Preparation method of pure water cracking semiconductor catalyst for realizing visible light response by bimetal ion co-doped strontium titanate

A technology of metal ions and photocatalysts, which is applied in the field of synthesis of photocatalytic nanomaterials, can solve the problems of low photocatalytic water splitting activity and loss of activity, achieve good catalytic activity and stability, mild and safe reaction conditions, and easy preparation process operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] an Al 3+ , Cr 3+ The preparation method of the ion co-doped strontium titanate semiconductor catalyst comprises the following steps:

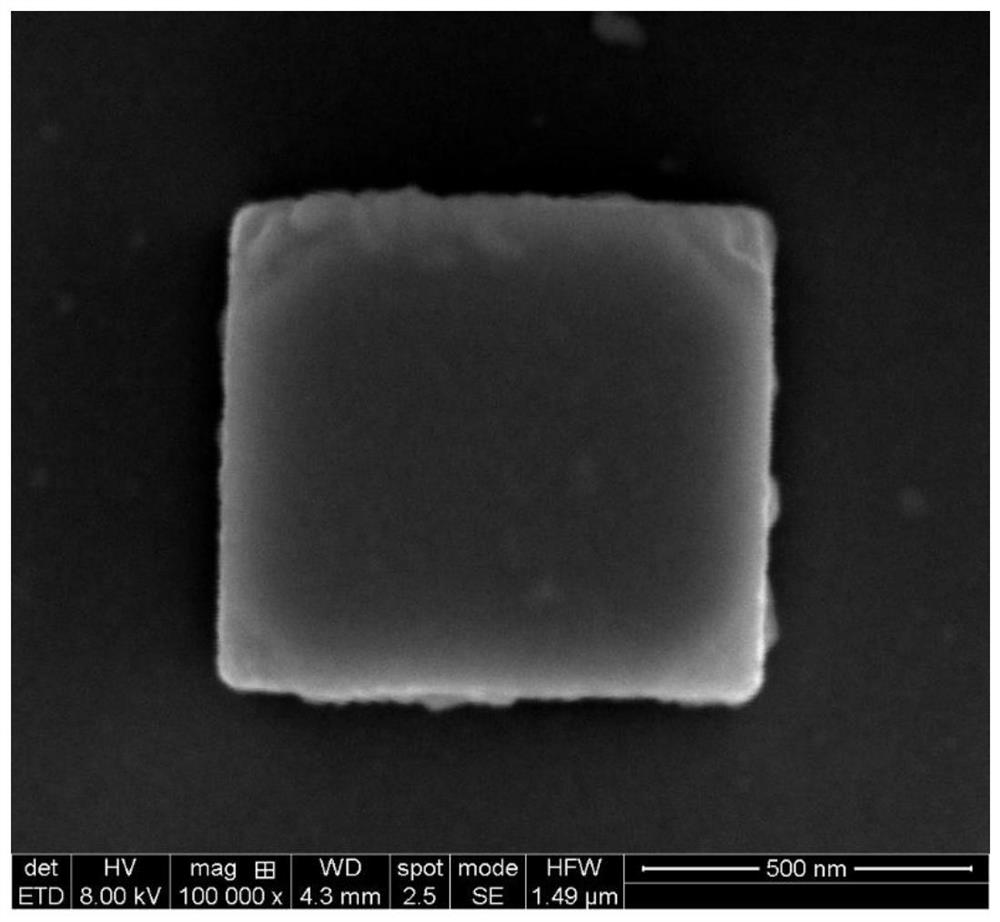

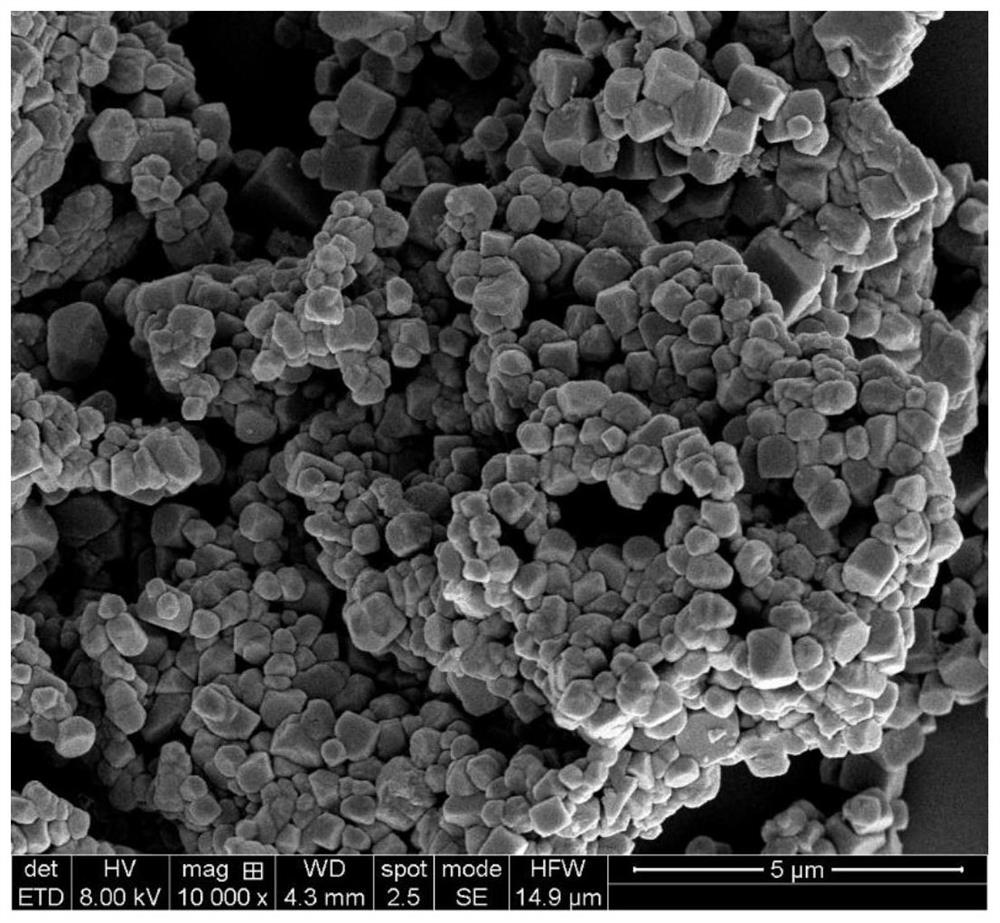

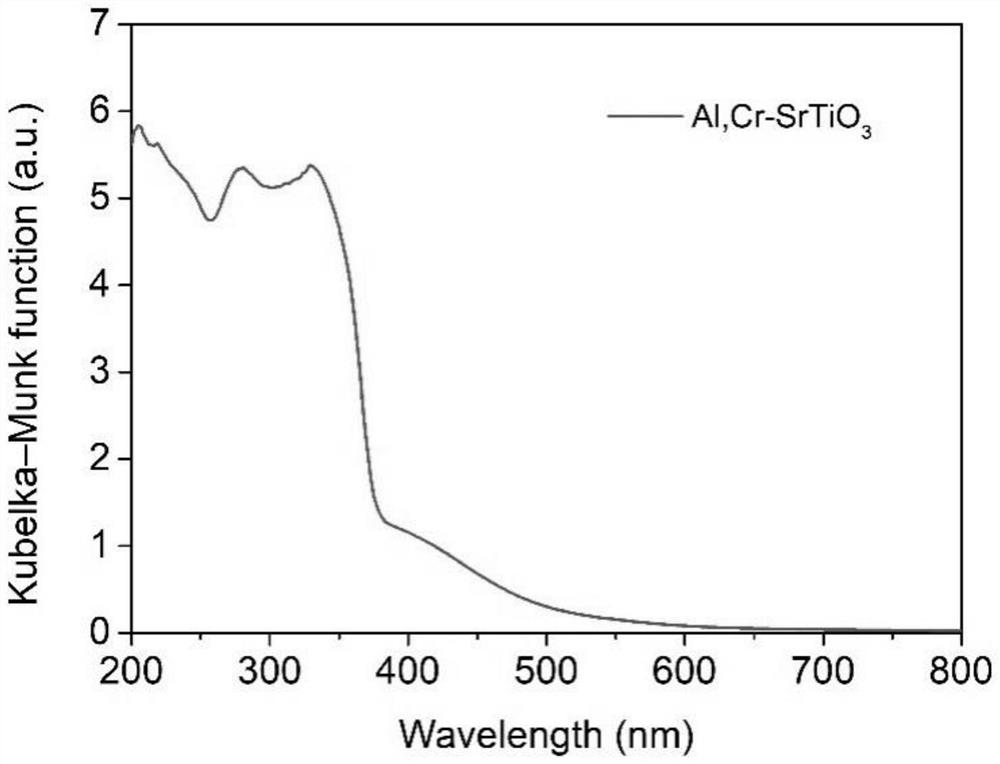

[0033] Weigh 0.08mol of strontium nitrate, 20ml of ethylene glycol and 6ml of isopropyl titanate respectively, mix them in a beaker, heat and stir at 80°C for 100min, continue to add 0.0008mol of aluminum nitrate and 0.0008mol of chromium nitrate, and transfer the mixture They were placed in an oil bath and heated at 120 °C for 600 min to obtain a transparent resin gel, and then heat-treated in air at 450 °C for 6 hours to obtain double metal ion co-doped SrTiO 3 The precursor, the precursor is generally black. Double metal ion co-doped SrTiO obtained after the precursor heat treatment at 900℃ 3 , again with excess SrCl 2 After uniform grinding, it was kept in a muffle furnace at 1000°C for 10 hours. After taking it out, it was filtered and washed with a large amount of deionized water, and then the material was dried in a drying bo...

Embodiment 2

[0039] a Ga 3+ , Rh 3+ The preparation method of the ion co-doped strontium titanate semiconductor catalyst comprises the following steps:

[0040] Weigh 0.15 mol of strontium nitrate, 25 ml of ethylene glycol and 10 ml of isopropyl titanate, respectively, mix them in a beaker, heat and stir at 90°C for 100 min, continue to add 0.0015 mol of gallium nitrate and 0.0015 mol of rhodium nitrate, and transfer the mixture. Placed in an oil bath and heated at 150 °C for 700 min to obtain a transparent resin gel, and then heat-treated at 550 °C in air for 6 hours to obtain double metal ion co-doped SrTiO 3 The precursor, the precursor is generally black. Double metal ion co-doped SrTiO obtained after the precursor heat treatment at 900℃ 3 , again with excess SrCl 2 After uniform grinding, it was kept in a muffle furnace at 1100°C for 12 hours. After taking out, it was filtered and washed with a large amount of deionized water, and then the material was dried in a drying box at 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com