All-weather efficient solar drying box and greenhouse

A solar energy, all-weather technology, applied in the field of all-weather solar high-efficiency greenhouses, can solve the problems of growers' loss, high energy consumption, and high cost, and achieve the effect of low investment in construction and transformation, good economic benefits, and low construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

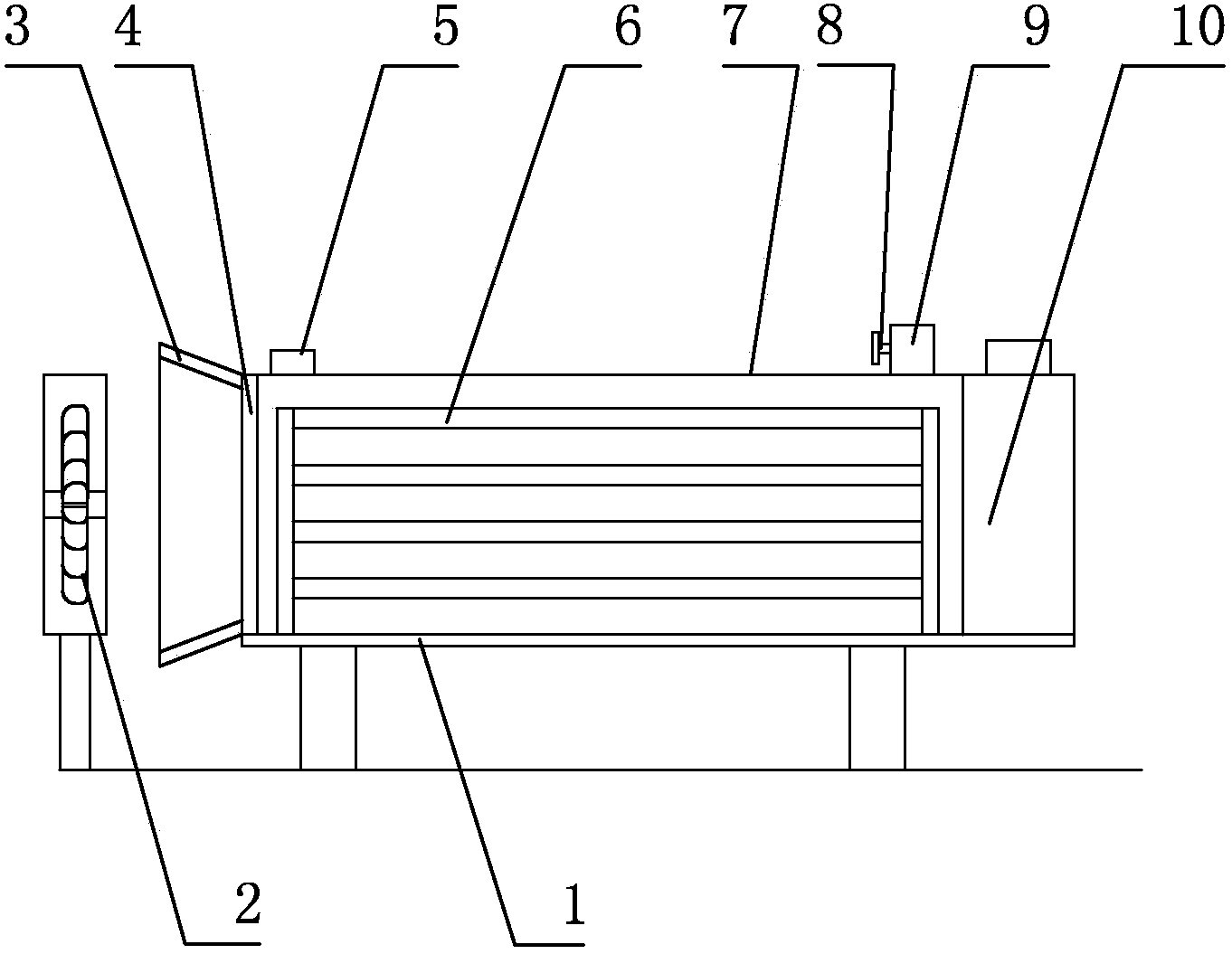

[0027] Such as figure 1 As shown, the all-weather solar high-efficiency drying box includes a tunnel-type housing 7 installed on the base 1, a drying rack 6 is provided inside the housing 7, and a first air vent 5 is provided above the front of the housing 7. A front door 4 is installed at its front port, and the front door 4 can be a lifting type or a side opening type, and can be opened and closed by manual or motor drive. Housing 7 front port portion is provided with guide port 3, and guide port 3 is the trumpet shape of outward expansion from inside to outside, and guide port 3 front side is provided with fan 2, also can adopt air blower, by the guiding effect of guide port 3, fan Most of the generated wind power enters the casing 7 to expand the air intake area, and at the same time, the fan power can be selected more flexibly.

[0028] The side wall of the housing 7 is covered with an insulating layer, and the insulating material is rock wool, foam glass, phenolic, poly...

Embodiment 2

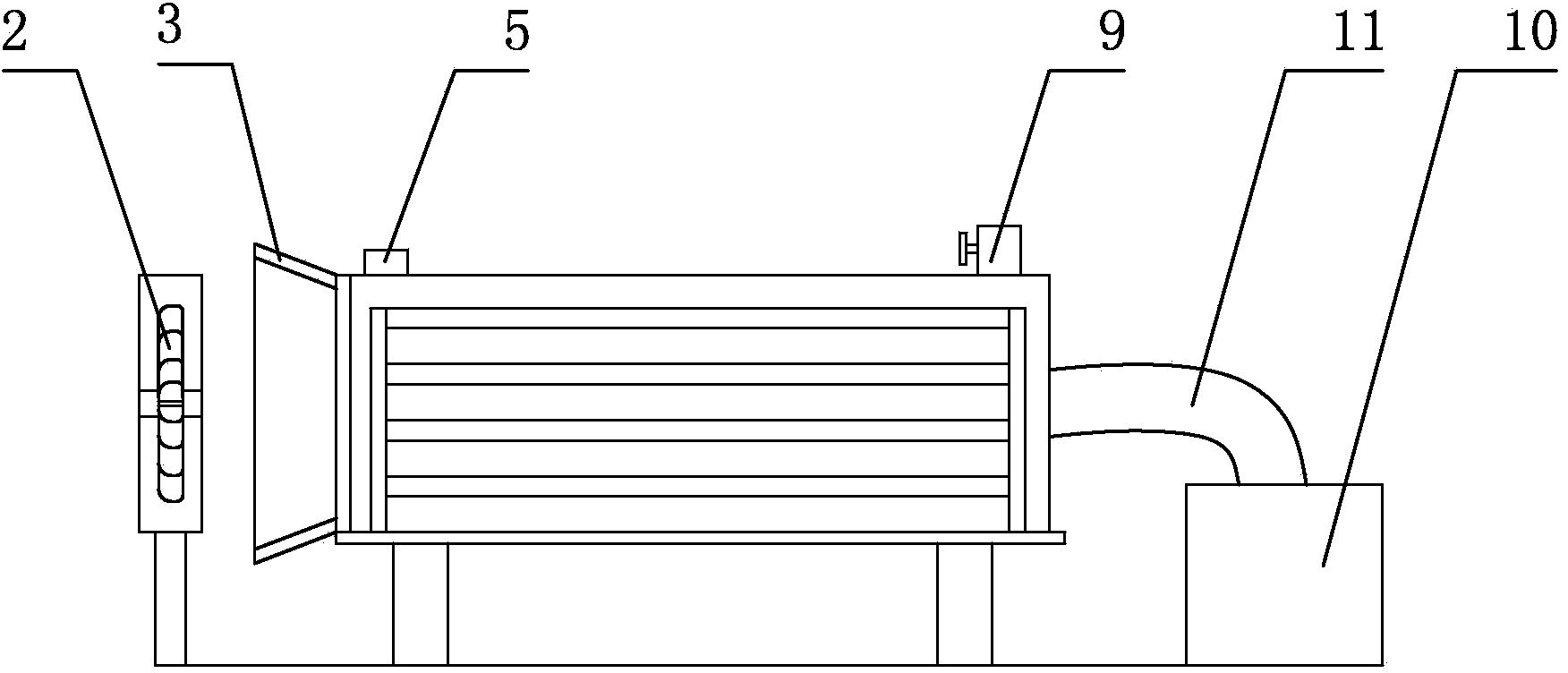

[0030] Such as figure 2 As shown, the air source heat pump 10 is connected to the rear end of the casing 7 through the ventilation pipe 11, so that the installation position of the air source heat pump 10 is more flexible, and the rest is the same as that of Embodiment 1.

Embodiment 3

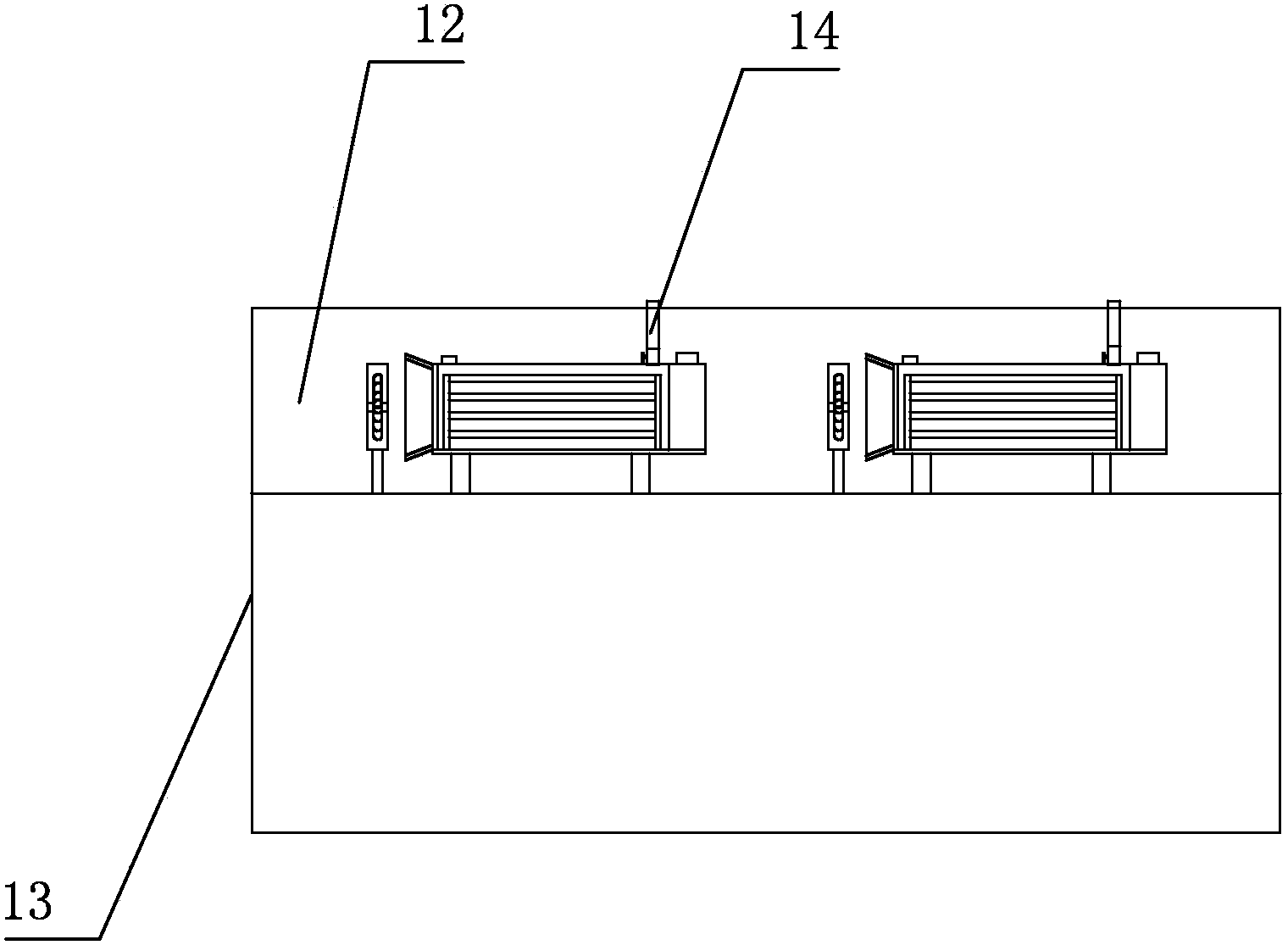

[0032] Such as Figure 3-4 As shown, the all-weather solar high-efficiency greenhouse includes a shed body 13, and a drying chamber 6 is arranged on the upper part of the shed body 13. According to the actual length of the drying chamber 6, multiple groups of all-weather solar energy high-efficiency drying boxes can be arranged vertically, such as a set of or two groups. The second vent 9 of the drying box is connected to one end of the exhaust pipe 14 , and the other end of the exhaust pipe 14 extends to the outside of the shed body 13 . Absorb sunlight through the shed body 13, so that the temperature in the drying room meets the drying requirements. It can reach 60-70°C in sunny summer and 30-40°C in winter, which fully meets the drying needs of fungi and other plants. .

[0033] An automatic control system is also provided in the greenhouse, and by monitoring the temperature and humidity in the drying chamber 12, the opening and closing of the fan 2, the front door 4, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com