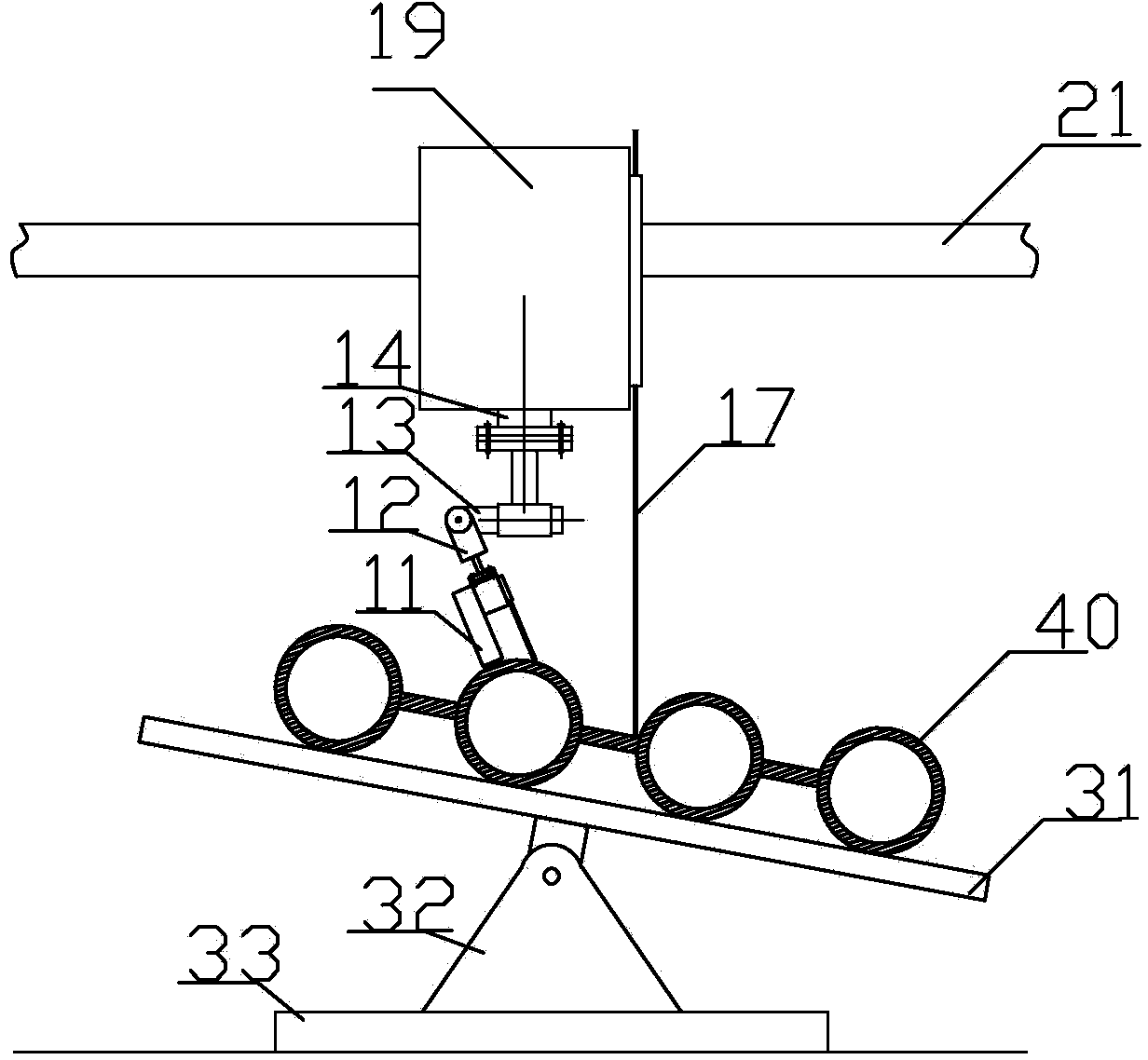

[0041] The automatic surfacing device for the high temperature chlorine corrosion resistant layer on the irregular surface includes a frame 20, the frame 20 is provided with a positioning device and at least one positioning belt surfacing head assembly 10, and the positioning belt electrode surfacing head assembly 10 can be positioned along the frame 20 moves horizontally, and at least includes a workpiece seat 30, the workpiece seat 30 can rotate the workpiece placed on it at a certain angle, and the positioning belt electrode surfacing head assembly 10 includes positioning the belt electrode surfacing head 11 and adjusting and positioning the belt electrode surfacin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com