Biomass heating boiler system

A technology of biomass boilers and heating boilers, which is applied in the field of boiler heating, can solve the problems of high energy consumption, achieve quick maintenance, reduce energy consumption, and save labor investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

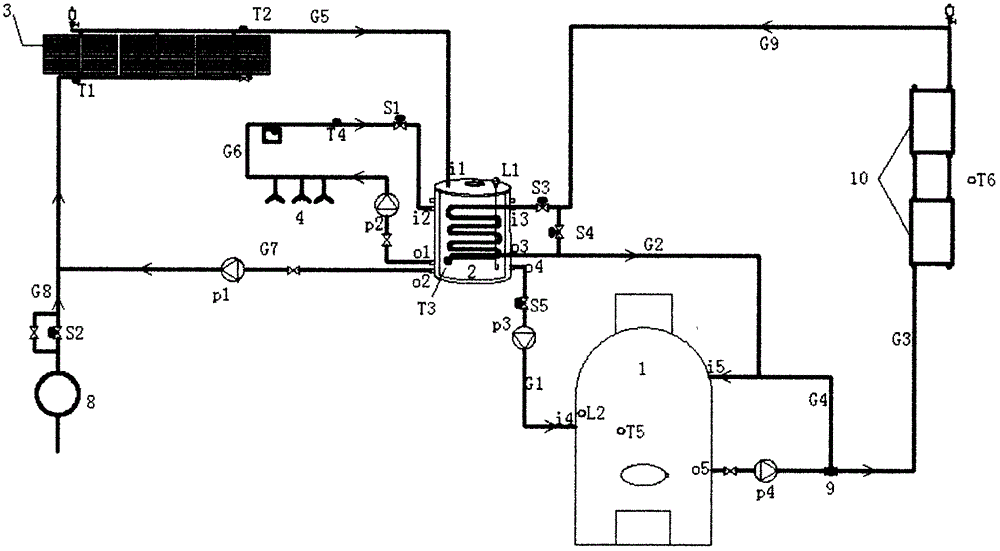

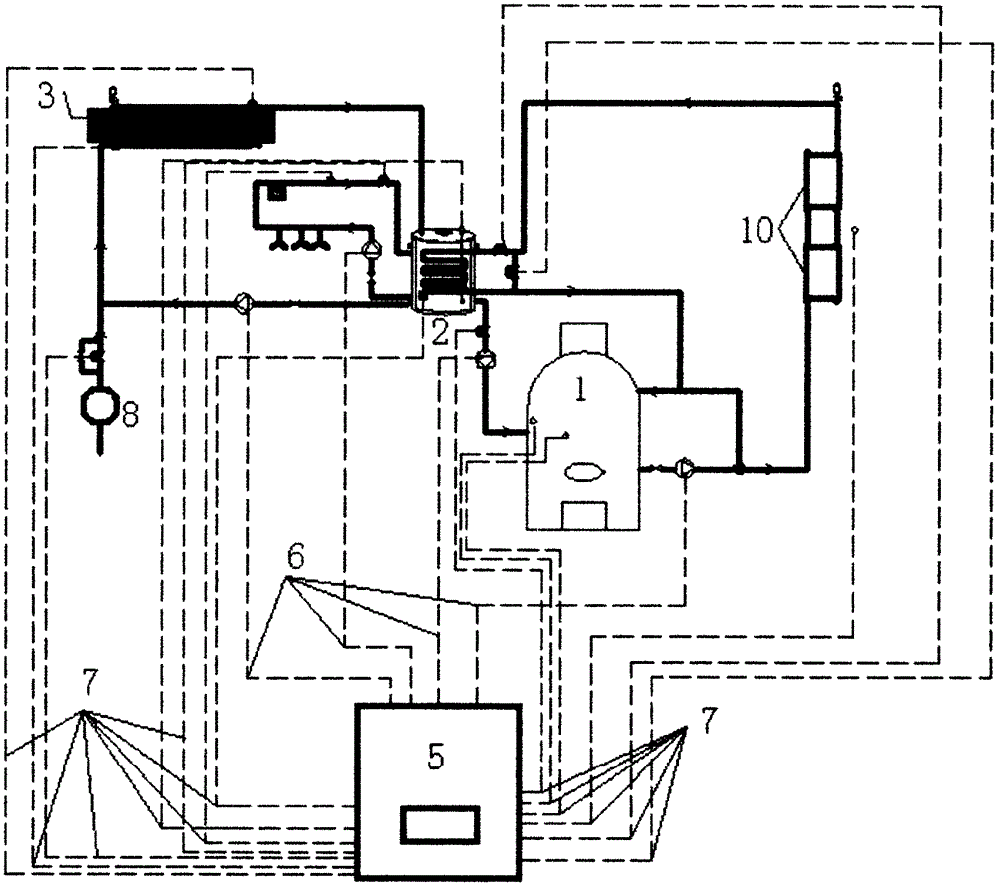

[0040] A kind of biomass heating boiler system of the present invention, its specific implementation see Figure 1 to Figure 2 , including a biomass boiler 1, a water tank 2, a radiator 10, a heat collector 3, a solenoid valve and pipelines, the water tank 2 includes a water tank body and a water tank cover thereon, the water tank cover is provided with a first water inlet i1, and the water tank The bottom of the tank is respectively provided with the first water outlet o1, the second water outlet o2, the third water outlet o3 and the fourth water outlet o4, and the upper part of the water tank is provided with the second water inlet i2 and the third water inlet i3. There is a water tank coil connecting the third water inlet i3 and the third water outlet o3; the biomass boiler 1 is provided with the fourth water inlet i4, the fifth water inlet i5 and the fifth water outlet o5; the pipeline includes the first Pipeline G1, Second Pipeline G2, Third Pipeline G3, Fourth Pipeline G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com