Method of improving stability of finished enramycin premixing agent

A technology of enramycin and premix, which is applied in the directions of non-active ingredients medical preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc. Enramycin quality and other issues, to achieve the effect of stable quality, convenient transportation and application, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

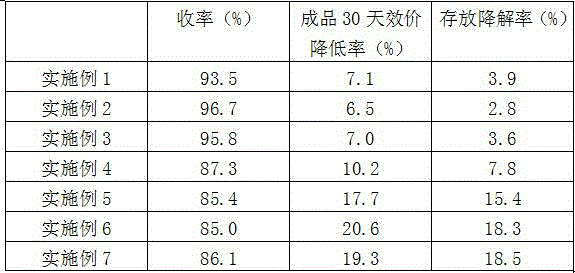

Examples

Embodiment 1

[0031] A method for improving the stability of the enramycin premix finished product is achieved through the following measures:

[0032] (1) Fermentation broth preparation: Put the enramycin-producing bacteria Streptomyces fungicidicus into the seed tank for seed culture, and connect the seed liquid to the fermenter at a 10% inoculation amount, and the seed culture condition is a temperature of 27 ℃, tank pressure 0.05MPa, aeration ratio v / v =1:1, cycle 29h, rotation speed 120rpm; fermentation conditions: temperature 27℃, tank pressure 0.03MPa, aeration ratio v / v =1:0.8, fermentation cycle 168h , speed 100rpm;

[0033] (2) Inactivation of fermentation broth: the fermentation broth is heated and inactivated for 30 minutes, and after inactivation, the temperature of the fermentation broth is lowered to 40-45 °C, and the temperature for heating and inactivation is 50 °C;

[0034] (3) Pretreatment method: first add chitosan solution with a mass concentration of 0.5% to the ferme...

Embodiment 2

[0039] A method for improving the stability of the enramycin premix finished product is achieved through the following measures:

[0040] (1) Fermentation broth preparation: Put the enramycin-producing bacteria Streptomyces fungicidicus into the seed tank for seed culture, and connect the seed liquid to the fermenter at a 10% inoculation amount, and the seed culture condition is a temperature of 28 ℃, tank pressure 0.05MPa, aeration ratio v / v =1:1, cycle 28h, rotation speed 120rpm; fermentation conditions: temperature 28°C, tank pressure 0.05MPa, aeration ratio v / v =1:0.90, fermentation cycle 192h , speed 120rpm;

[0041] (2) Fermentation broth inactivation: The fermentation broth is heated and inactivated for 30 minutes, and after inactivation, the temperature of the fermentation broth is lowered to 42°C, and the temperature for inactivation is 70°C;

[0042] (3) Pretreatment method: first add chitosan solution with a mass concentration of 0.5% to the fermented liquid after ...

Embodiment 3

[0046] A method for improving the stability of the enramycin premix finished product is achieved through the following measures:

[0047] (1) Fermentation broth preparation: Put the enramycin-producing bacteria Streptomyces fungicidicus into the seed tank for seed culture, and connect the seed liquid to the fermenter at a 10% inoculation amount, and the seed culture condition is a temperature of 28 ℃, tank pressure 0.05MPa, aeration ratio v / v =1:1, cycle 28h, rotation speed 120rpm; fermentation conditions: temperature 30°C, tank pressure 0.06MPa, aeration ratio v / v =1:1, fermentation cycle 216h , speed 140rpm;

[0048] (2) Fermentation broth inactivation: The fermentation broth is heated and inactivated for 30 minutes. After inactivation, the temperature of the fermentation broth is lowered to 40-45 ° C, and the temperature for heating and inactivation is 90 ° C;

[0049] (3) Pretreatment method: first add chitosan solution with a mass concentration of 0.5% to the fermented l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com