A kind of diene selective hydrogenation catalyst and its preparation method and application

A hydrogenation catalyst and selective technology, which is applied in the field of diene selective hydrogenation catalyst and its preparation, can solve the problems of low conversion rate of hydrogenation catalyst, low selectivity of hydrogenation catalyst, and unsatisfactory effect, etc. Achieve the effects of good product selective hydrogenation, improve the problem of agglomeration and loss, and improve the problem of selectivity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

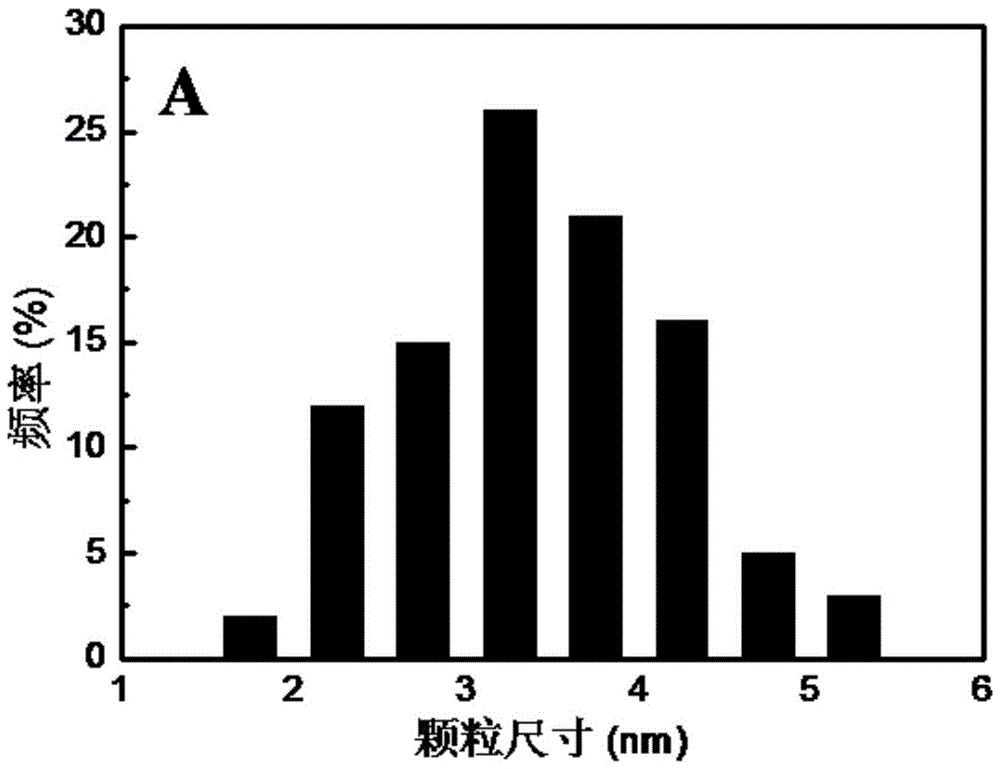

[0033] This example provides a catalyst for the selective hydrogenation of diolefins. Based on the weight of the catalyst carrier, the content of the active component palladium is 0.3 wt%, which is designated as catalyst A.

[0034] The catalyst is prepared by the following steps:

[0035] Dissolve 3.6 g of CTAB and 3.0 g of NaOH in 50 ml of deionized water, stir until completely dissolved, add 1.3 g of 2-methyl-1H-imidazole-4,5-dicarboxylic acid, and add 1.2 g of Zn( NO 3 ) 2 ·6H 2 O, obtain mixed reaction solution;

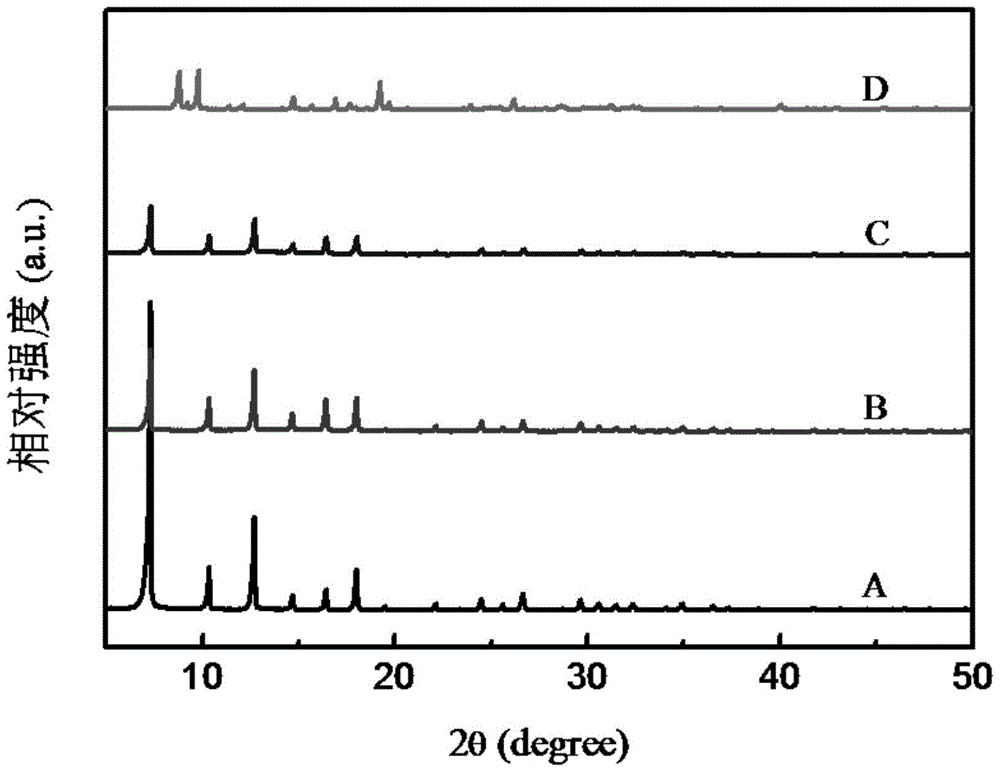

[0036] Pour the reaction solution into a 100 ml polytetrafluoroethylene reactor, crystallize at 140°C for 24 hours, cool naturally to room temperature after the reaction, separate the solid product by suction filtration, wash with deionized water, extract CTAB with absolute ethanol, and then The product was separated by centrifugation and dried at 100°C for 12 hours to make a catalyst carrier FZIF-8. Its XRD spectrum is as follows: figure 1 shown;

[0037]...

Embodiment 2

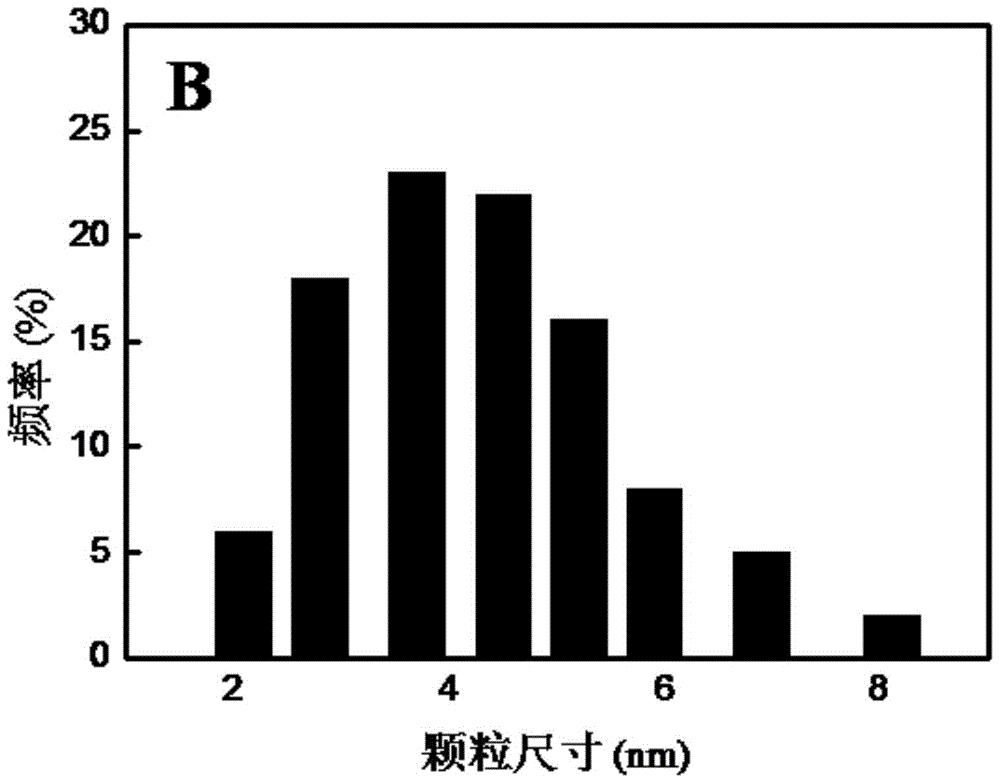

[0039] This example provides a catalyst for the selective hydrogenation of diolefins. Based on the weight of the catalyst carrier, the content of the active component palladium is 0.3 wt%, which is designated as catalyst B. The particle size distribution of palladium is shown in Figure 2B shown.

[0040] The preparation method is the same as in Example 1, except that the amount of CTAB is changed to 2.6 grams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com