Electron injection method of metal-organic framework thin film

A metal-organic framework and electron injection technology, which is applied in organic light-emitting devices, organic light-emitting device manufacturing/processing, circuits, etc., can solve problems that have not been reported yet, and achieve low cost, good stability, and strong electron injection capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

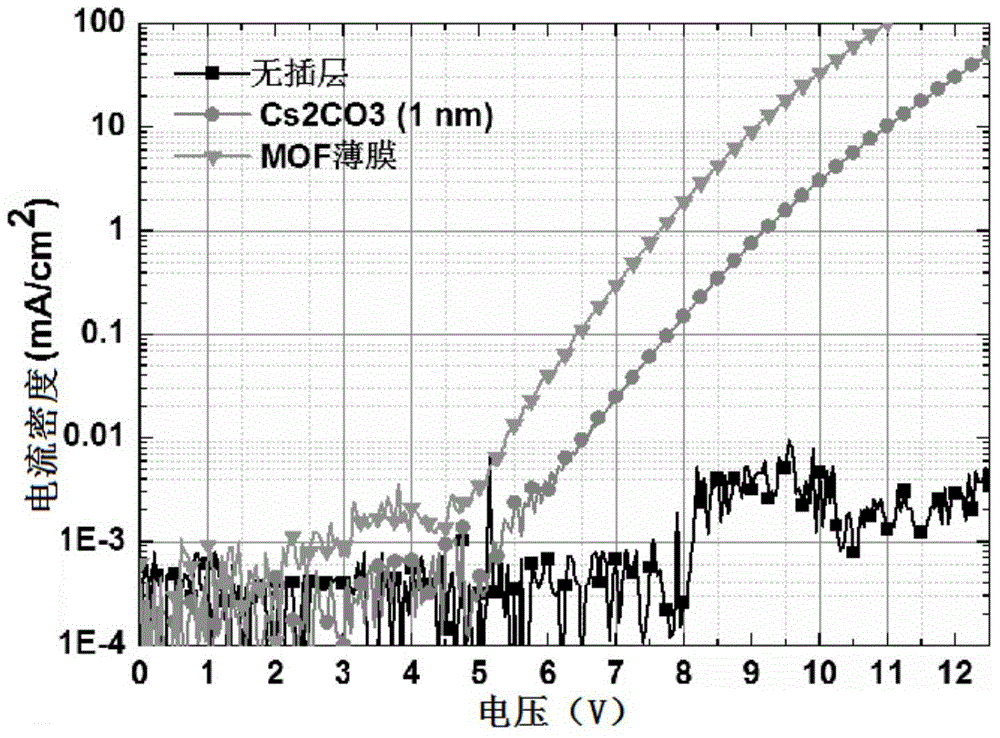

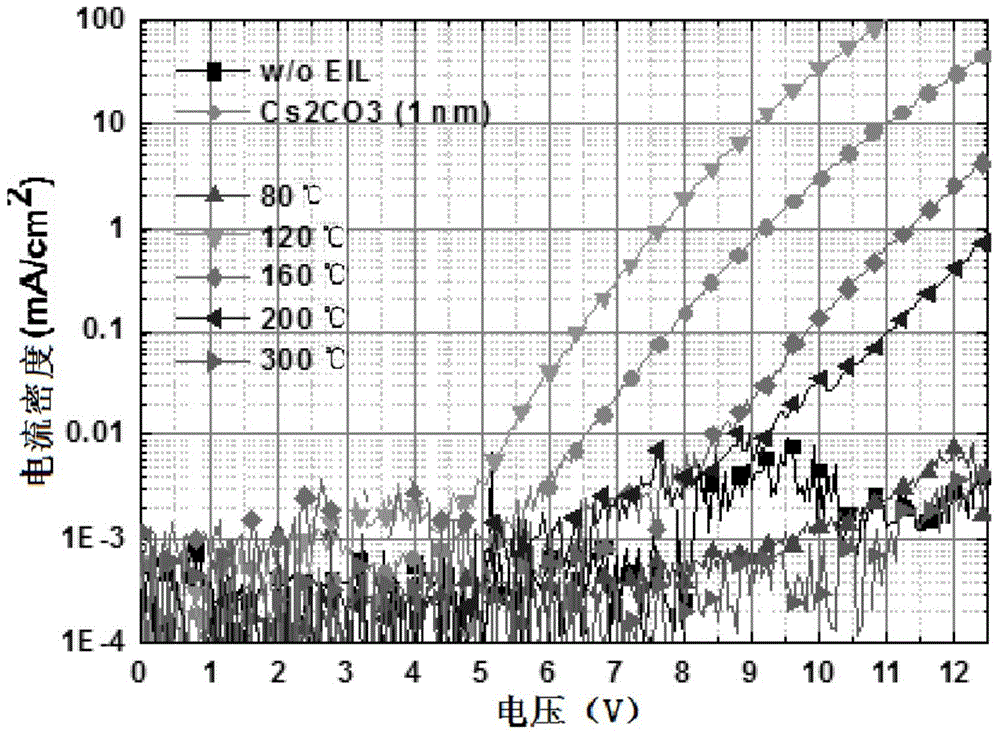

[0027] The technical method of the present invention is illustrated below with specific examples, but protection scope of the present invention is not limited thereto:

[0028] The electron injection method of the metal organic framework MOF thin film of the present embodiment, comprises the following steps:

[0029] Step 1, configure the formic acid solution that the volume ratio of formic acid and water is 1:9;

[0030] Step 2, take 60 mg of zinc oxide powder and add it to 1 ml of formic acid solution, because the formic acid content is low, the reaction product of zinc oxide and formic acid is completely dissolved in the formic acid solution;

[0031] Step 3, take 0.5ml of ammonia water and add it to the solution formed in step 2, first a white precipitate insoluble matter is formed, and finally the white precipitate is completely dissolved to form a clear and transparent MOF solution;

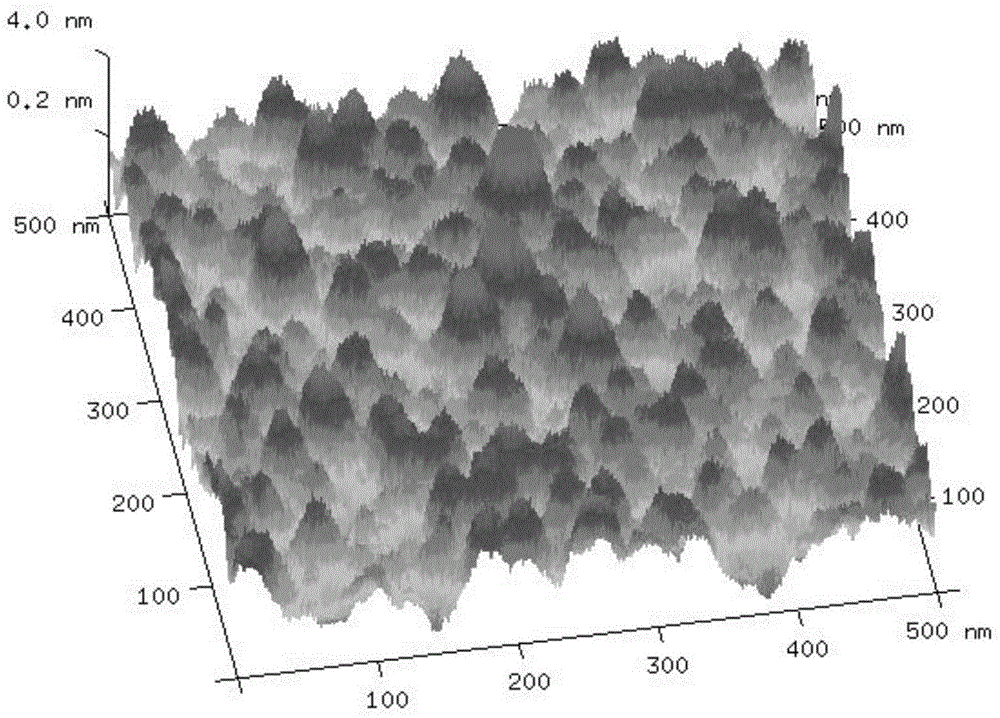

[0032] Step 4, take the MOF solution and add it dropwise on the clean ITO glass, spin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com