Electrodeposition solution and method for producing conductor with insulating film using same

A technology of electrodeposition and solid components, applied in the direction of insulators, plastic/resin/wax insulators, electrophoretic plating, etc., can solve the problems of difficulty in forming thick films, easy foaming, and fast solvent volatilization, and reduce the amount of encapsulation , Inhibit foaming, improve the effect of insulation breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] [Preparation of dispersion liquid of polyimide-based resin particles]

[0031] Next, the polyimide resin varnish obtained above was further diluted with an organic solvent, and after adding a basic compound, it stirred and added water at room temperature. Thereby, the dispersion liquid of the polyimide-type resin particle whose median diameter is 50-400 nm is obtained.

[0032] [Preparation of dispersion of fluororesin particles]

[0033] After diluting commercially available fluororesin particles with water and then stirring, a dispersion of fluororesin particles having a median diameter of 50 to 500 nm was obtained.

[0034] [Preparation of Electrodeposition Solution]

[0035] An electrodeposition solution is obtained by mixing a dispersion of polyimide-based resin particles and a dispersion of fluororesin particles.

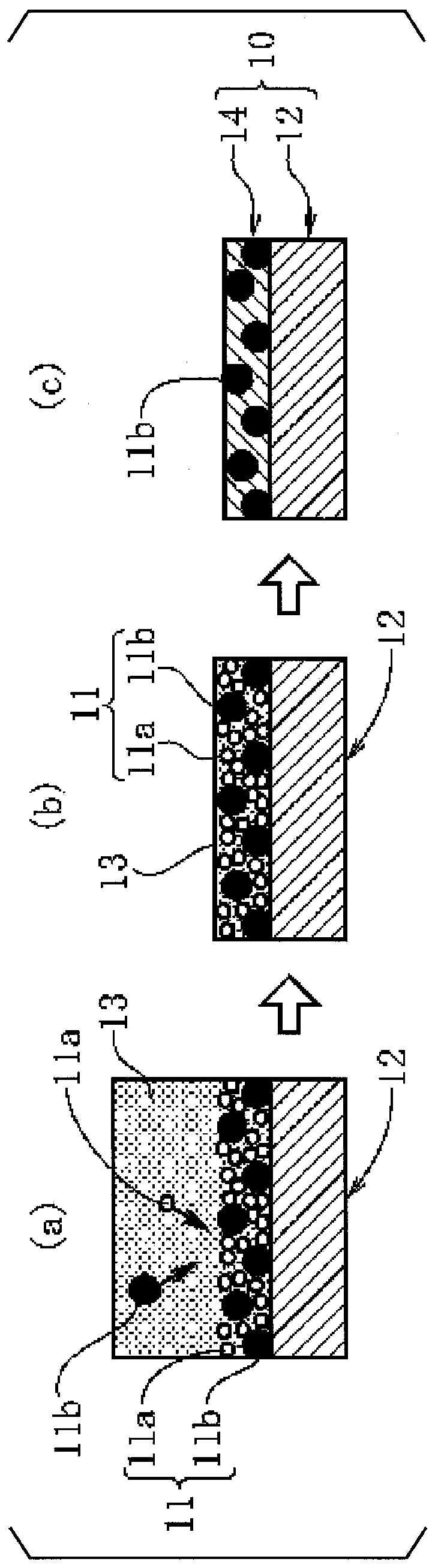

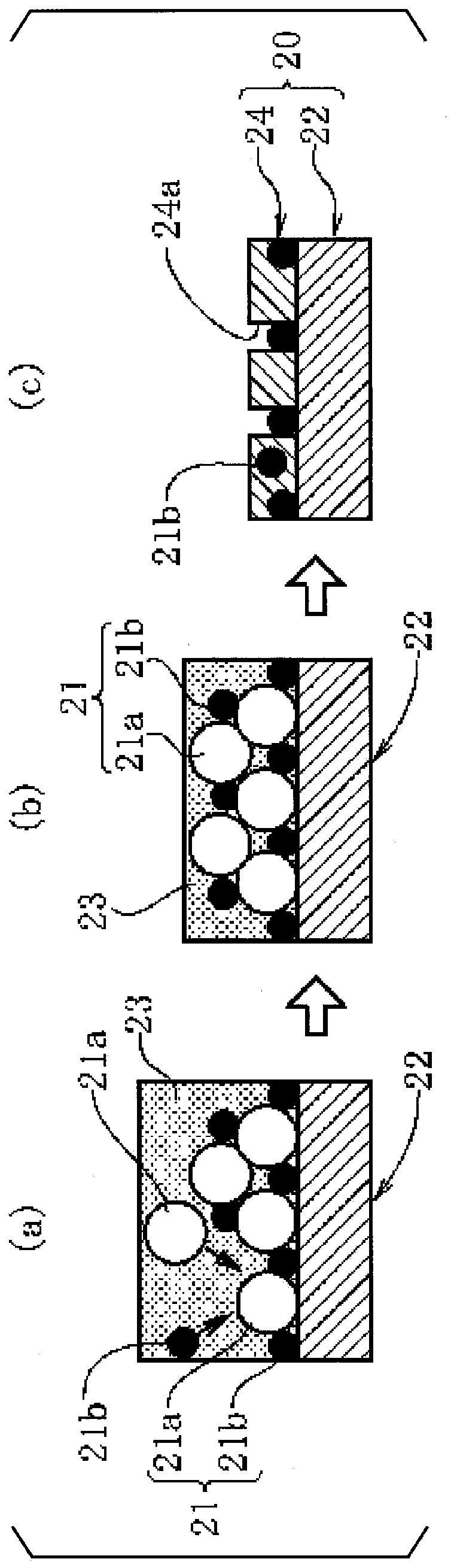

[0036] When using the above-mentioned electrodeposition solution to form an insulating coating on the surface of a conductor, it is preferable to us...

Embodiment

[0039] Next, examples of the present invention will be described in detail together with comparative examples.

[0040]

[0041] A method for producing an electrodeposition solution will be described.

[0042] [Synthesis of polyimide resin varnish]

[0043] First, 747 g of N-methyl-2-pyrrolidone (polar solvent) and 298 g (1.19 mol) of diphenylmethane were charged into a 2-liter four-necked flask equipped with a stirrer, a cooling tube, a nitrogen gas introduction tube, and a thermometer. - 4,4'-diisocyanate (MDI, isocyanate component) and 227 g (1.18 mol) of trimellitic anhydride (TMA, acid component) were heated up to 130°C. By reacting at this temperature for about 4 hours, a polymer (polyamideimide resin) having a number average molecular weight of 17,000 was obtained. Then, the polyamideimide resin synthesized above was diluted with N-methyl-2-pyrrolidone (polar solvent) so that the concentration of the polyamideimide resin (non-volatile component) became 20% by mass, ...

Embodiment 2~ Embodiment 10 and comparative example 1~ comparative example 8

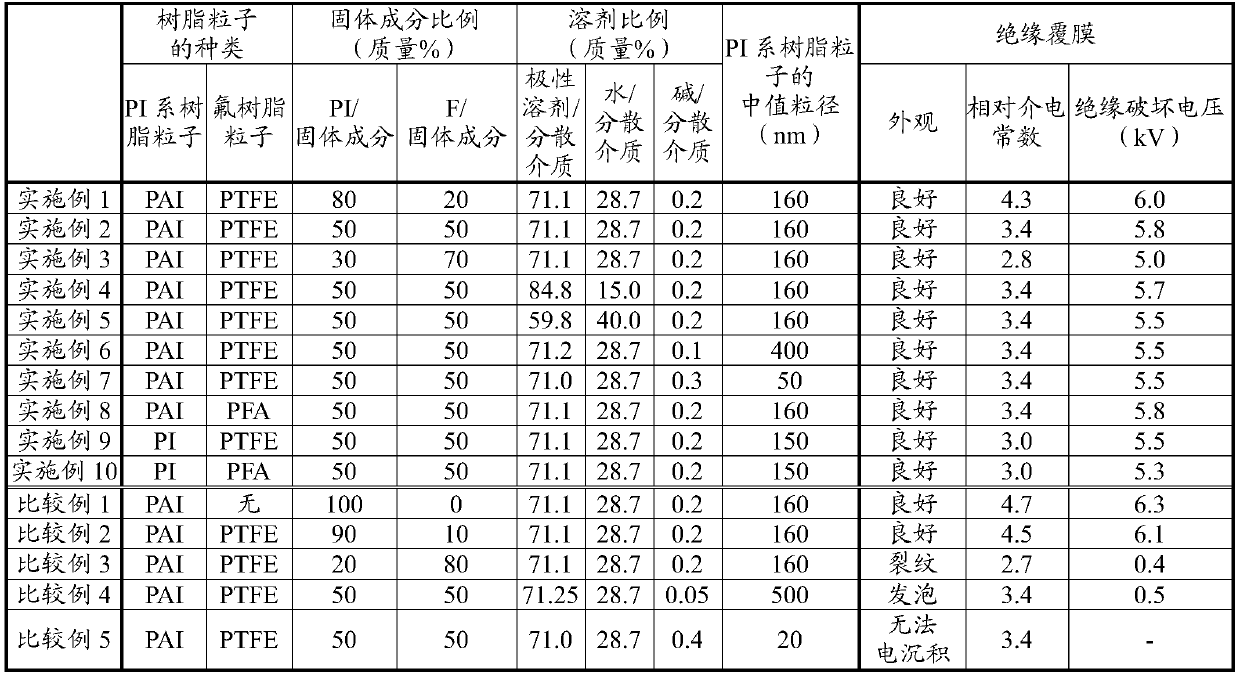

[0053] As shown in Table 1, the types of polyimide-based resin particles and fluorine-based resin particles, the content ratio of polyimide-based resin particles in the solid content, the content ratio of fluororesin particles in the solid content, and the dispersion ratio were changed. The content ratio of the polar solvent in the medium, the water content ratio in the dispersion medium, the alkali content ratio in the dispersion medium and the median diameter of the polyimide resin particles were prepared in the same manner as in Example 1. An electrodeposition solution, using the electrodeposition solution, a copper wire with an insulating coating was produced. These insulating-coated copper wires were used as Example 2-Example 10 and Comparative Example 1-Comparative Example 5.

[0054]

[0055]The appearances of the insulation coatings of the copper wires with insulation coatings of Examples 1 to 10 and Comparative Examples 1 to 5 were observed, and the relative permitt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com