Rapid and controllable preparation method of ssz-13 zeolite and h-ssz-13 zeolite and methanol-to-olefins catalyst

A zeolite, fast technology, applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high energy consumption in SSZ-13 zeolite production, hindering industrial application, poor molecular diffusion ability, etc. Controllable particle size, high selectivity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment provides a method for preparing a methanol-to-olefins catalyst, which comprises the following steps:

[0053] Weigh 25.0g of template agent TMAdaOH (25wt%) and 0.9g of sodium hydroxide, add 89.3g of deionized water, stir and mix evenly;

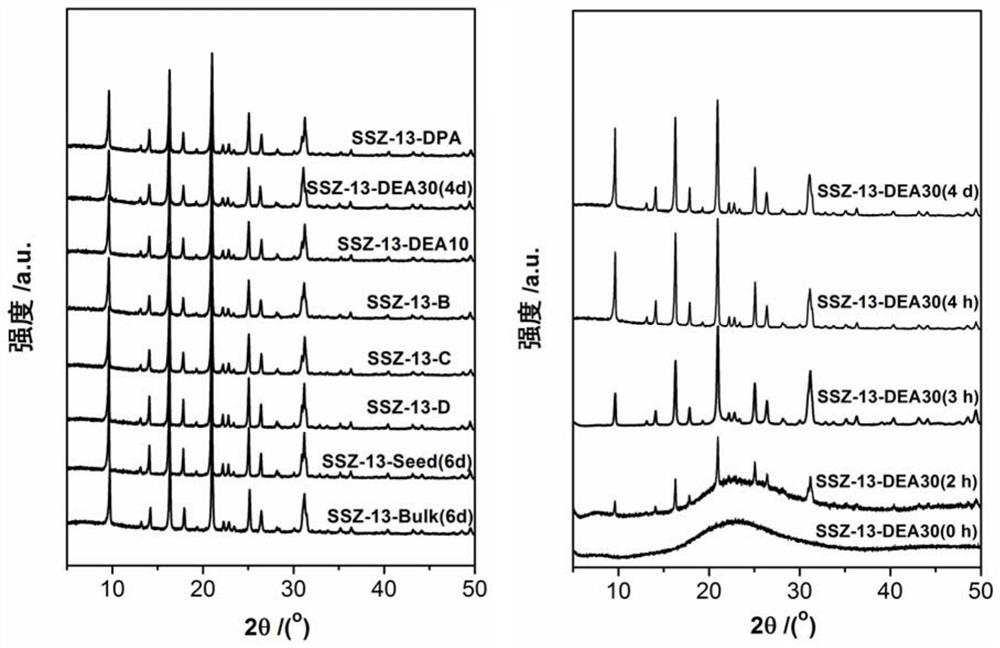

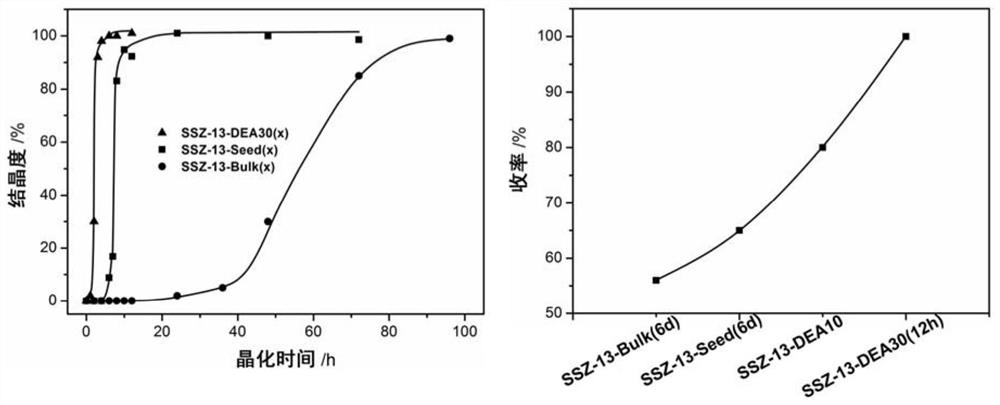

[0054] Add 0.37g of aluminum hydroxide to the above solution at one time, stir vigorously for 10 minutes; then slowly add 9g of silicon source silica, stir for 30 minutes, add 0.18g of seed crystals, and continue vigorously stirring at about 30°C for 2 hours for aging ;

[0055] The obtained gel was transferred to several crystallization kettles in equal parts, and statically crystallized, the temperature was set at 160°C, and the crystallization time was 0 hour, 2 hours, 4 hours, 6 hours, 7 hours, 8 hours, 10 hours, 12 hours, 24 hours, 48 hours, 72 hours, 6 days; after the crystallization is completed, the crystallization kettle is quenched with water to room temperature, the solid product in it is centrifuged and w...

Embodiment 2

[0059] This embodiment provides a method for preparing a methanol-to-olefins catalyst, which comprises the following steps:

[0060] Weigh 130.2g of template agent TMAdaOH (25wt%) and 25.6g of sodium hydroxide, add 478.5g of deionized water, place in a 30°C water bath, stir and mix evenly;

[0061] Add 5.0g of aluminum hydroxide to the above solution and stir vigorously for 10 minutes;

[0062] Add 96g of silicon source D silicon at one time, stir vigorously for 30 minutes, add 1.9g of small crystal seeds, and continue to stir and age at about 30°C for 2 hours to obtain a gel;

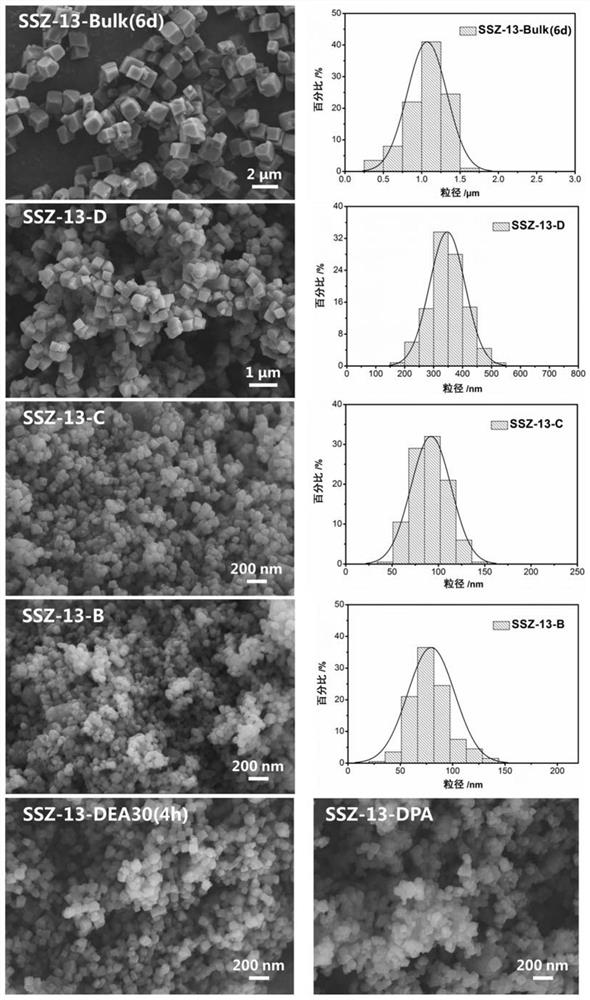

[0063] The obtained gel was transferred to a crystallization kettle, dynamic crystallization was performed at 20 rpm, the temperature was set at 160°C, and the crystallization time was 4 days; after the crystallization was completed, the kettle was taken out and quenched with water to room temperature, centrifuged and washed with water until neutral. The obtained sample was dried in an oven at 120°C, ...

Embodiment 3

[0067] This embodiment provides a method for preparing a methanol-to-olefins catalyst, which comprises the following steps:

[0068] Weigh 130.2g of template agent TMAdaOH (25wt%) and 25.6g of sodium hydroxide, add 478.5g of deionized water, place in a 30°C water bath, stir and mix evenly;

[0069] Add 5.0g of aluminum hydroxide to the above solution and stir vigorously for 10 minutes;

[0070] Add 96 g of solid silicon source C silicon at one time, stir vigorously for 30 minutes, add 1.9 g of small crystal seeds, and continue to stir and age at about 30 ° C for 2 hours to obtain a gel;

[0071] Transfer the obtained gel to a crystallization kettle, conduct dynamic crystallization at 20 rpm, set the crystallization temperature at 160°C, and crystallize for 4 days; after the specified crystallization time is reached, take out the crystallization kettle and quench it with water to room temperature , centrifuged and washed with water until neutral, the obtained sample was dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com