Preparation method of nano-FePd catalyst, products by preparation method and application of preparation method

A catalyst and nanotechnology, applied in the field of catalyst material research, to achieve the effects of improving activity, facilitating precipitation and separation, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

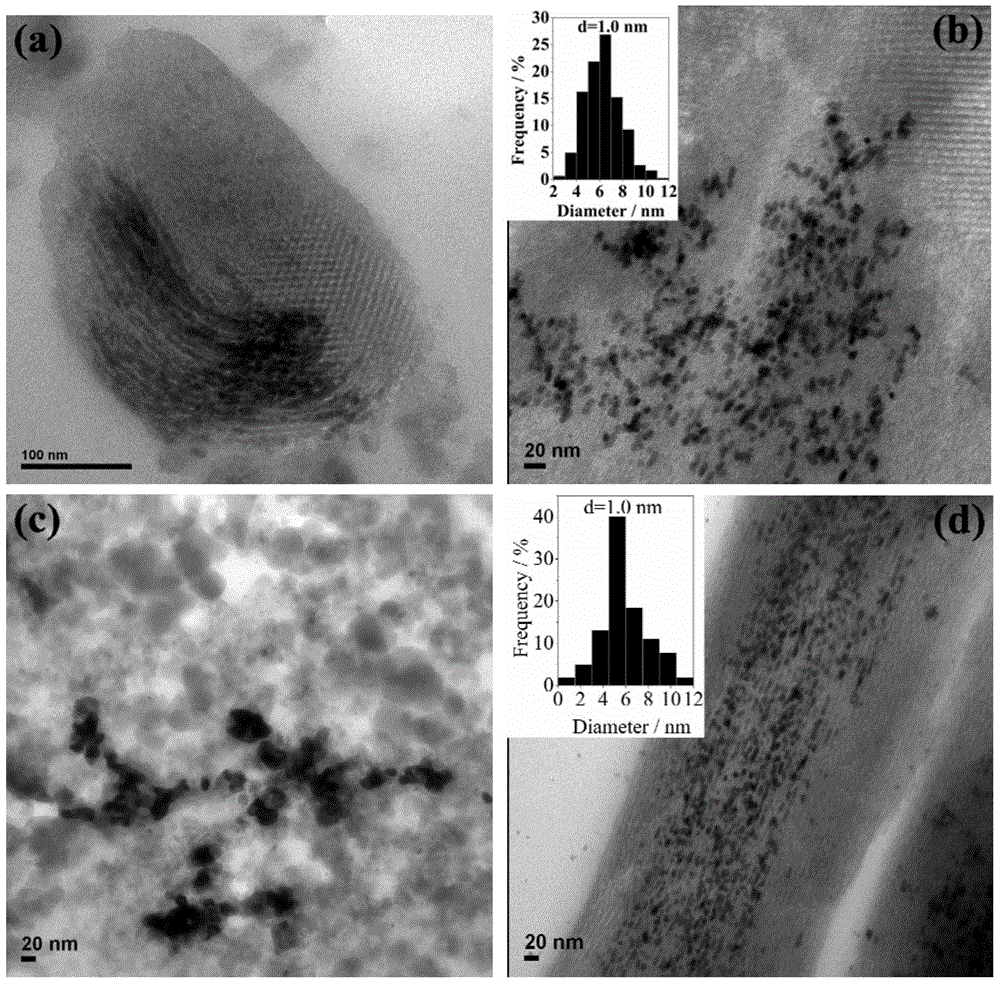

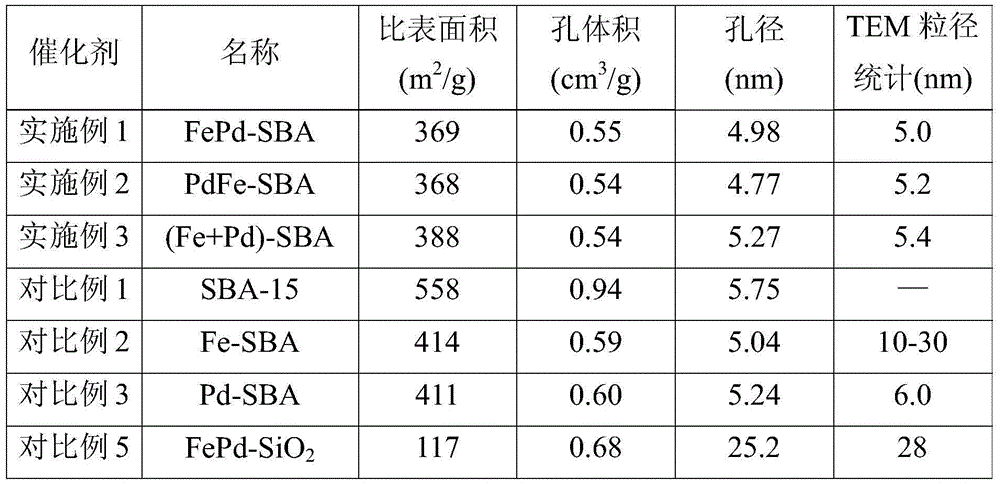

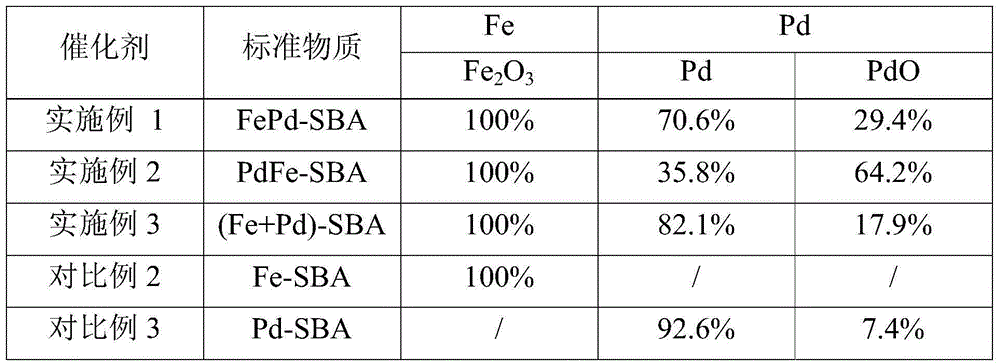

Embodiment 1

[0040] Take 1g of mesoporous SBA-15 (SiO 2 / Al 2 o 3 ≥500, BET:400-600m 2 / g, pore size 6-8nm) sample, equal volume impregnated in the concentration of 0.1885mol / L Fe(NO 3 ) 3 In the aqueous solution, dry it at room temperature, dry it in an oven at 105°C to remove residual moisture, and place it in a tube furnace for roasting at 400°C for 4 hours. The calcined sample was immersed in 0.0100mol / L PdCl 2 In the aqueous solution, dry at 105°C and bake at 400°C for 4 hours. The obtained sample was placed in a tube furnace, H 2 The FePd-SBA catalyst with loading of 5% Fe and 5% Pd was prepared by reduction at 200°C for 2 hours under atmospheric conditions.

Embodiment 2

[0042] Take 1g of mesoporous SBA-15 (SiO 2 / Al 2 o 3 ≥500, BET:400-600m 2 / g, pore size 6-8nm) sample, equal volume impregnated in PdCl concentration of 0.0100mol / L 2 In the aqueous solution, dry it at room temperature, dry it in an oven at 105°C to remove residual moisture, and place it in a tube furnace for roasting at 400°C for 4 hours. The calcined samples were impregnated in 0.1885mol / L Fe(NO 3 ) 3 In the aqueous solution, dry at 105°C and bake at 400°C for 4 hours. The obtained sample was placed in a tube furnace, H 2 The PdFe-SBA catalyst with loading capacity of 5% Pd and 5% Fe was prepared by reduction at 200°C for 2 hours under atmospheric conditions.

Embodiment 3

[0044] Take 1g of mesoporous SBA-15 (SiO 2 / Al 2 o 3 ≥500, BET:400-600m 2 / g, pore size 6-8nm) sample, equal volume impregnated in the concentration of 0.1885mol / L Fe(NO 3 ) 3 and 0.0100mol / L PdCl 2 In the mixed aqueous solution, dry it at room temperature, dry it in an oven at 105°C to remove residual moisture, and place it in a tube furnace for roasting at 400°C for 4 hours. The obtained sample was placed in a tube furnace, H 2 Reduction at 200° C. for 2 hours under atmospheric conditions prepared a (Fe+Pd)-SBA catalyst with loadings of 5% Fe and 5% Pd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com