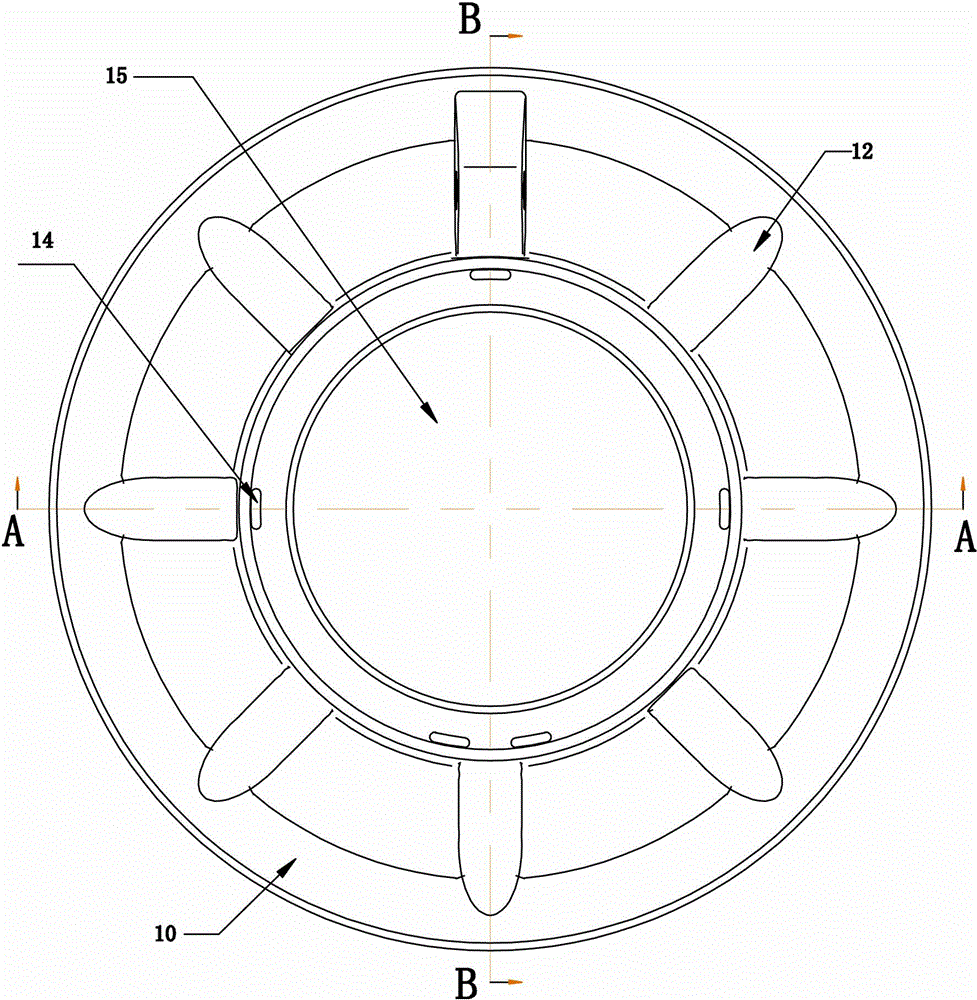

Shoring stabilization device

A technology of stabilizing device and column shoe, which is applied to pillars/supports, mining equipment, earth-moving drilling, etc., can solve the problems of affecting safety and stability, easily generating blisters, increasing the weight of column shoes, etc., so as to improve installation efficiency and Safety and reliability, avoiding delamination and relative displacement, improving safety and aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

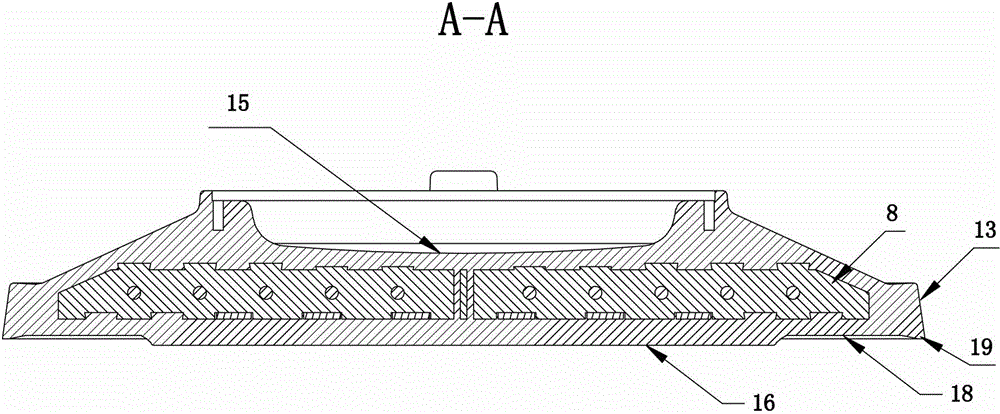

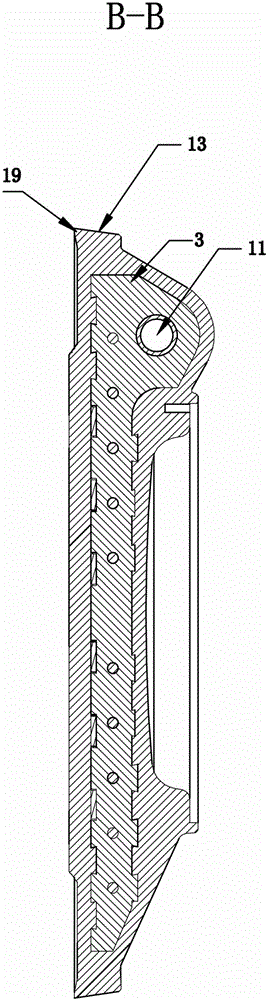

[0060] Now insert the main plate rib 3 and the main plate rib protrusion 7 on the reinforcing plate 8 into the main plate rib groove 2 in the bottom plate 1 in a tight fit, the main plate rib 3 and the reinforcing plate 8 become a centered outward diffusion type and form a vertical state with the bottom plate 1, according to The compressive strength requires increasing the number of reinforcing plates 8 . After the bottom plate 1, the main board ribs 3, and the reinforcement plate 8 form an integral structure, they are put into a plastic mold, and the plastic materials are filled into the skeleton through injection molding, casting, pouring, die-casting and other processes, because the bottom plate 1, the main board ribs 3 1. Anti-skid teeth 5, reinforcement holes 6, and feed holes 9 are designed on the reinforcing plate 8 to prevent delamination and separation of the bottom plate 1, the main board rib 3, and the reinforcing plate 8 in the support column shoes after being press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com