Modified-chitosan and graphite oxide magnetic nano absorbent and preparation and application thereof

A magnetic nanometer and magnetic nanoparticle technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., to achieve simple methods, improved adsorption capacity and selectivity, and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

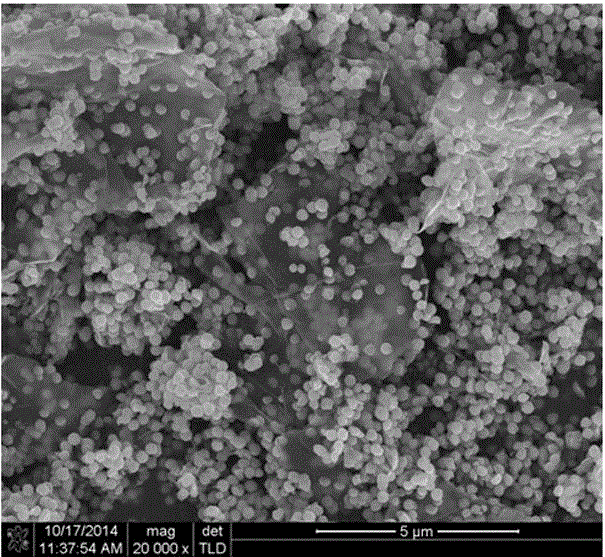

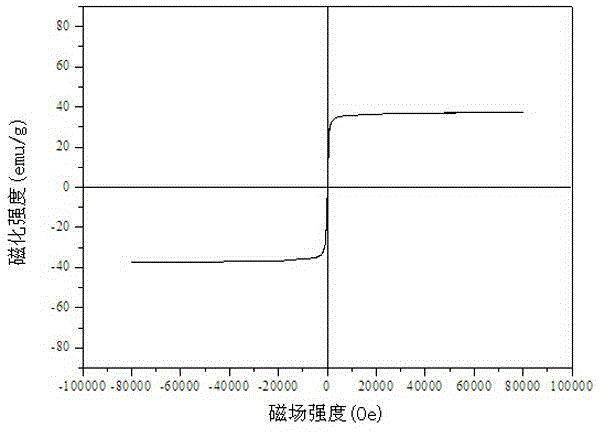

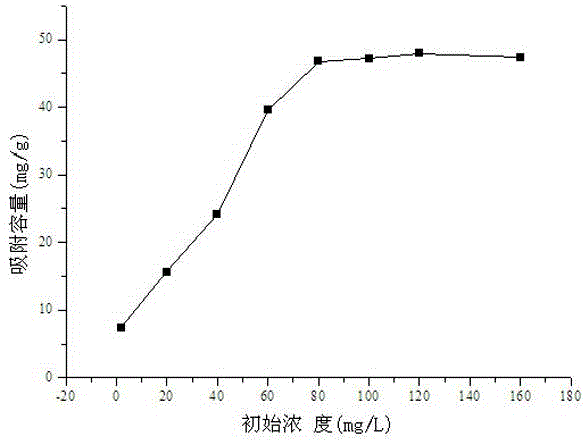

[0022] Preparation of Chitosan Modified Graphite Oxide Magnetic Nanosorbent

[0023] (1) Preparation of graphite oxide: put a 1000 mL beaker into a low-temperature reaction bath, cool to 0°C, add 300 mL of 98% concentrated sulfuric acid and 20 mL of concentrated phosphoric acid, and stir well. Add 2 g of natural flake graphite and 15 g of potassium permanganate while stirring, and then continue to stir for 20 minutes to ensure thorough mixing. Slowly warm up to 50°C and stir for 10h. After the reaction, transfer the reaction system into a 2000 mL beaker, add deionized water to dilute the reaction solution to 1000 mL, and add a certain amount of H 2 o 2 (3%), the reaction solution will turn golden yellow at this moment. Filter while hot, then wash the filter cake with 5% HCl solution and deionized water until there is no sulfate ion in the filtrate (use BaCl 2 solution detection). The filter cake was dried in a vacuum oven at 60 °C for 48 h. Grind through a 200-mesh siev...

Embodiment 2

[0026] Preparation of Chitosan Modified Graphite Oxide Magnetic Nanosorbent

[0027] (1) Preparation of graphite oxide: put a 1000 mL beaker into a low-temperature reaction bath, cool to 0 °C, add 360 mL of 98% concentrated sulfuric acid and 40 mL of concentrated phosphoric acid, and stir well. Add 3 g of natural flake graphite and 18 g of potassium permanganate while stirring, and then continue stirring for 30 min to ensure thorough mixing. Slowly raise the temperature to 50°C and stir for 12 h. After the reaction, the reaction system was transferred to a 2000 mL beaker, and deionized water was added to dilute the reaction solution to 1400 mL, and a certain amount of H 2 o 2 (3%), the reaction solution will turn golden yellow at this moment. Filter while hot, then wash the filter cake with 5% HCl solution and deionized water until there is no sulfate ion in the filtrate (use BaCl 2 solution detection). The filter cake was dried in a vacuum oven at 60 °C for 48 h. Grind...

Embodiment 3

[0030] Preparation of Chitosan Modified Graphite Oxide Magnetic Nanosorbent

[0031] (1) Preparation of graphite oxide: put a 1000 mL beaker into a low-temperature reaction bath, cool to 0 °C, add 330 mL 98% concentrated sulfuric acid and 30 mL concentrated phosphoric acid, and stir well. Add 2.5 g of natural flake graphite and 16.5 g of potassium permanganate during stirring, and then continue stirring for 25 minutes to ensure thorough mixing. Slowly warm up to 50°C and stir for 11h. After the reaction, transfer the reaction system into a 2000 mL beaker, add deionized water to dilute the reaction solution to 1200 mL, and add a certain amount of H 2 o 2 (3%), the reaction solution will turn golden yellow at this moment. Filter while hot, then wash the filter cake with 5% HCl solution and deionized water until there is no sulfate ion in the filtrate (use BaCl2 solution detection). The filter cake was dried in a vacuum oven at 60 °C for 48 h. Grind through a 200-mesh sieve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com