Method for preparing load type nanogold catalyst

A nano-gold and catalyst technology, which is applied in the field of preparation of supported nano-gold catalysts, can solve problems such as single gold anchor point properties, catalyst catalytic activity, catalyst stability constraints, etc., and achieve good catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of supported nanometer gold catalyst comprises the steps:

[0025] step one

[0026] at 60 o Under the condition of C, take 19% polyoxypropylene polyoxyethylene copolymer solution and dissolve it in deionized water to form cloudy solution A;

[0027] step two

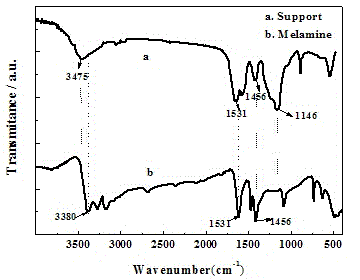

[0028] Prepare 15% formaldehyde into a 37 wt.% formaldehyde aqueous solution, then mix it with deionized water to obtain a cloudy solution B, then adjust the pH value of solution B to 8.7 with sodium hydroxide aqueous solution, and then add 11% Melamine and 7% thiourea, at 60 o C was stirred for 2 hours to obtain solution C;

[0029] step three

[0030] Pour solution A into solution C and stir for 2.5 hours to obtain solution D. During the stirring of solution D, dissolve 40% water glass in deionized water and stir at room temperature for about 30 minutes to obtain solution E. In solution D Quickly pour 8% glacial acetic acid, under vigorous stirring, immediately pour solution E into ...

Embodiment 2

[0034] The preparation method of supported nanometer gold catalyst is characterized in that comprising the steps:

[0035] step one

[0036] at 70 o Under the condition of C, take 23% polyoxypropylene polyoxyethylene copolymer solution and dissolve it in deionized water to form cloudy solution A;

[0037] step two

[0038] Prepare 17% formaldehyde into a formaldehyde aqueous solution with a concentration of 37 wt.%, then mix it with deionized water to obtain a cloudy solution B, then adjust the pH value of solution B to 8.5-9.0 with aqueous sodium hydroxide solution, and then add 9 % of melamine and 6% of thiourea, at 50 o C was stirred for 3 hours to obtain solution C;

[0039] step three

[0040] Pour solution A into solution C and stir for 3 hours to obtain solution D. During the stirring of solution D, dissolve 38% water glass in deionized water and stir at room temperature for about 35 minutes to obtain solution E. In solution D Quickly pour 7% glacial acetic acid, ...

Embodiment 3

[0044] The preparation method of supported nanometer gold catalyst is characterized in that comprising the steps:

[0045] step one

[0046] at 50 o Under the condition of C, take 15% polyoxypropylene polyoxyethylene copolymer solution and dissolve it in deionized water to form cloudy solution A;

[0047] step two

[0048] Prepare 13% formaldehyde into a 37 wt.% formaldehyde aqueous solution, mix it with deionized water to obtain a cloudy solution B, adjust the pH value of solution B to 8.5-9.0 with sodium hydroxide aqueous solution, and then add 13 % of melamine and 8% of thiourea, at 70 o C was stirred for 1 hour to obtain solution C;

[0049] step three

[0050] Pour solution A into solution C and stir for 2 hours to obtain solution D. During the stirring of solution D, dissolve 42% water glass in deionized water and stir at room temperature for about 25 minutes to obtain solution E. In solution D Quickly pour 9% glacial acetic acid, under vigorous stirring, immediately...

PUM

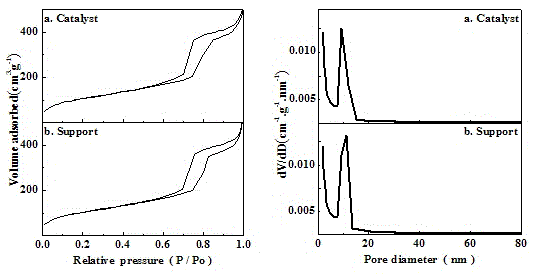

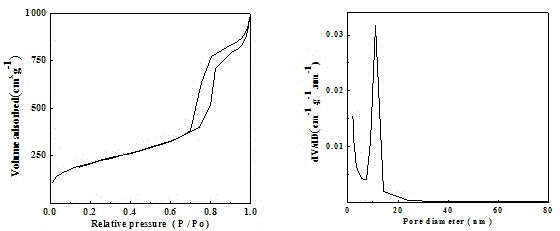

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com