Conjugated linoleic acid isomer biological enrichment method

A conjugated linoleic acid and bio-enrichment technology, applied in the field of biomedicine, can solve problems such as limitations, and achieve the effects of reducing inhibitory effects and enhancing health care functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

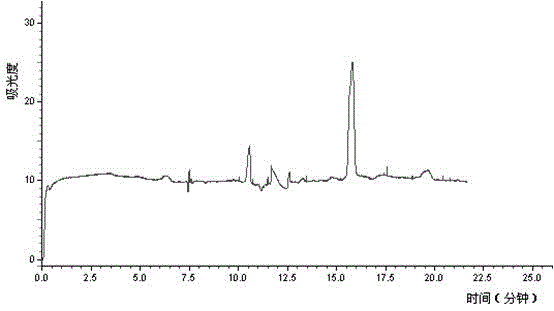

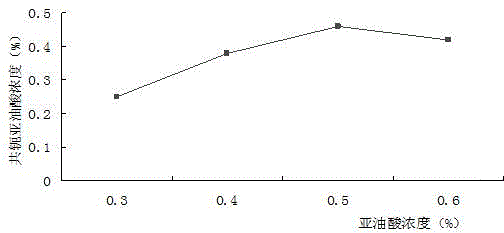

[0020] After soaking 1 part of low-temperature defatted soybeans with 4 parts of water overnight, coarsely grind and then finely grind 1 time with a refiner, and then process 2 times with a colloid mill to obtain a mixed emulsion. After boiling, adjust the protein content therein to The mass percentage is 8% to obtain the basal medium. Add 1% fructo-oligosaccharides by mass to the basic medium, and pasteurize to obtain a bio-enriched medium. Insert 5% Lactobacillus casei ( Lactobacillus casei ) CGMCC 1.574 production strain, and at the same time add 0.5% linoleic acid substrate, mix well and incubate at 37°C for 24h. After enrichment by this method, the resulting CLA isomers are c 9, t 11-CLA isomers ( figure 1 ), in the fermented product c 9, t The content of 11-CLA isomer is 0.46% by mass, and the conversion rate of linoleic acid is 92%. The concentration of the substrate linoleic acid has a significant impact on the synthesis of the product CLA. Under optimal condi...

Embodiment 2

[0022] After soaking 1 part of low-temperature defatted soybeans with 4 parts of water for 6 hours, coarsely grind and then finely grind once with a refiner, and then process twice with a colloid mill to obtain a mixed emulsion, after boiling, adjust the protein content in it to The mass percentage is 5%, and the skimmed milk powder with a mass percentage of 3% is added to obtain a basal medium. Add 1% fructo-oligosaccharides by mass to the basic medium, and pasteurize to obtain a bio-enriched medium. Insert 5% Lactobacillus casei ( Lactobacillus casei ) CGMCC 1.574 production strains, at the same time add 0.5% linoleic acid substrate, mix well and incubate at 37°C for 24h, the product c 9, t The content of 11-CLA isomer is 0.48% by mass. After the fermentation product is spray-dried or freeze-dried at low temperature, it is processed into tablets by pressing and coating, which can effectively prevent c 9, t The 11-CLA isomer undergoes an oxidation reaction during storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com