Manufacturing method of iron powder core blank and manufacturing method of iron powder core

A manufacturing method and technology of iron powder core, which are applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of difficulty in controlling the stability of insulation resistance and anti-rust ability, uneven coating of plexiglass, Affect the adhesion of iron powder core electrodes and other problems, and achieve the effect of high degree of automation, less labor, and consistency guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

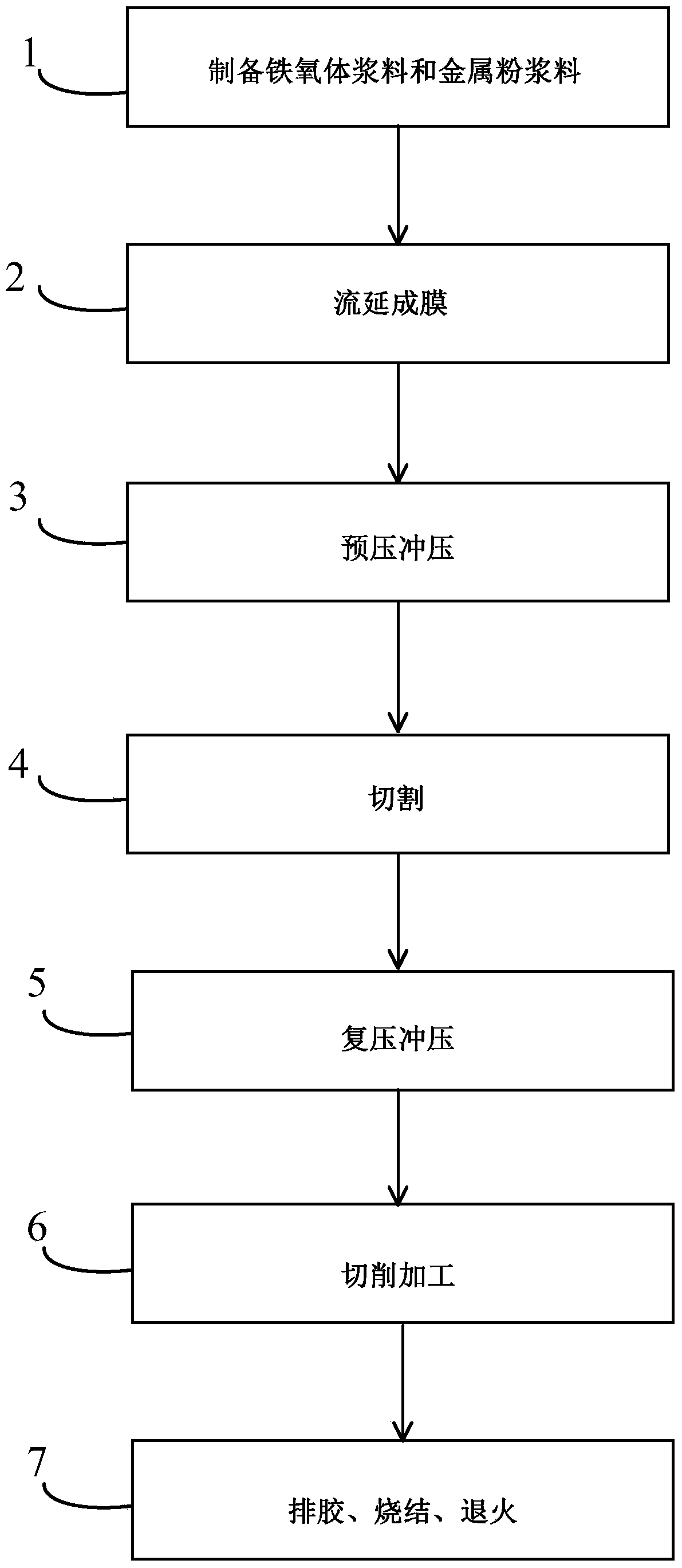

Method used

Image

Examples

experiment example 1

[0037] The ferrite slurry for tape casting is composed of the following components in weight percentage:

[0038] Ferrite powder 90%

[0039] Binder 10%

[0040] The metal powder slurry for tape casting is composed of the following components in weight percentage:

[0041] Metal powder 90%

[0042] Binder 10%

[0043] Wherein, the ferrite powder consists of the following components by weight percentage:

[0044]

[0045] Described metal powder is made up of the component of following percentage by weight:

[0046] Iron 95%

[0047] Silicon 2.5%

[0048] Chromium 2.5%

[0049] Described binding agent is made up of the component of following percentage by weight:

[0050]

[0051]

[0052] According to the above weight percentages, they were mixed into a ball mill for mixing, and the frequency of the ball mill was set to 25 Hz and the time was 24 hr to prepare uniform ferrite slurry and metal powder slurry respectively.

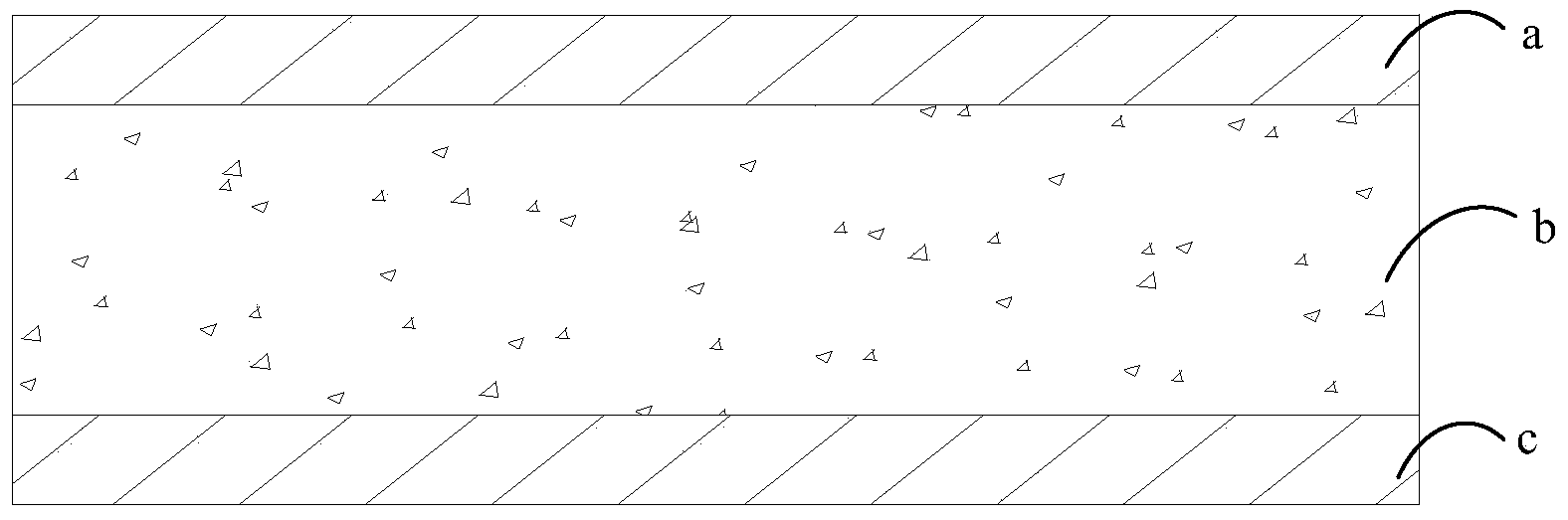

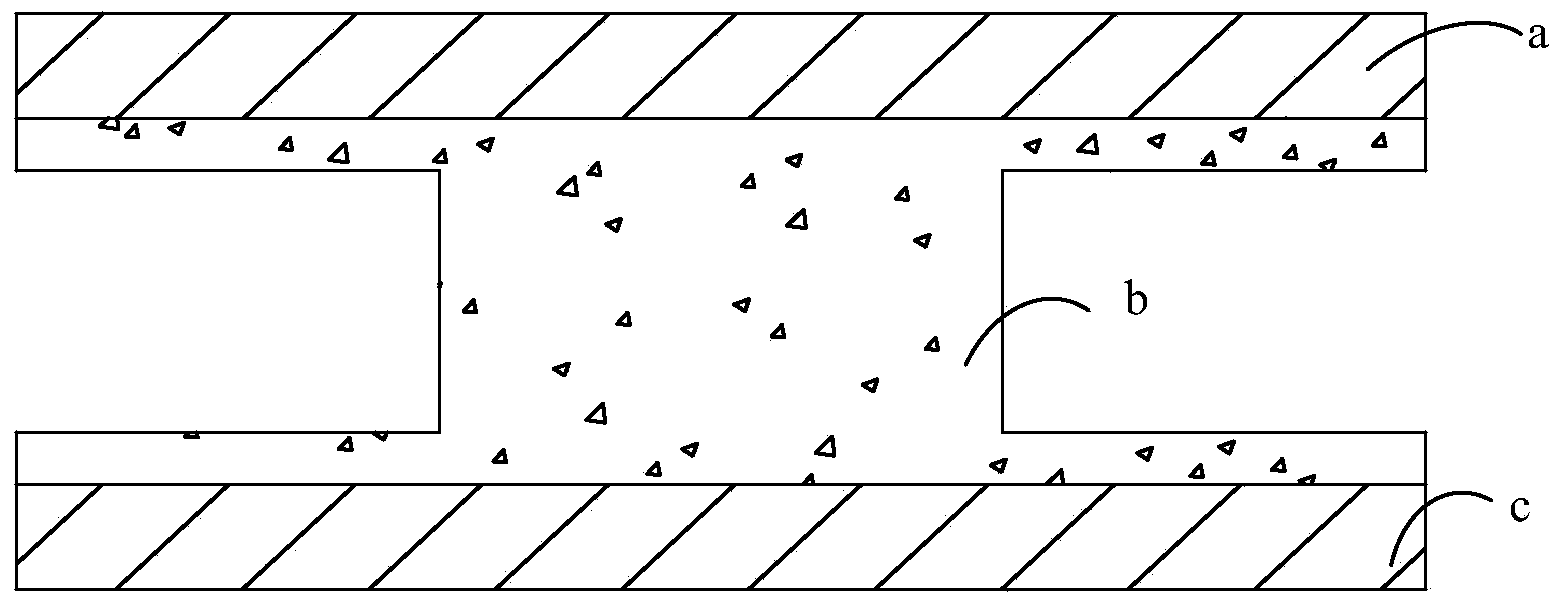

[0053] The ferrite slurry and the metal...

experiment example 2

[0066] The ferrite slurry for tape casting is composed of the following components in weight percentage:

[0067] Ferrite powder 85%

[0068] Binder 15%

[0069] The metal powder slurry for tape casting is composed of the following components in weight percentage:

[0070] Metal powder 85%

[0071] Binder 15%

[0072] Wherein, the ferrite powder consists of the following components by weight percentage:

[0073]

[0074] Described metal powder is made up of the component of following percentage by weight:

[0075] Iron 93.5%

[0076] Silicon 3%

[0077] Chromium 3.5%

[0078] Described binding agent is made up of the component of following percentage by weight:

[0079]

[0080] According to the above weight percentages, they were mixed into a ball mill for mixing, and the frequency of the ball mill was set to 25 Hz and the time was 24 hr to prepare uniform ferrite slurry and metal powder slurry respectively.

[0081] The ferrite slurry and the metal powder slur...

experiment example 3

[0094] The ferrite slurry for tape casting is composed of the following components in weight percentage:

[0095] Ferrite powder 80%

[0096] Binder 20%

[0097] The metal powder slurry for tape casting is composed of the following components in weight percentage:

[0098] Metal powder 80%

[0099] Binder 20%

[0100] Wherein, the ferrite powder consists of the following components by weight percentage:

[0101]

[0102] Described metal powder is made up of the component of following percentage by weight:

[0103] Iron 91%

[0104] Silicon 5%

[0105] Chromium 4%

[0106] Described binding agent is made up of the component of following percentage by weight:

[0107]

[0108] According to the above weight percentages, they were mixed into a ball mill for mixing, and the frequency of the ball mill was set to 25 Hz and the time was 24 hr to prepare uniform ferrite slurry and metal powder slurry respectively.

[0109] The ferrite slurry and the metal powder slurry w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com