Semiconductor device

A technology of semiconductors and field effect transistors, applied in the field of semiconductor devices, can solve the problems of monolithic microwave integrated circuits, low thermal conductivity, difficult temperature management and atmospheric gas management, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

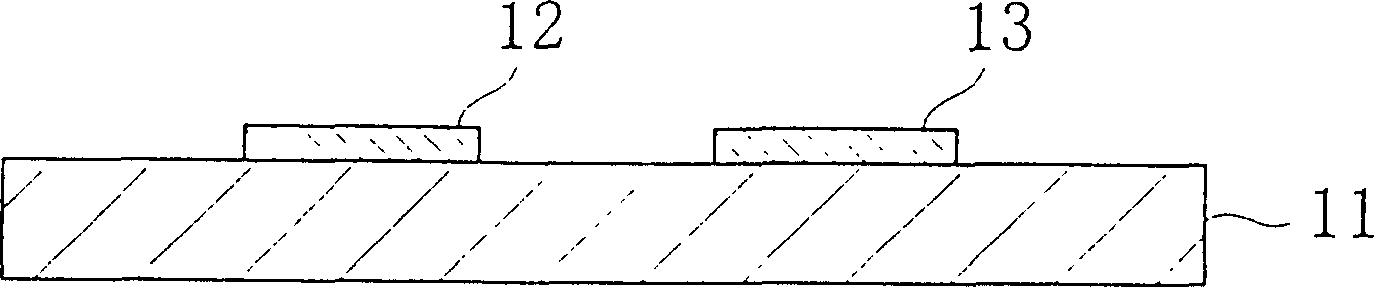

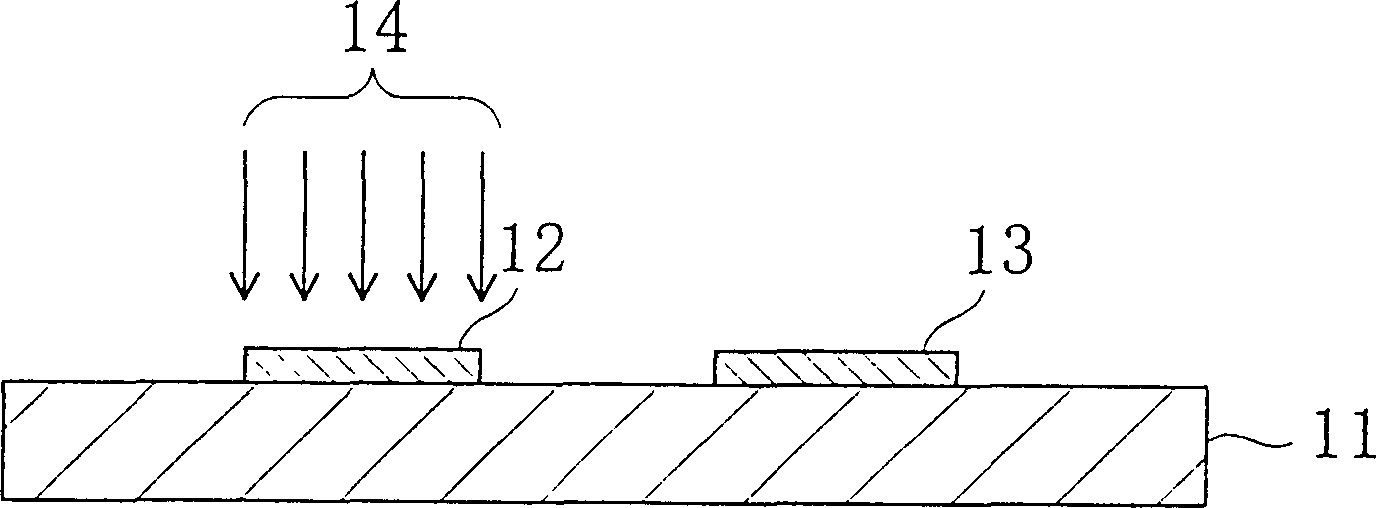

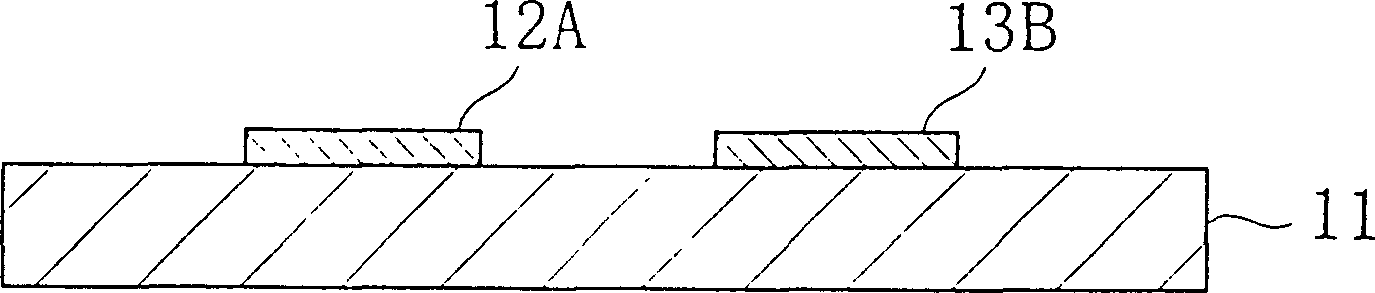

[0046] Next, a first embodiment of the present invention will be described with reference to the drawings.

[0047] 1( a ) to ( c ) are cross-sectional structural views showing the procedure of the method for forming an ohmic electrode according to the first embodiment of the present invention. First, as shown in FIG. 1( a ), a first metal film 12 and a second metal film 13 made of nickel (Ni) or the like are deposited on a substrate 11 made of silicon carbide, for example, by vapor deposition. In this state, the interface between the first metal film 12 and the substrate 11 and the interface between the second metal film 13 and the substrate 11 are not in ohmic contact, but are Schottky contacts in common.

[0048] Next, as shown in FIG. 1( b ), only the first metal film 12 of the substrate 11 is irradiated with the laser light 14 whose tip is narrowed from the upper surface of the substrate 11 . Therefore, as shown in FIG. 1( c), even if the substrate 11 is not heated, the ...

no. 2 example

[0054] Next, a second embodiment of the present invention will be described with reference to the drawings.

[0055] 2( a ) to ( c ) are cross-sectional structural diagrams showing the procedure of the ohmic electrode forming method according to the second embodiment of the present invention. First, as shown in FIG. 2( a ), a first metal film 22 and a second metal film 23 made of nickel or the like are deposited on a substrate 21 made of silicon carbide using a vapor deposition method. In this state, the first metal film 22 and the second metal film 23 are in Schottky contact with the substrate 21, respectively. Afterwards, using an electroplating method, a first electroplated metal film 24 is deposited on the first metal film 22 , and a second electroplated metal film 25 is deposited on the second metal film 23 .

[0056] Next, as shown in FIG. 2( b ), from the upper surface of the substrate 21 , only the first metal plating film 24 in the substrate 21 is irradiated with the...

no. 3 example

[0061] Next, a third embodiment of the present invention will be described with reference to the drawings.

[0062] 3( a ) to ( c ) are cross-sectional structural diagrams showing the procedure of the method for forming an ohmic electrode according to the third embodiment of the present invention. First, as shown in FIG. 3( a ), a first metal film 32 and a second metal film 33 made of nickel or the like are deposited on the surface of a substrate 31 made of silicon carbide. In this state, each interface between the first metal film 32 and the second metal film 33 and the substrate 11 is a Schottky contact in common.

[0063]Next, as shown in FIG. 3( b), the wavelength of irradiation of the substrate 31 from the surface side of the substrate 31 is a wavelength corresponding to the energy corresponding to the forbidden band (=Eg) of silicon carbide (=h·c / Eg) compared with laser light 34 having a sufficiently long wavelength. Thus, as shown in FIG. 3( c), even if the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com