Multistage meso-porous ZSM-5 catalyst as well as preparation method and application method thereof

A ZSM-5 and catalyst technology, which is applied in the field of multi-level mesoporous ZSM-5 catalysts, can solve the problems of pore structure distortion, damage, collapse and the like, and achieve the effect of a simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

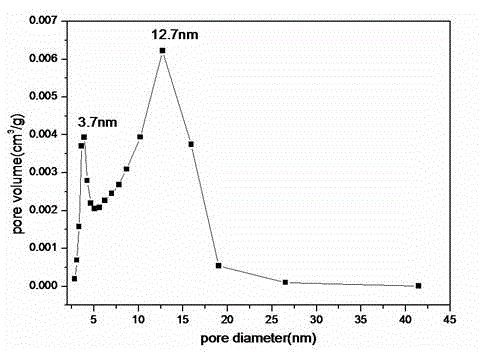

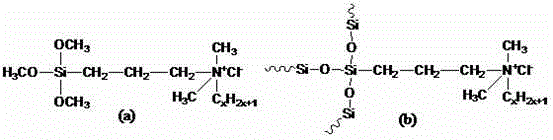

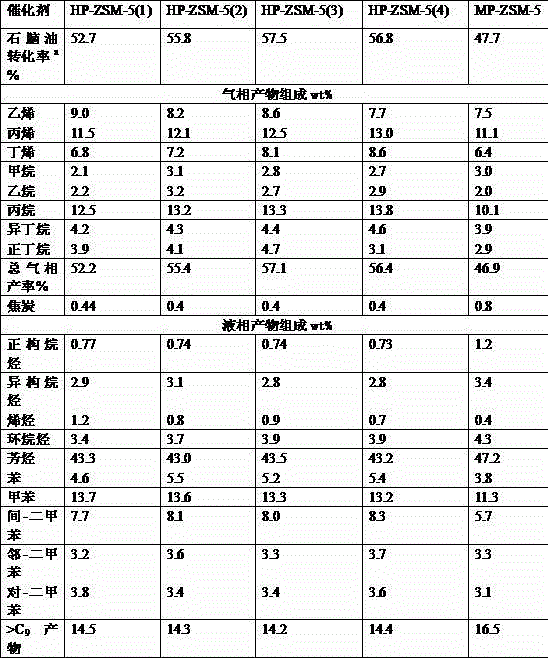

[0019] Preparation of Hierarchical Mesoporous ZSM-5 Zeolite Catalyst ((MeO) 3 SiC 3 h 6 (Me 2 )C 12 N + Cl - as template), marked as HP-ZSM-5(1).

[0020] (1) Na 2 SiO 3 , NaAlO 2 , NaOH, TPAOH, (MeO) 3 SiC 3 h 6 (Me 2 )C 12 N + Cl - , mixed with water, the molar ratio is 1SiO 2 / 0.05Al 2 o 3 / 0.15Na 2 O / 0.17TPAOH / 0.035(MeO) 3 SiC 3 h 6 (Me 2 )C x N + Cl - / 25H 2 O. After stirring evenly, aging at 100°C for 2h. Then transfer to a polytetrafluoroethylene-lined stainless steel kettle, and crystallize at 100° C. for 5 days at a stirring speed of 22 rpm.

[0021] (2) The product obtained in step (1) was washed with water, and the solid obtained after centrifugation was dried at 50°C for 12 hours.

[0022](3) The product after drying in step (2) was heated in a muffle furnace at a rate of 1°C / min to 550°C for 5 hours and calcined to remove the organic template to obtain the catalyst.

Embodiment 2

[0024] Preparation of Hierarchical Mesoporous ZSM-5 Zeolite Catalyst ((MeO) 3 SiC 3 h 6 (Me 2 )C 14 N + Cl - as template), marked as HP-ZSM-5(2).

[0025] (1) Ethyl silicate, pseudoboehmite (70%Al 2 o 3 ), NaOH, TPAOH, (MeO) 3 SiC 3 h 6 (Me 2 )C 14 N + Cl - Mix with water, the molar ratio is 1SiO 2 / 0.07Al 2 o 3 / 0.15Na 2 O / 0.24TPAOH / 0.045(MeO) 3 SiC 3 h 6 (Me 2 )C x N + Cl - / 28H 2 O. After stirring evenly, aging at 100°C for 2.5h. Then transfer to a polytetrafluoroethylene-lined stainless steel kettle, and crystallize at 120° C. for 7 days at a stirring speed of 25 rpm.

[0026] (2) The product obtained in step (1) was washed with water, and the solid obtained after centrifugation was dried at 60°C for 12 hours.

[0027] (3) The product after drying in the step (2) was heated in a muffle furnace at a rate of 1°C / min to 570°C for 8 hours and calcined to remove the organic template to obtain the catalyst.

Embodiment 3

[0029] Preparation of Hierarchical Mesoporous ZSM-5 Zeolite Catalyst ((MeO) 3 SiC 3 h 6 (Me 2 )C 16 N + Cl - as template), labeled as HP-ZSM-5(3).

[0030] (1) Ethyl silicate, aluminum isopropoxide, NaOH, TPAOH, (MeO) 3 SiC 3 h 6 (Me 2 )C 16 N + Cl - Mix with water, the molar ratio is 1SiO 2 / 0.08Al 2 o 3 / 0.15Na 2 O / 0.36TPAOH / 0.055(MeO) 3 SiC 3 h 6 (Me 2 )C 16 N + Cl - / 30H 2 O. After stirring evenly, aging at 100°C for 3h. Then transfer to a polytetrafluoroethylene-lined stainless steel kettle, and crystallize at 140° C. for 6 days at a stirring speed of 40 rpm.

[0031] (2) The product obtained in step (1) was washed with water, and the solid obtained after centrifugation was dried at 65°C for 12 hours.

[0032] (3) The product dried in step (2) was heated in a muffle furnace at a rate of 1°C / min to 620°C and calcined for 8 hours to remove the organic template to obtain the catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com