Transistor and transistor manufacturing method

A manufacturing method and transistor technology, applied in the direction of transistors, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of reduced electron concentration, reduced current flowing between drain-source electrodes, high plasma reactivity, etc., and achieve insulation destruction The effect of suppressing the reduction of current due to high voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

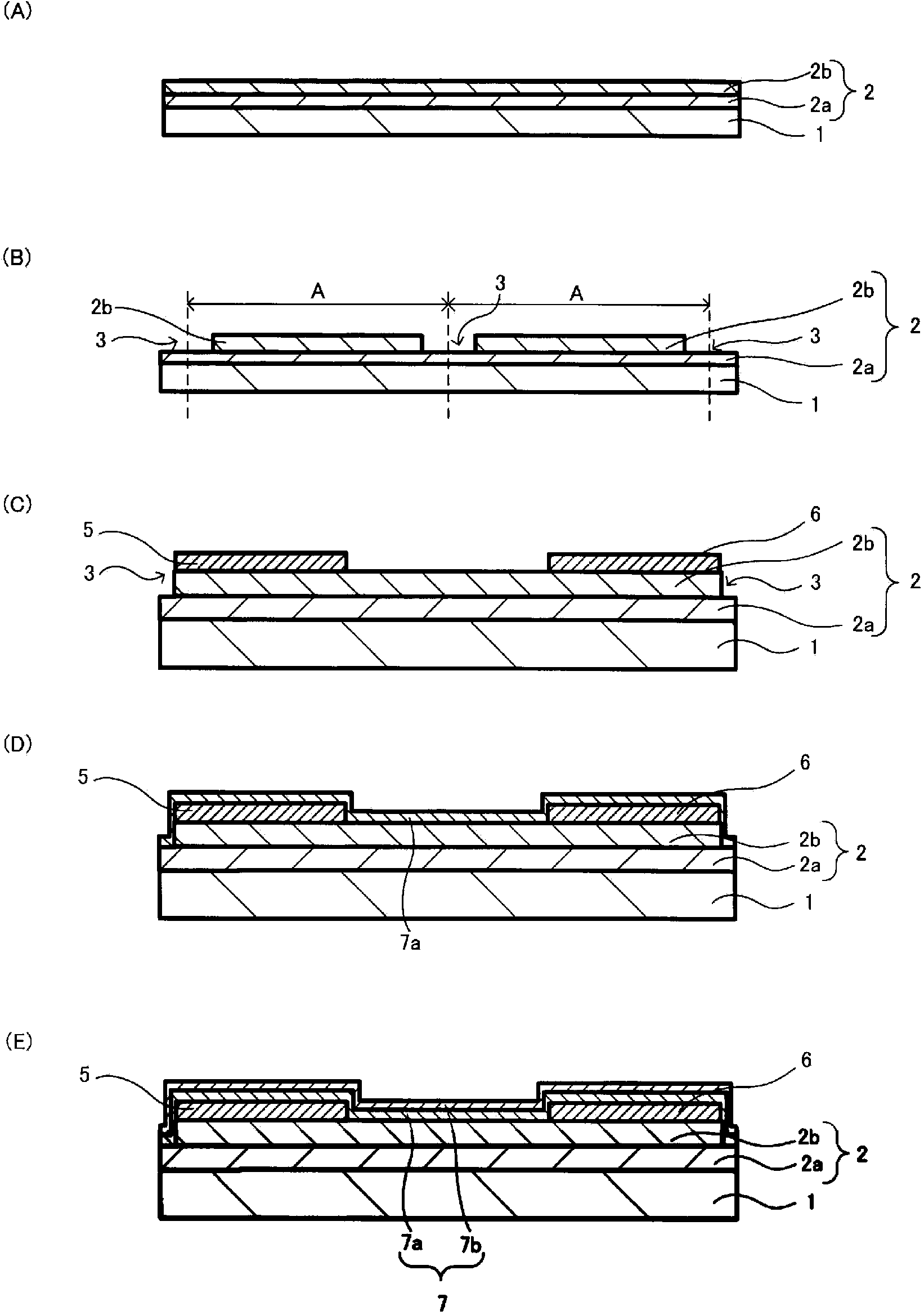

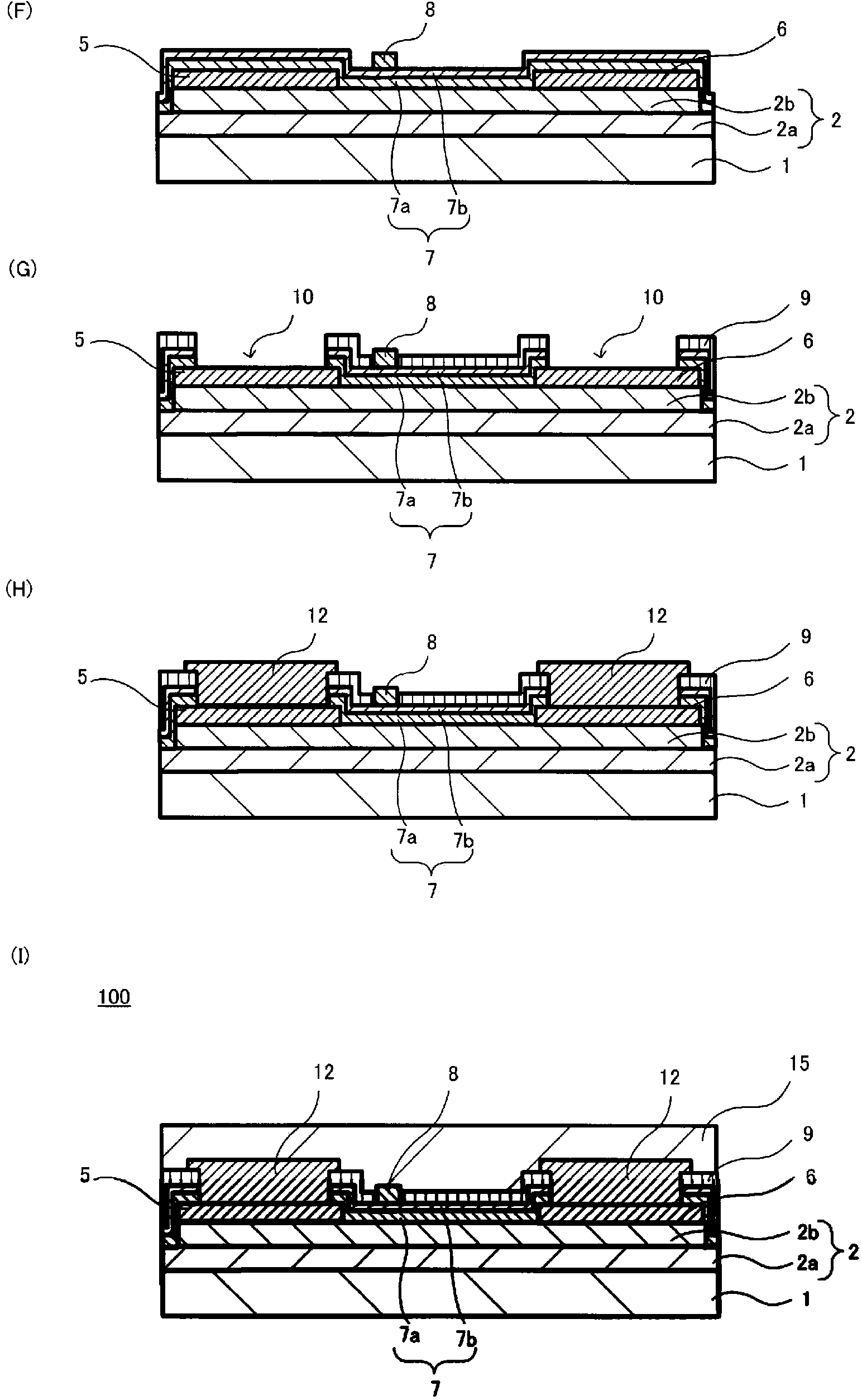

[0031] An example of a mode for implementing the present invention will be described below with reference to the drawings.

[0032] exist figure 2 (I) shows a cross-sectional view of the transistor 100 according to the embodiment of the present invention.

[0033] The transistor 100 includes a semiconductor layer 2 made of a gallium nitride layer 2 a and an aluminum gallium nitride layer 2 b on a substrate 1 made of gallium nitride, silicon, silicon carbide, or the like.

[0034] On the semiconductor layer 2, a source electrode 5 and a drain electrode 6 made of a material including titanium and aluminum are formed.

[0035] On the source electrode 5 and the drain electrode 6, a connection electrode 12 made of a material containing gold or the like is formed.

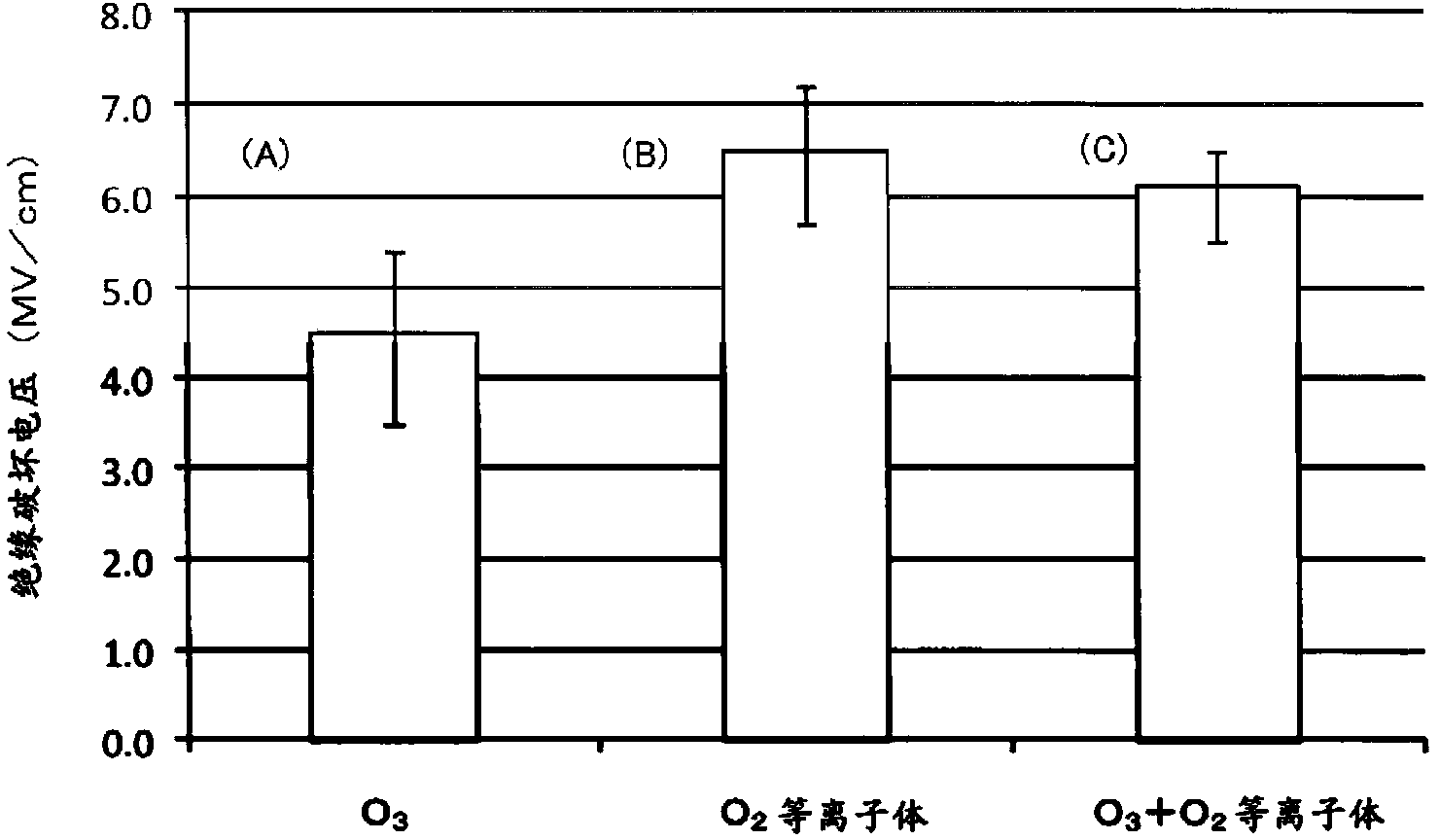

[0036] On a part of the semiconductor layer 2, a first gate insulating film 7a made of aluminum oxide or the like is formed. The first gate insulating film 7 a contains at least one of hydrogen atoms and carbon atoms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com