Processed cheese and preparation method thereof

A technology for processed cheese and natural cheese, which is applied in cheese substitutes, dairy products, applications, etc. It can solve the problems of uneven distribution of fruit particles, insufficient delicate taste, and unclear chewing sensation, etc., and achieve rich variety, good texture, good smoothness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

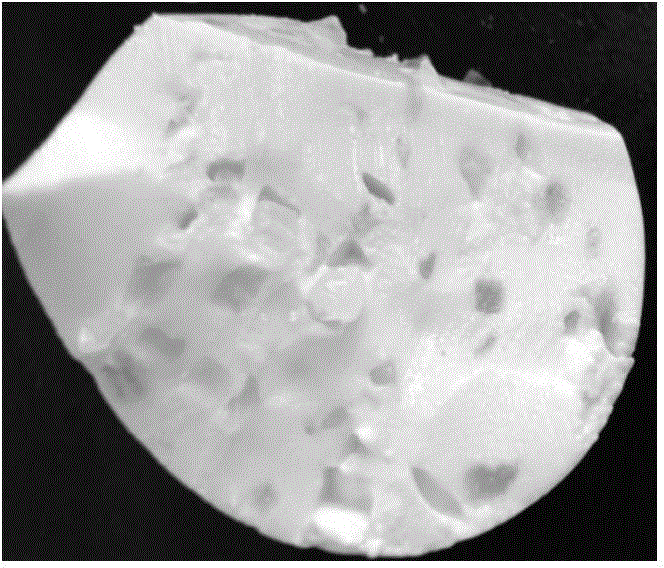

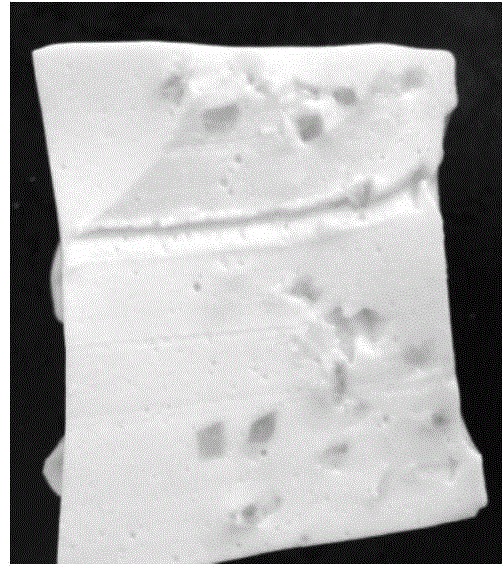

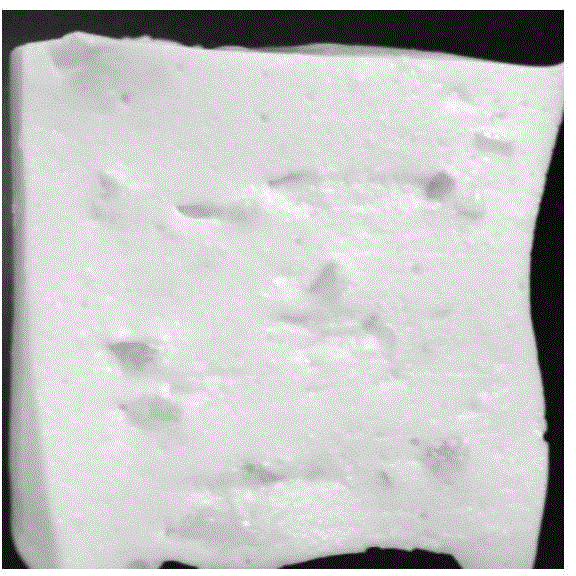

Image

Examples

Embodiment 1

[0056] Ingredients: Cheddar Salt 15%, Cream 30%, Sodium Hexametaphosphate 0.15%, Sodium Tripolyphosphate 0.05%, Whey Protein Concentrate 80 5%, White Sugar 15%, Sorbic Acid 0.10%, Lactic Acid 0.7%, carrageenan 0.7%, locust bean carob 0.1%, xanthan gum 0.3%, β-carotene 0.05%, fruit essence 0.04%, coconut fruit 3%, yellow peach 8%, purified Water is 21.81%.

[0057] Preparation:

[0058] ① According to the above raw material formula, cut the natural cheese in the raw material into pieces, then mix it evenly with emulsified salt, milk fat, sweetener, milk protein raw material, edible gum, essence and part of purified water, and pre-mix in the cheese melting pot for 30 seconds. Stir at a speed of 1000rpm, heat the steam directly to a temperature of 50°C, then keep warm for 3 minutes, and the steam pressure is 2.5bar;

[0059] ② Add the acidity regulator diluted with purified water until the concentration of the acidity regulator is 8%. After dilution, the acidity regulator is sl...

Embodiment 2

[0065] Ingredients: Salted Cheddar 5%, Unsalted Cheddar 10%, Unsalted Butter 15%, Sodium Hexametaphosphate 0.05%, Sodium Tripolyphosphate 0.15%, Whey Protein Concentrate 80 5%, White Sugar 20% %, 0.07% sorbic acid, 1.10% lactic acid, 0.70% carrageenan, 0.50% locust bean carob, 0.30% xanthan gum, 0.09% beta-carotene, 0.08% fruit flavor, 7% nata de coco , yellow peach fruit grains are 6%, and purified water is 28.96%.

[0066] Preparation:

[0067] ① According to the above raw material formula, cut the natural cheese in the raw material into pieces, then mix it evenly with emulsified salt, milk fat, sweetener, milk protein raw material, edible gum, essence and part of purified water, and pre-mix it in a cheese melting pot for 90 seconds. Stir at a speed of 2000rpm, steam is directly heated to a temperature of 60°C, and then kept for 7 minutes, and the steam pressure is 3.0bar;

[0068] ② Add the acidity regulator diluted with purified water until the concentration of the acidi...

Embodiment 3

[0074]Ingredients: Salted Cheddar 10%, Unsalted Cheddar 5.5%, Cream 28%, Unsalted Butter 2%, Sodium Hexametaphosphate 0.10%, Sodium Tripolyphosphate 0.10%, Whey Protein Concentrate 80 3.8 %, white sugar 18%, sorbic acid 0.09%, lactic acid 0.90%, carrageenan 0.50%, locust bean carob 0.33%, xanthan gum 0.26%, β-carotene 0.09%, fruit flavor 0.06%, 5% of coconut fruit, 8% of yellow peach, and 17.27% of purified water.

[0075] Preparation:

[0076] ① According to the above raw material formula, cut the natural cheese in the raw material into pieces, then mix it evenly with emulsified salt, milk fat, sweetener, milk protein raw material, edible gum, essence and part of purified water, and pre-mix it in a cheese melting pot for 60 seconds. Stir at a speed of 1500rpm, steam is directly heated to a temperature of 55°C, and then kept for 5 minutes, and the steam pressure is 2.7bar;

[0077] ② Add the acidity regulator diluted with purified water until the concentration of the acidity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com