Amide-type bis-hydroxypropyl sulphobetaine surfactant as well as preparation method and application thereof

A technology of dihydroxypropyl sulfobeet and hydroxypropyl sulfobeet, which is applied in the direction of sulfonate preparation, chemical instruments and methods, transportation and packaging, etc. The preparation and application of betaine surfactants, etc., to achieve a good solubilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

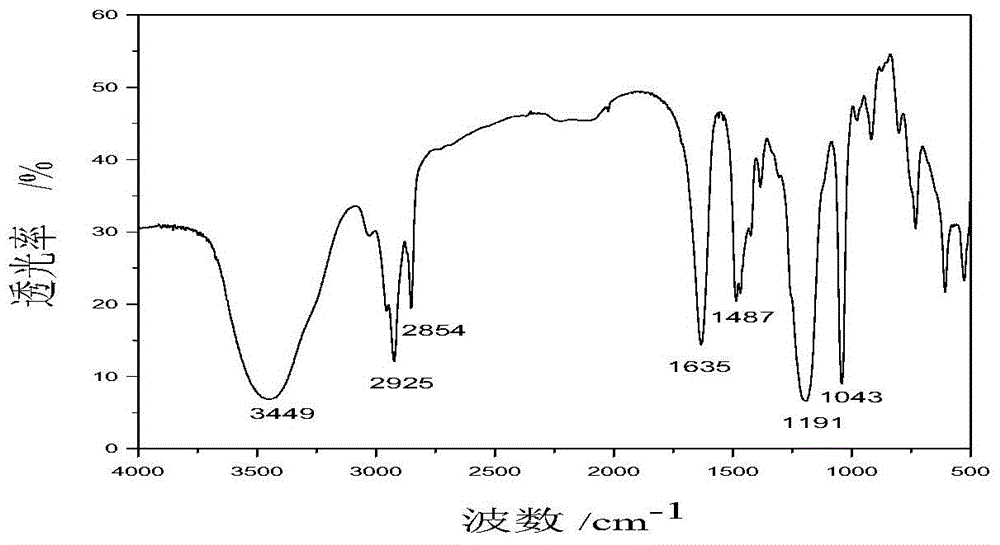

[0019] in N 2 Slowly add 0.2 mole of bis-N,N-(hydroxypropylsulfobetaine propyl) secondary amine in 100 mL of chloroform solution dropwise into a 500 mL three-neck flask containing stirred 0.19 mole of dodecanoyl chloride At the same time, hydrogen chloride is brought out by nitrogen gas, and the reaction is carried out at 5° C. for 8 hours, and the conversion rate of dodecanoic acid chloride is 99%. The obtained crude product was poured into 200mL of N,N-dimethylformamide, recrystallized 3 times, the solid was dried in vacuum for 48 hours, and the solvent was removed to obtain a light yellow solid of dodecylamide-type dihydroxypropyl sulfobetaine Surfactant, FT-IR diagram see figure 1 .

Embodiment 2

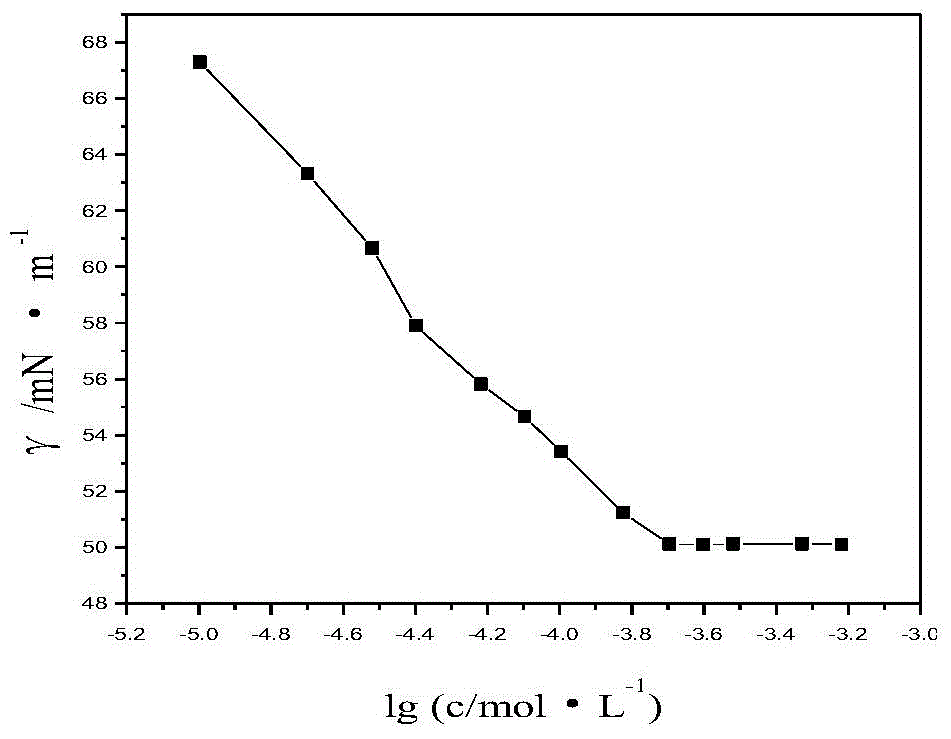

[0021] Referring to the preparation method and steps of Example 1, 0.2 moles of myristyl acid chloride was used instead of 0.19 moles of myristyl acid chloride, and the reaction was carried out at 10° C. for 6 hours, and the conversion rate of myristyl acid chloride was 98.3%. Dissolve the purified myristylamide type dihydroxypropyl sulfobetaine surfactant in ultrapure water, and measure surface tension and critical micelle concentration at 25°C. The results are as follows: figure 2 shown. Its critical micelle concentration is about 2.3×10 -4 mol / L, the lowest surface tension is 51.2mN / m.

Embodiment 3

[0023] Referring to the preparation method and steps of Example 1, 0.19 moles of lauric acid chloride was replaced by 0.2 moles of hexadecanoyl chloride, and the reaction was carried out at 10° C. for 8 hours, and the conversion rate of hexadecanoyl chloride was 98.0%. Dissolve the purified palmitoamide-type dihydroxypropyl sultaine surfactant in ultrapure water, and prepare the concentration to be 6.6×10 -4 mol / L, 2.2×10 -3 mol / L, 6.5×10 -3 mol / L, 2.3×10 -2 mol / L, 6.2×10 -2 mol / L solution, at 25°C, the molar solubilization ratio of polar organic substances such as nitrophenol (the molar solubilization ratio is the molar amount of organic substances solubilized by increasing the unit mole of surfactant micelles) is 1.036, logK =3.5, K is the partition coefficient of organic matter between the micelle phase / water phase, and the partition effect of nitrobenzene in the micelle phase is stronger, higher than its octanol-water partition coefficient (lgK ow =1.85), it can be see...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com