Method for reducing aluminum bar gap in thick aluminum evaporating coating process of integrated circuit

An evaporation coating and integrated circuit technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid devices, etc., can solve problems such as voids in the aluminum layer, achieve high mobility, facilitate popularization and application, and improve the effect of voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

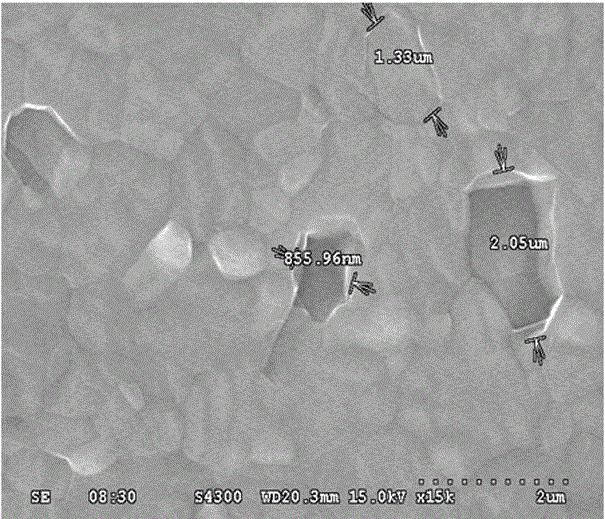

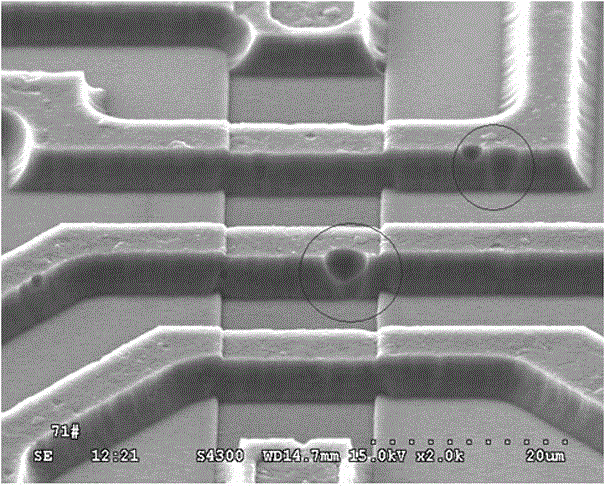

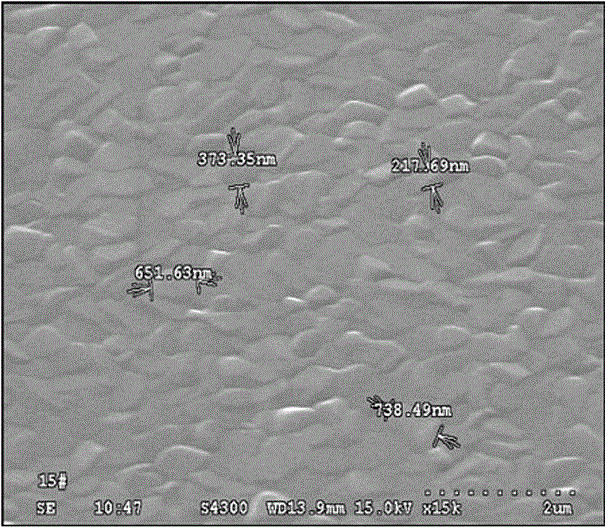

[0021] In order to further illustrate the present invention, through the comparison of the traditional pure aluminum process and the aluminum alloy process of the present invention, the improvement of the thick aluminum gap by the optimized aluminum alloy process is illustrated in conjunction with the accompanying drawings. Specific steps are as follows:

[0022] step one, Complete the front lead hole etching process.

[0023] Explanation: The dielectric under the metal layer is generally an oxide layer or silicon nitride, such as the dielectric layer I in the figure.

[0024] Step two, A 2.5um metal layer is deposited.

[0025] In order to describe the specific implementation mode and effect of the present invention more practically, the MARK 50 evaporation platform of CHA Industries Company was selected as the experimental machine. The machine adopts typical parameter settings, the cavity vacuum is 1.0E-6Torr, the substrate temperature is 130°C, and the evaporation rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com