Negative-pressure ammonia distillation process and equipment for deaminizing ammonia before vacuum pump

A negative pressure ammonia distillation and vacuum pump technology, which is applied in ammonia preparation/separation, degassed water/sewage treatment, heating water/sewage treatment, etc., can solve the problem of shortening the maintenance and replacement cycle of vacuum pumps, uneven salt crystals, reducing Pump performance and other issues, to avoid adverse effects, reduce maintenance, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

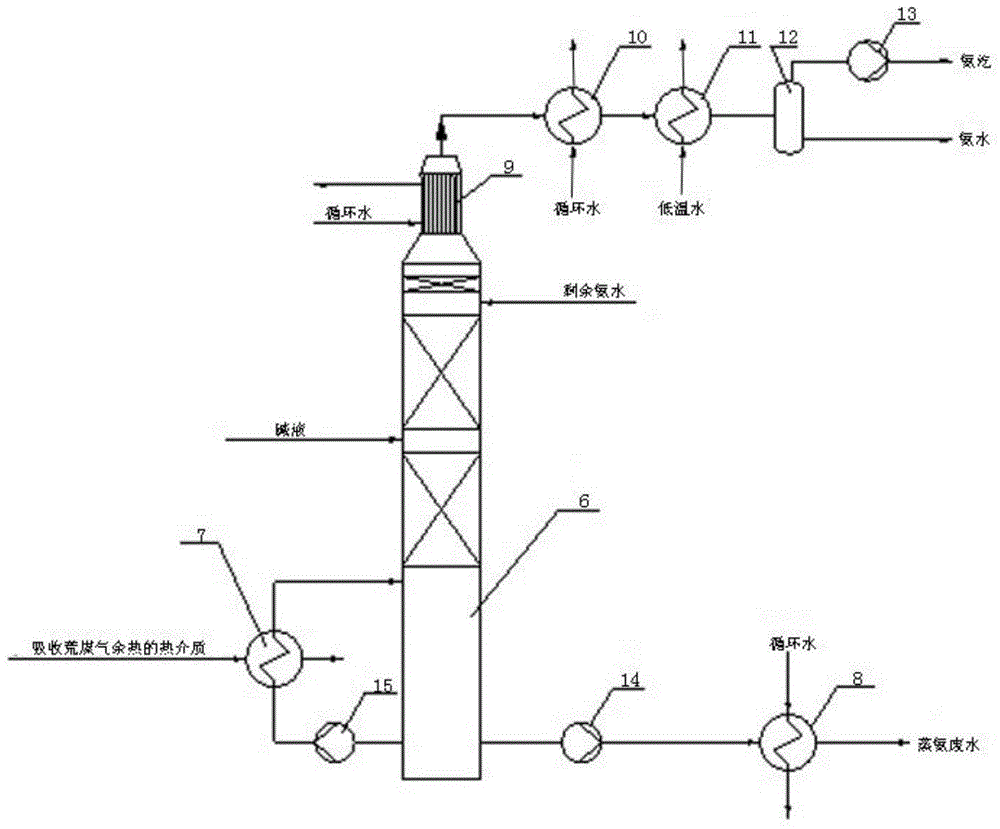

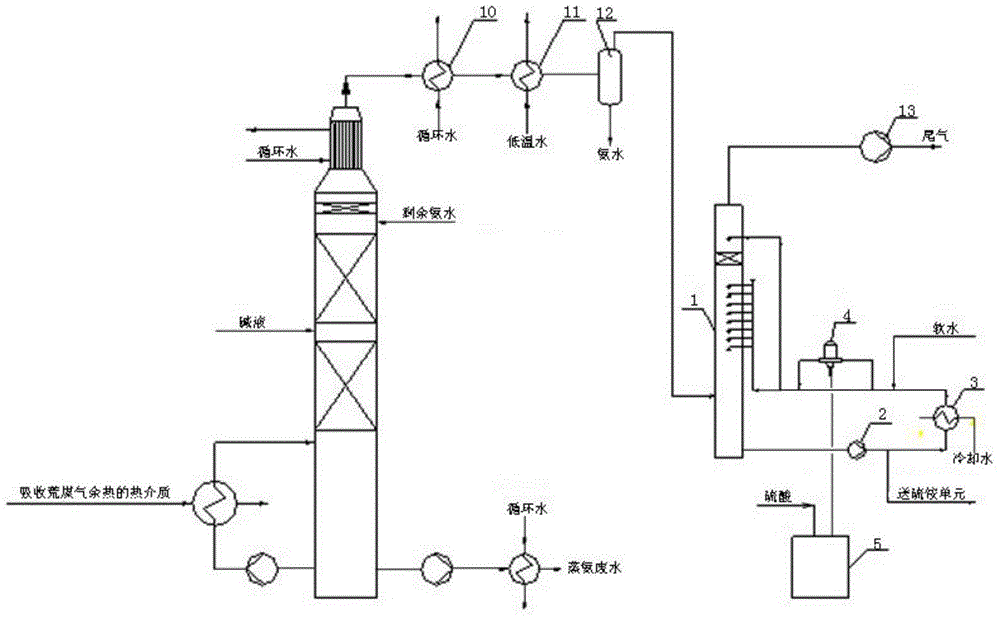

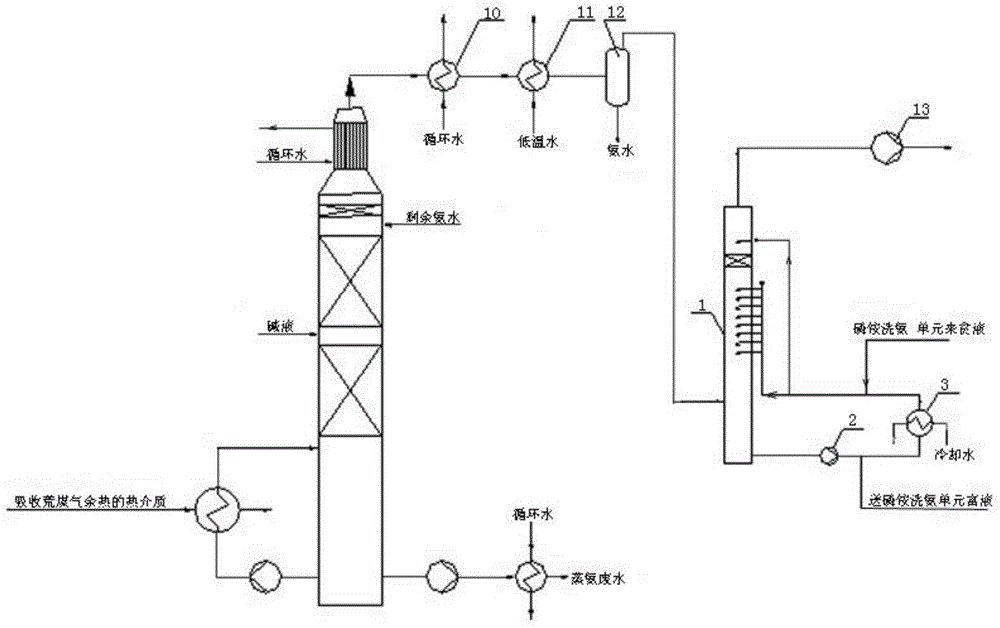

[0023] See figure 1 , is the negative pressure ammonia distillation process flow chart using the waste heat of raw gas as the heat source. Its working principle is to use the waste heat of raw gas as the heat source for ammonia distillation. The ammonia distillation waste water at the bottom of the ammonia distillation tower 6 and the circulating heat medium that has absorbed the waste heat of the raw gas are used as the heat source for ammonia distillation after heat exchange in the reboiler 7. The ammonia distillation tower 6 In a negative pressure state; the sodium hydroxide solution used to decompose the fixed ammonium salt in the remaining ammonia is directly added to the ammonia distillation tower 6, and the non-condensable gas condensed and cooled by the ammonia condenser 10 and the ammonia cooler 11 is pumped by a vacuum pump 13, Sent to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com