Dielectric composition and electronic component

A technology of electronic components and compositions, applied in the direction of electrical components, fixed capacitor dielectrics, niobium compounds, etc., can solve the problems of miniaturization requirements and other difficulties, and achieve high Q value, high relative permittivity, and high dielectric breakdown voltage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

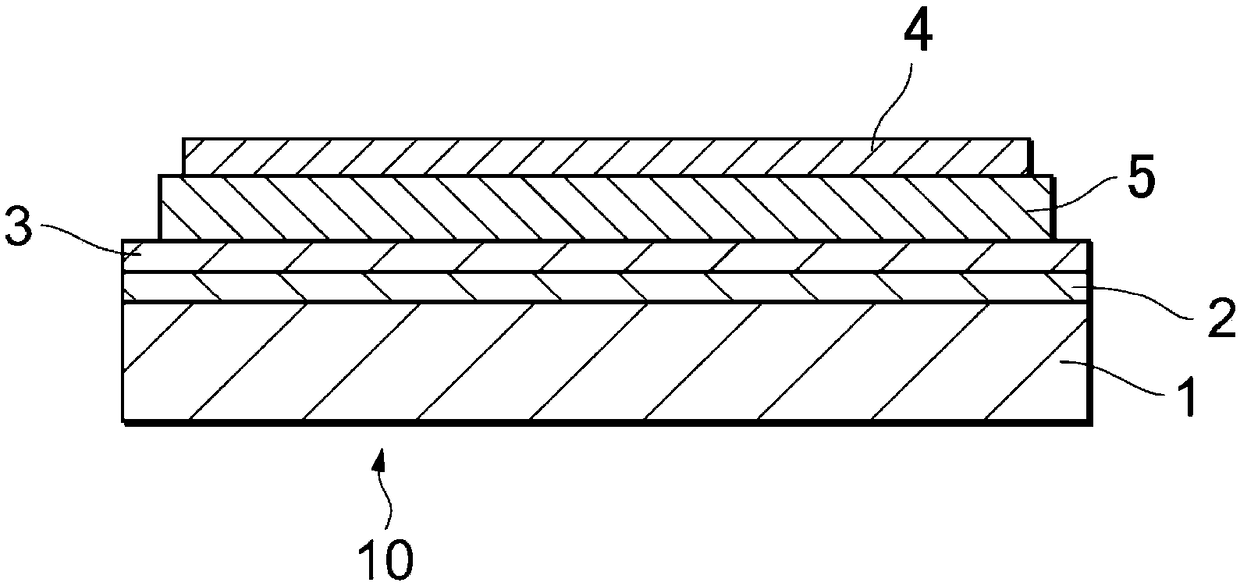

Image

Examples

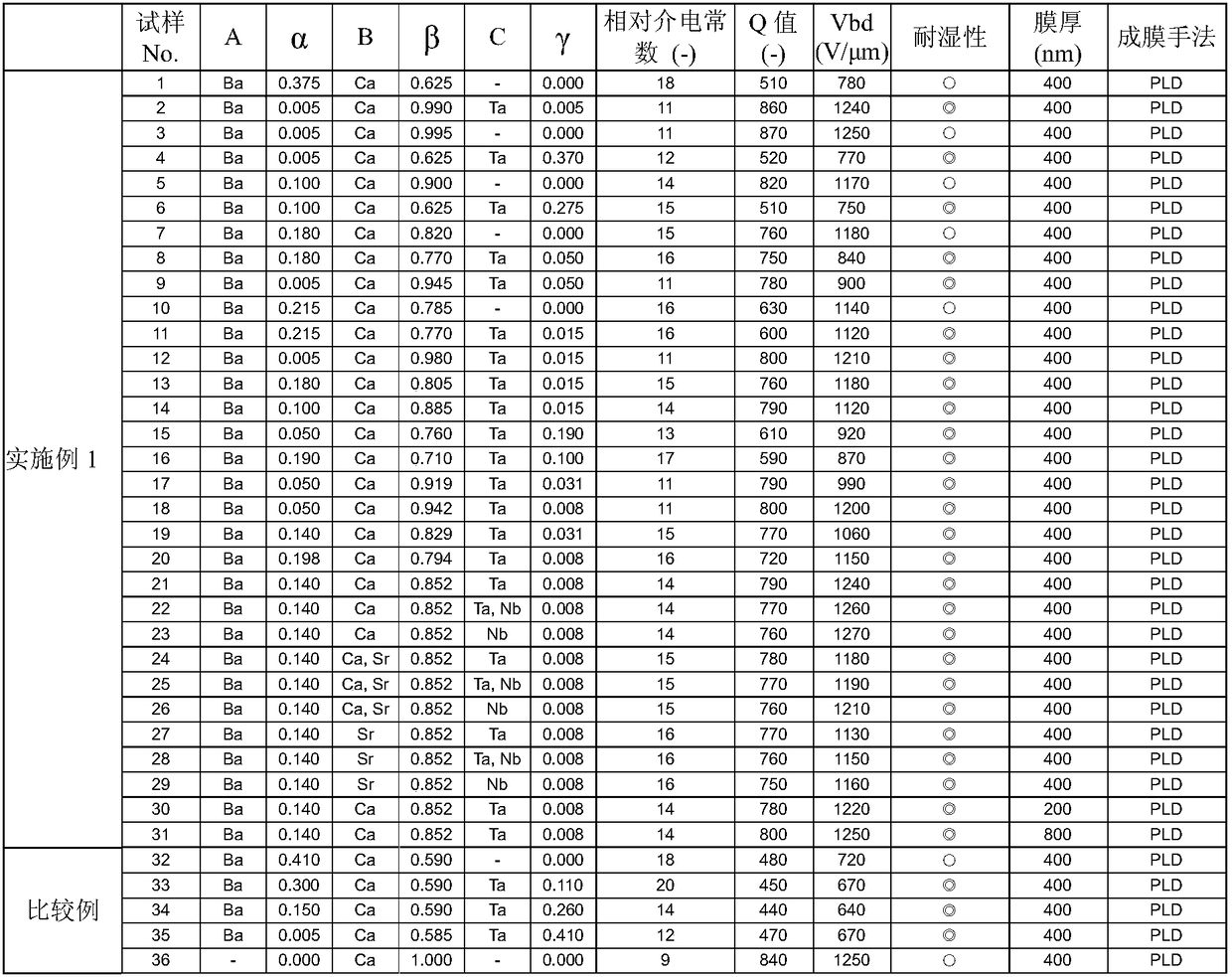

Embodiment 1

[0055]

[0056] First, a Ti thin film as an underlayer was formed on a Si surface with a thickness of 350 μm on SiO with a thickness of 6 μm by sputtering so as to have a thickness of 20 nm. 2 insulating film on the surface of a 10mm x 10mm square substrate.

[0057] Next, a lower electrode Pt thin film was formed to a thickness of 100 nm by sputtering on the Ti thin film formed as described above.

[0058] Heat treatment is performed on the formed Ti / Pt thin film under the conditions that the heating rate is 400° C. / min; the holding temperature is 700° C.; the temperature holding time is 0.5 hour; the atmosphere gas is oxygen atmosphere gas; and the pressure is normal pressure.

[0059] The method used in the formation of the dielectric film is the PLD method. Targets necessary for the formation of the dielectric film were prepared as follows.

[0060] First, BaCO was weighed in such a manner that it becomes the amount of Ba, Ca, Sr, Ta, and Nb of sample No. 1 to sample ...

Embodiment 2

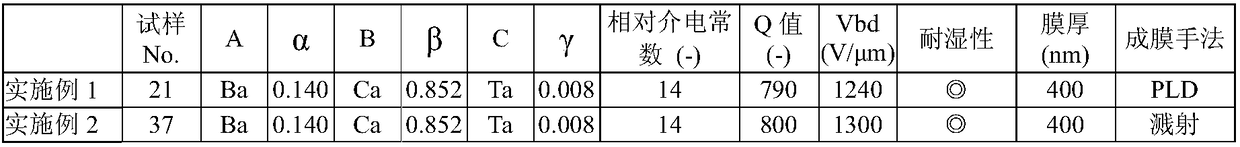

[0099] Samples were prepared in the same manner as in Sample No. 21 of Example 1 except that the dielectric film was formed by sputtering, and the same evaluations as in Example 1 were performed. The evaluation results are shown in Table 1.

[0100] [Table 2]

[0101]

[0102] Sample No.21, 37

[0103] From Table 2, it can be confirmed that using the dielectric film according to the present embodiment exhibits substantially the same characteristics if the composition is the same even if the method for producing the dielectric film is different. Industrial Utilization Possibility

[0104] As explained above, the present invention relates to a dielectric composition and an electronic component. The present invention provides a dielectric composition having a high relative permittivity, a high Q value, and a high dielectric breakdown voltage even in a high frequency (2 GHz) region, and An electronic component using the dielectric composition. Accordingly, miniaturization a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com