Roller repair layer and roller repair method

A technology for repairing layers and rolls, which is applied in the direction of keeping roll equipment in an effective state, coating, metal rolling, etc., can solve the problems that are not widely used, and the coating is easy to detach, and achieve excellent matrix bonding strength, equipment and The process is simple and the effect of preventing thermal stress mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

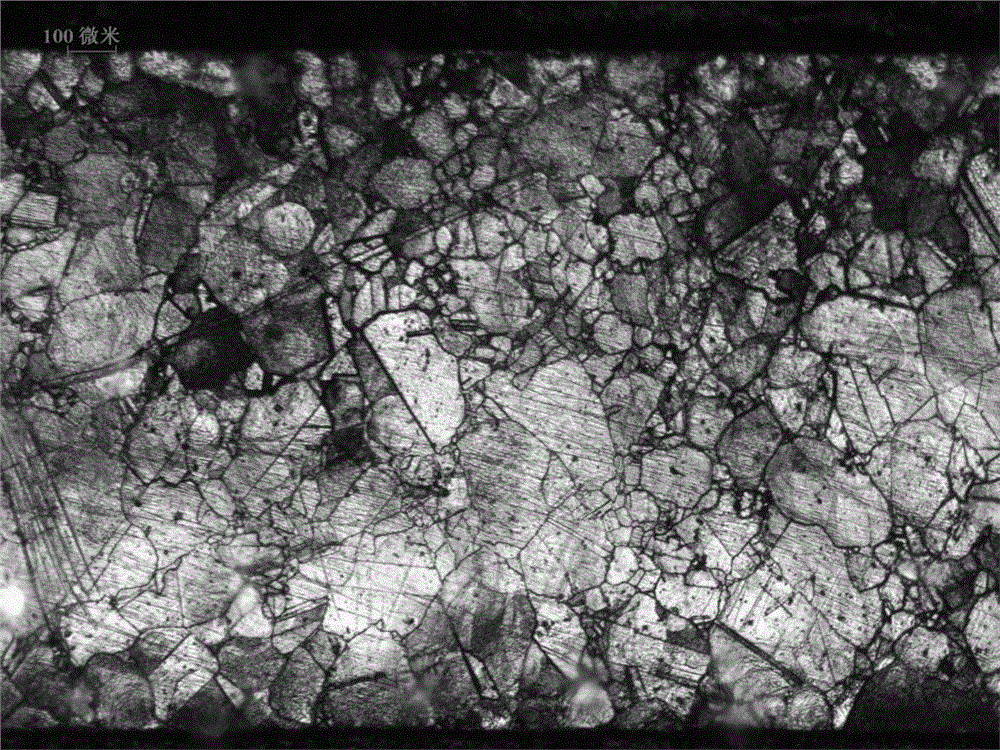

Image

Examples

Embodiment 1

[0047] In this embodiment, a repair layer is prepared on the surface of the substrate with the scrapped roll as the substrate. The repair layer is composed of NiAl coating, NiAl-Cr 2 o 3 Composite coating and Cr 2 o 3 Coating composition. In this example, the NiAl coating thickness is 100 μm, NiAl-Cr 2 o 3 Composite coating thickness is 800μm, Cr 2 o 3 The coating thickness is 200 μm.

[0048] The NiAl coating is prepared by thermal spraying of commercially available 15-45μm NiAl powder, Cr 2 o 3 The coating is made of commercially available 20~60μm Cr 2 o 3 Powder prepared by thermal spraying method, NiAl-Cr 2 o 3 Composite coating is the above NiAl and Cr 2 o 3 The powder is mixed according to the mass ratio of 15:85 and prepared by thermal spraying method.

[0049] The specific preparation method of the repair layer is as follows:

[0050] Before spraying, clean the substrate, remove oil and rust, and use 20-mesh alloy sand for surface blasting pretreatment ...

Embodiment 2

[0060] In this embodiment, a repair layer is prepared on the surface of the substrate with the scrapped roll as the substrate. The repair layer is composed of NiCrBSiFe coating, NiCrBSiFe-Cr coating from the substrate surface to the outside. 2 o 3 Composite coating and Cr 2 o 3 Coating composition. In this embodiment, the thickness of the NiCrBSiFe coating is 90 μm, and the NiCrBSiFe-Cr 2 o 3 Composite coating thickness is 850μm, Cr 2 o 3 The coating thickness is 200 μm.

[0061] The NiCrBSiFe coating is prepared by thermal spraying method of commercially available NiCrBSiFe powder of 15~45μm, Cr 2 o 3 The coating is made of commercially available 20~60μm Cr 2 o 3 Powder prepared by thermal spraying method, NiCrBSiFe-Cr 2 o 3 Composite coating is the above NiCrBSiFe and Cr 2 o 3 The powder is mixed according to the mass ratio of 20:80 and prepared by thermal spraying method.

[0062] The specific preparation method of the above repair layer is the same as the pr...

Embodiment 3

[0068] In this embodiment, a repair layer is prepared on the surface of the substrate with the scrapped roll as the substrate. The repair layer is composed of NiAl coating, NiAl-Cr 3 C 2 Composite coating and Cr 3 C 2 Coating composition. NiAl coating thickness is 110μm, NiAl-Cr 3 C 2 Composite coating thickness is 850μm, Cr 3 C 2 The coating thickness is 250 μm.

[0069] The NiAl coating is prepared by thermal spraying of commercially available 15-45μm NiAl powder, Cr 3 C 2 The coating is made of commercially available 15~45μm Cr 3 C 2 Powder prepared by thermal spraying method, NiAl-Cr 3 C 2 Composite coating is the above NiAl and Cr 3 C 2 The powder is mixed according to the mass ratio of 20:80 and prepared by thermal spraying method.

[0070] The specific preparation method of the above-mentioned repair layer is the same as the preparation method in Example 1, the difference is that the powders are respectively NiAl and Cr 3 C 2 powder to obtain a repair l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com