Method for supercritical fluid extraction of taxus chinensis seed volatile oil

A southern yew, supercritical technology, applied in essential oils/fragrances, fat production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

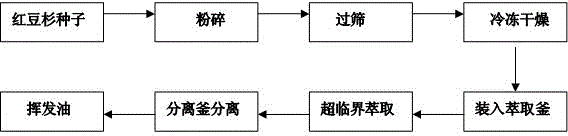

Method used

Image

Examples

Embodiment 1

[0027] (1) Grinding: Grinding the seeds of Taxus chinensis to a particle size of 20 mesh and sieving.

[0028] (2) Freeze-drying: freeze-dry the pulverized material at -50°C for 4 hours.

[0029] (3) Supercritical extraction: put the freeze-dried raw materials into the extraction kettle for extraction, and the filling factor is 80%. The extraction conditions are: extraction pressure 25MPa, extraction temperature 50°C, extraction time 4h, temperature of one separation tank 30°C, pressure 8MPa, temperature of the other separation tank 30°C, pressure 8MPa.

[0030] (4) Separation: After the extraction is completed, the obtained liquid is released from the two separation kettles, which is the volatile oil of Taxus chinensis seeds. After weighing, the yield of volatile oil is 27.4%.

Embodiment 2

[0032] (1) Grinding: Grinding the seeds of Taxus chinensis to a particle size of 40 mesh and sieving.

[0033] (2) Freeze-drying: freeze-dry the pulverized material at -45°C for 5 hours.

[0034] (3) Supercritical extraction: put the freeze-dried raw materials into an extraction kettle for extraction, and the filling factor is 90%. The extraction conditions are: extraction pressure 20MPa, extraction temperature 45°C, extraction time 3h, temperature of one separation tank 35°C, pressure 6MPa, temperature of the other separation tank 35°C, pressure 6MPa.

[0035] (4) Separation: After the extraction is completed, the obtained liquid is released from the two separation kettles, which is the volatile oil of Taxus chinensis seeds. The yield of volatile oil is 25.8% after weighing.

Embodiment 3

[0037] (1) Grinding: Grinding the seeds of Taxus chinensis to a particle size of 30 mesh and sieving.

[0038] (2) Freeze-drying: freeze-dry the pulverized material at -40°C for 6 hours.

[0039] (3) Supercritical extraction: put the freeze-dried raw materials into an extraction kettle for extraction, and the filling factor is 90%. The extraction conditions are: extraction pressure 15MPa, extraction temperature 40°C, extraction time 2h, temperature of one separation tank 40°C, pressure 10MPa, temperature of the other separation tank 40°C, pressure 10MPa.

[0040] (4) Separation: After the extraction is completed, the obtained liquid is released from the two separation kettles, which is the volatile oil of Taxus chinensis seeds. The yield of volatile oil is 23.8% after weighing calculation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com