Flue gas purification and heat energy utilization system of AOD (Argon Oxygen Decarburization) refining furnace

A flue gas purification and refining furnace technology, which is applied in furnaces, waste heat treatment, furnace components, etc., can solve problems such as high system investment and operating costs, low economic value, and complicated design process, so as to improve efficiency and stabilize equipment operation performance, realize comprehensive utilization, and improve utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

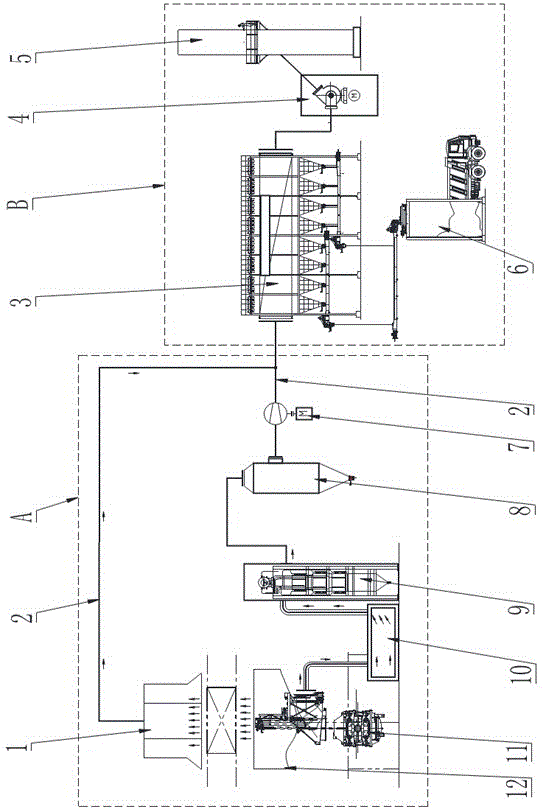

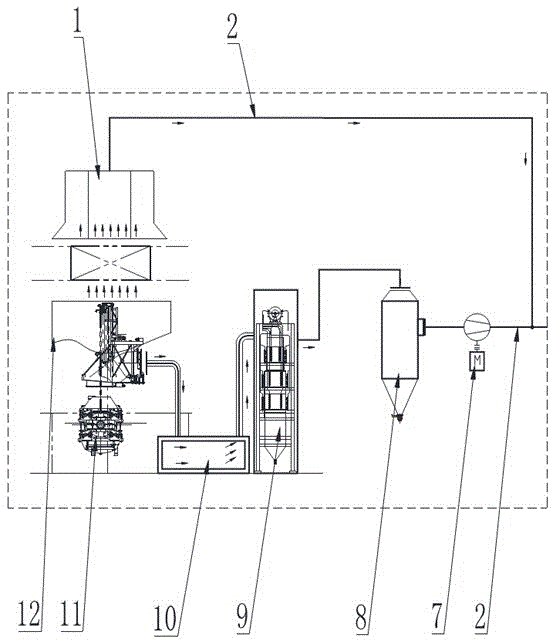

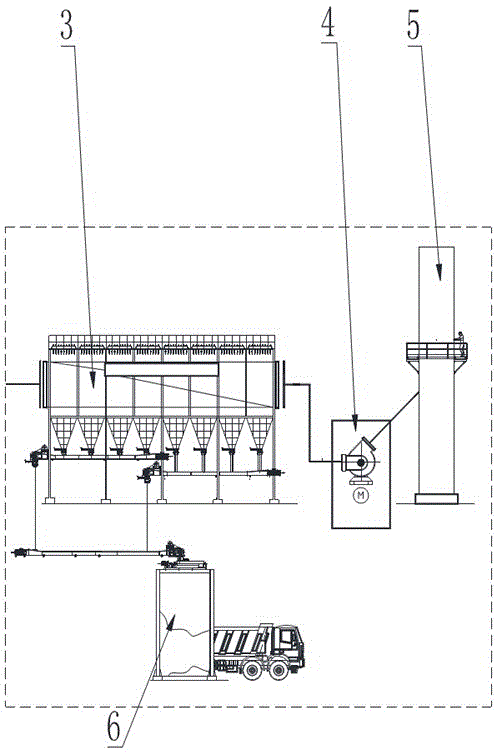

[0033] The technical solution adopted by the present invention is an AOD refining furnace flue gas purification and heat energy utilization system, which includes a refining furnace 11 and a furnace platform guide cover 12 covering the outside of the refining furnace 11. The upper end of the furnace platform guide cover 12 and the roof circulate The cover 1 is connected; the roof guide cover is connected with the pulse bag filter 3 through the flue gas pipeline; the furnace platform guide cover 12 collects the flue gas released from the refining furnace 11, and the refining furnace 11 overflows through the roof circulation cover 1 The flue gas is transported to the pulse bag filter 3 for processing;

[0034] The exhaust port on the refining furnace 11 passes the flue gas through the flue gas pipe 2 to the primary settling chamber 10, the preheating recovery device, the secondary settling chamber 8 and the pulse bag filter 3; the flue gas generated by the combustion of the refin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com