Universal method for controllably preparing nano particles on graphene sheet

A technology of nano-particles and graphene sheets, applied in the direction of nano-technology, heating inorganic powder coating, etc., can solve the problems of good conductivity, high preparation cost, and limitations, and achieve the effect of simple process and large synthesis amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

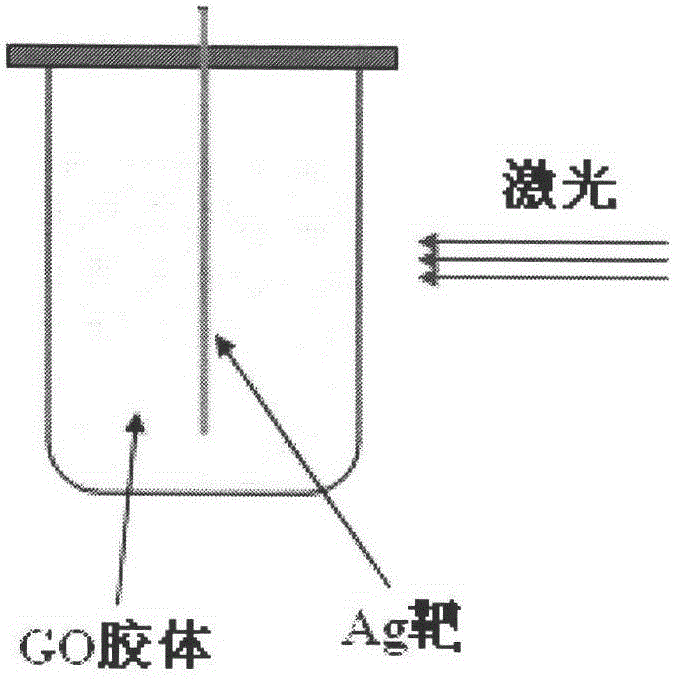

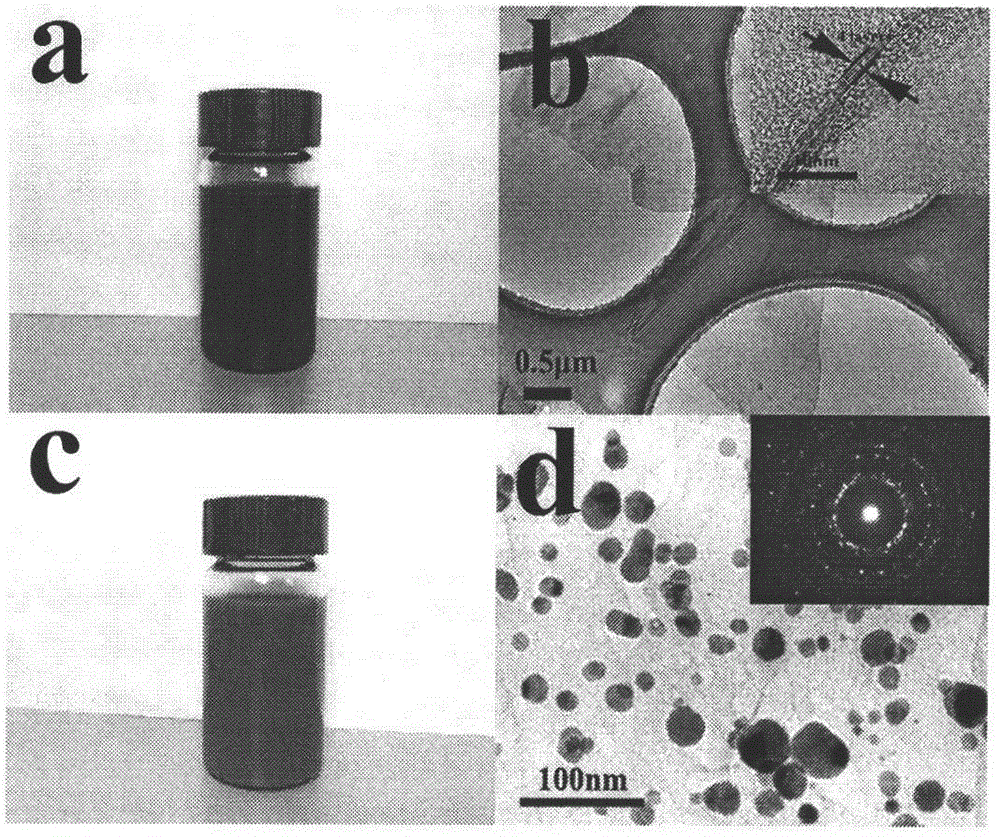

[0025] Select graphene oxide (GO) and H 2 The mass ratio of O is 0.2% colloidal aqueous solution and high-purity Ag target. Pour the GO colloidal aqueous solution into a beaker, then suspend the Ag target in the GO colloidal solution, and keep stirring the colloidal solution with a magnetic stirrer; finally select the wavelength The Nd:YAG laser with a frequency of 1064nm, a frequency of 10Hz, and a power greater than 40mJ / pulse irradiates the target, and Ag nanoparticles can be grown uniformly on the GO sheet. The density and size of the particles can be determined by the length of the irradiation time and the laser power. to control.

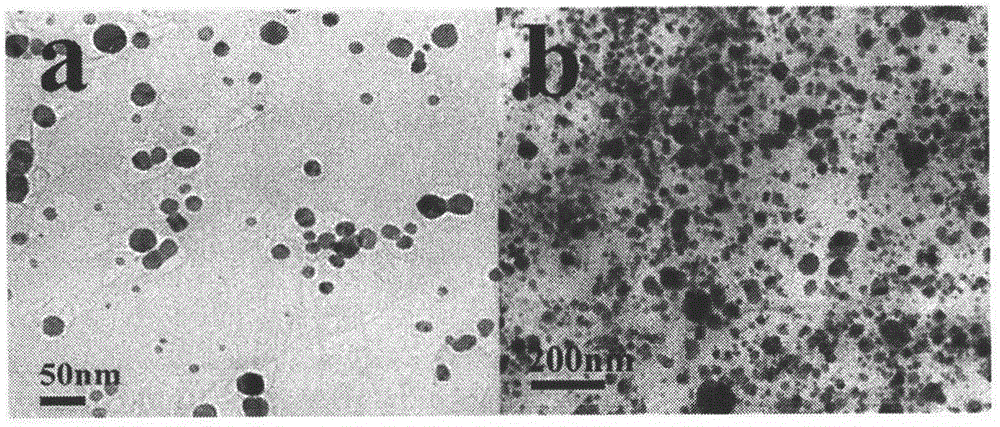

[0026] Tecnai F30 field emission transmission electron microscope (HRTEM, Tecnai F30, FEI) of Netherlands philips-FEI company was used to characterize the morphology and structure of the sample, as Figure 2-4 shown. The optical properties of the samples were analyzed by the In Via laser confocal Raman spectrometer from Renishwa, UK, such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com