A kind of liquid crystal compound and its preparation method and application

A technology of compound and carbon number, applied in the field of organic synthesis and liquid crystal materials, can solve the problems of complex synthesis methods, poor solubility, difficult to preserve, etc., and achieve the effects of high overall yield, simple preparation, and correct nuclear magnetic detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1, compound preparation of

[0040]

[0041] Into a 100mL microwave reactor, put 3.0mmol of 1,2,5-trimethylpyrrole and 9.0mmol of FeCl 3 React with 40mL of dichloromethane at 500w at 30°C for 5min. Pour the system into 200mL aqueous solution and stir for 10 minutes. The liquids were separated, the aqueous phase was extracted three times with 15 mL of dichloromethane, the organic phases were washed with water, combined and spin-dried to obtain a yellow liquid. Pass through a silica gel column and rinse with ethyl acetate to obtain a yellow liquid product, yield: 56%.

[0042] 1 H NMR (CDCl 3 ,300MHz): δ=3.59(s,9H),2.46(s,18H).

[0043] 13 C NMR (CDCl 3 ,75MHz): δ=133.8,106.2,33.0,10.5.

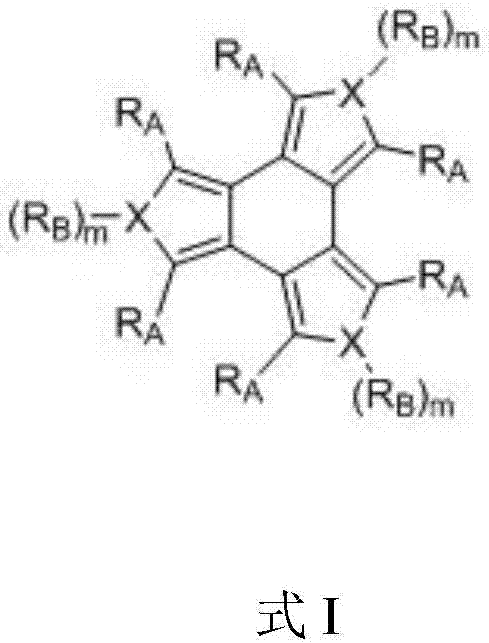

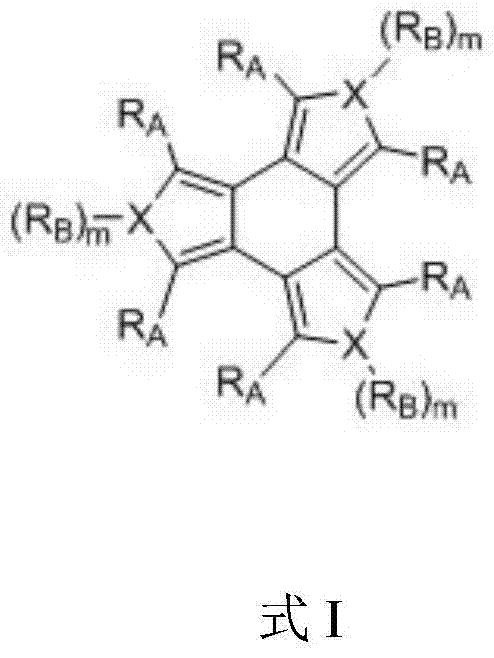

[0044] As can be seen from the above, the structure of the white solid product is correct, and it is a compound shown in formula I

[0045]

Embodiment 2

[0046] Embodiment 2, compound Synthesis

[0047]

[0048] Into a 100mL microwave reactor, put 3.0mmol of 2,5-diethylthiophene and 3.0mmol of FeCl 3 React with 40mL of dichloromethane at 500w at 30°C for 5min. Pour the system into 200mL aqueous solution and stir for 10 minutes. The liquids were separated, the aqueous phase was extracted three times with 15 mL of dichloromethane, the organic phases were washed with water, combined and spin-dried to obtain a yellow liquid. Pass through a silica gel column and rinse with ethyl acetate to obtain a yellow liquid product with a yield of 62%.

[0049] 1 H NMR (CDCl 3 ,300MHz): δ=2.87(q,12H),1.25(t,18H).

[0050] 13 C NMR (CDCl 3 ,75MHz): δ=149.2,124.6,21.1,13.5.

[0051] As can be seen from the above, the structure of the white solid product is correct, and it is a compound shown in formula I

[0052]

Embodiment 3

[0053] Embodiment 3, compound Synthesis

[0054] step 1: Synthesis

[0055]

[0056] Put 100mmol of thiophene and 100mL of tetrahydrofuran into a 250mL reaction flask, and cool the system to -78°C under nitrogen protection. Keep -78°C and add 150mmol of butyllithium dropwise, and keep -78°C for 1 hour after dropping. Keep -78°C and add 150 mmol of p-bromoanisole dropwise. After the drop, keep -78°C for 2 hours and slowly rise to room temperature to react overnight. Add 100 mL of water and 100 mL of ethyl acetate to the system, stir and separate the liquids, extract the aqueous phase twice with 30 mL of ethyl acetate, wash the organic phase twice with 20 mL of water, combine the organic phases, and spin dry to obtain a yellow solid. After passing through a silica gel column and eluting with ethyl acetate:petroleum ether=4:1, a yellow solid product was obtained with a yield of 77%.

[0057] Step 2: Synthesis

[0058]

[0059] Into a 100mL microwave reactor, put 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com