A tail gas treatment device for a decompression diffusion system

An exhaust gas treatment and exhaust gas technology, which is applied in the directions of post-treatment, waste heat treatment, diffusion/doping, etc., can solve the problems affecting the service life of vacuum pumps, damage of vacuum pumps, air pollution, etc. Corrosion reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0032] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

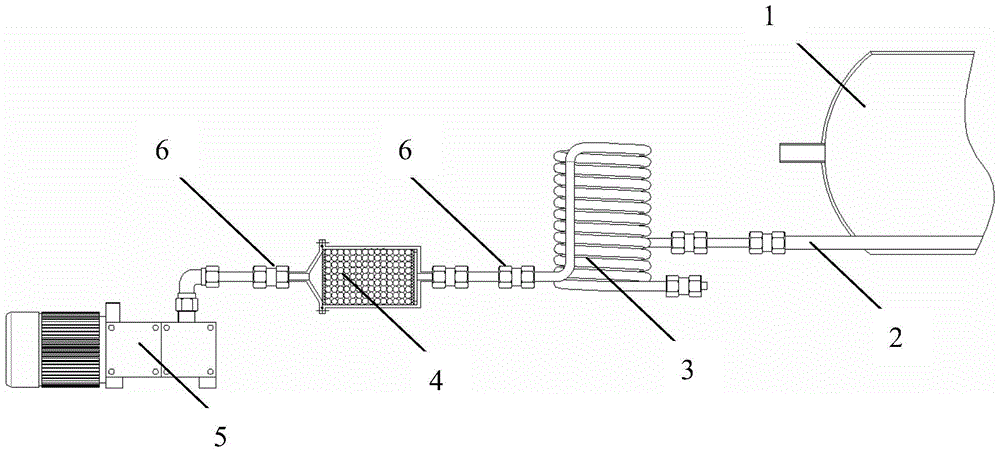

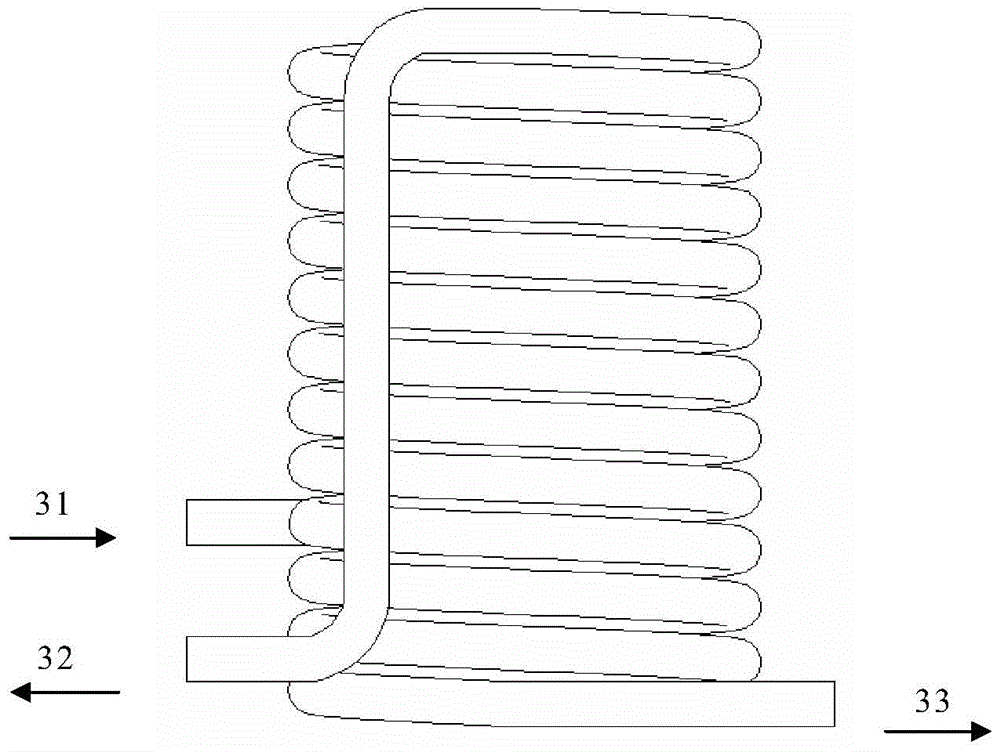

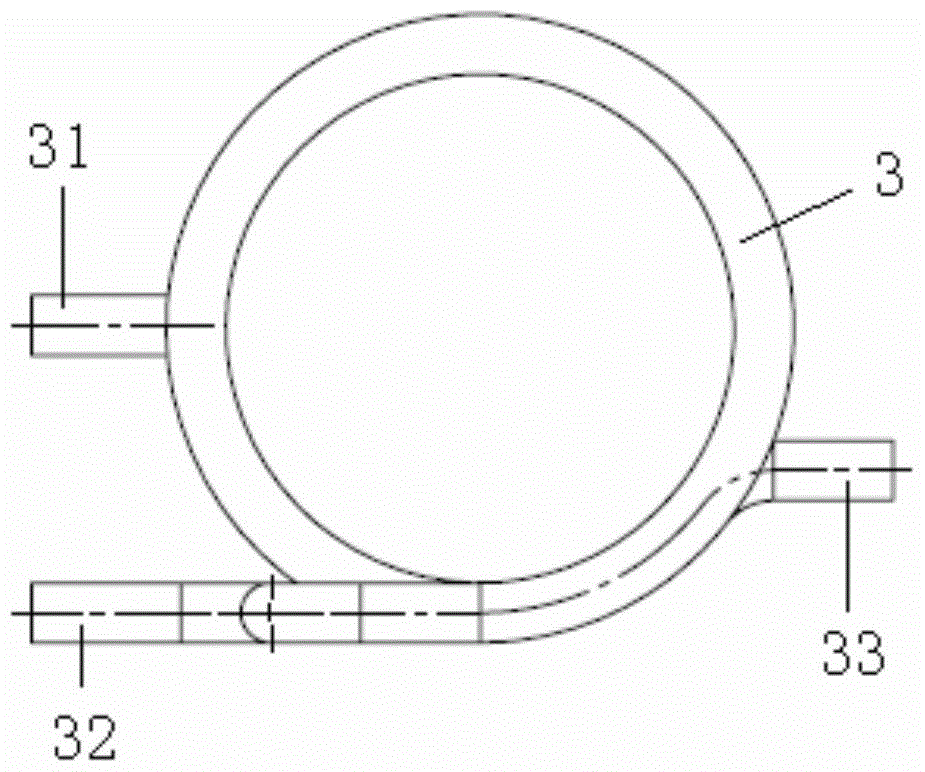

[0033] Such as Figure 1-Figure 6 As shown, a tail gas treatment device for a decompression diffusion system of the present invention consists of a quartz reaction tube 1, a tail gas outlet pipe 2 placed at the bottom of the quartz reaction tube, a tail gas condensation device 3, a tail gas neutralization bottle 4, and a vacuum pump 5 , connecting pipes and joints 6 and so on. The connection relationship of each component in the device is: the tail gas outlet pipe 2 of the quartz reaction tube 1 is connected with the inlet port 31 of the tail gas condensing device 3, the exhaust port 32 of the tail gas condensing device 3 is connected with the inlet port of the tail gas neutralization bottle 4 41 is connected, and the exhaust port 42 of the tail gas neutralization bottle 4 is connected with the vacuum pump 5, that is, the tail gas conden...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com