A method for regulating the diameter of silver nanowires by using the amount of sodium chloride

A technology of silver nanowires and sodium chloride, applied in the direction of nanotechnology, can solve the problems of changing the length of silver nanowires, and achieve the effects of low cost, mild reaction conditions, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

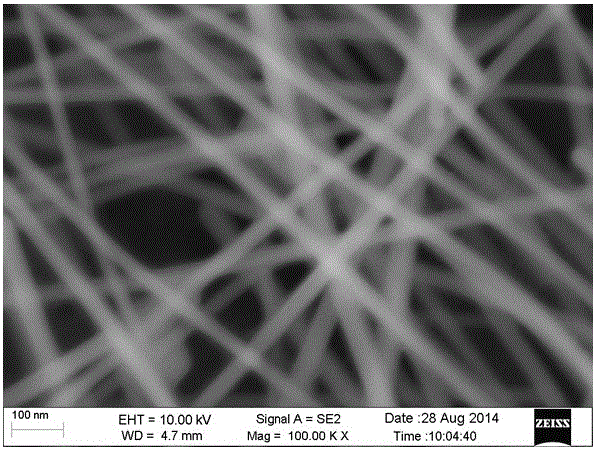

[0028] Preparation of silver nanowires with a diameter of 30 nm

[0029] (1) Mix and dissolve 0.47g silver nitrate, 0.2mL water and 1mL glycerol at room temperature to make solution A;

[0030] (2) Add 4.4mg of sodium chloride, 2.1g of polyvinylpyrrolidone and 59mL of glycerol to a 250mL three-neck round-bottom flask in sequence, cover the three-neck round-bottom flask with a stopper, and suspend in an oil bath at 180 degrees Celsius Solution B was prepared by heating for 1 hour.

[0031] (3) Add solution A to solution B and keep it warm at 180 degrees Celsius for 15 minutes to obtain silver nanowires.

[0032] (4) After the reaction, the reaction solution was centrifuged, and the lower precipitate was washed to obtain silver nanowires. The prepared silver nanowires have an average diameter of 30 nanometers and a length of 2-20 micrometers.

Embodiment 2

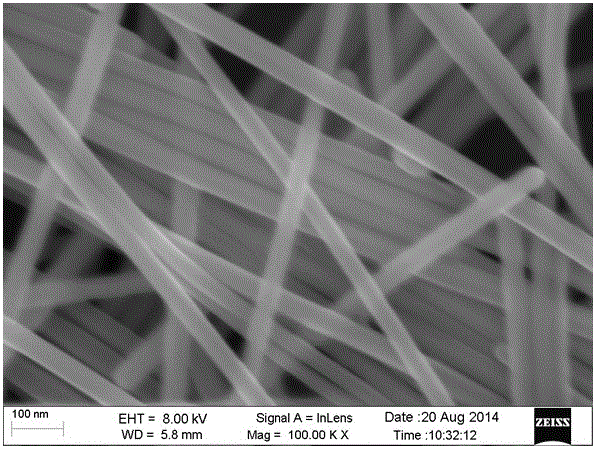

[0034] Preparation of silver nanowires with a diameter of 40 nm

[0035] (1) Mix and dissolve 0.47g silver nitrate, 0.2mL water and 1mL glycerol at room temperature to make solution A;

[0036] (2) Add 17.7mg of sodium chloride, 2.1g of polyvinylpyrrolidone and 59mL of glycerol in sequence to a 250mL three-neck round-bottom flask, cover the three-neck round-bottom flask with a stopper, and suspend in an oil bath at 180 degrees Celsius Solution B was prepared by heating for 1 hour.

[0037] (3) Add solution A to solution B and keep it warm at 180 degrees Celsius for 15 minutes to obtain silver nanowires.

[0038] (4) After the reaction, the reaction solution was centrifuged, and the lower precipitate was washed to obtain silver nanowires. The prepared silver nanowires have an average diameter of 40 nanometers and a length of 2-20 micrometers.

Embodiment 3

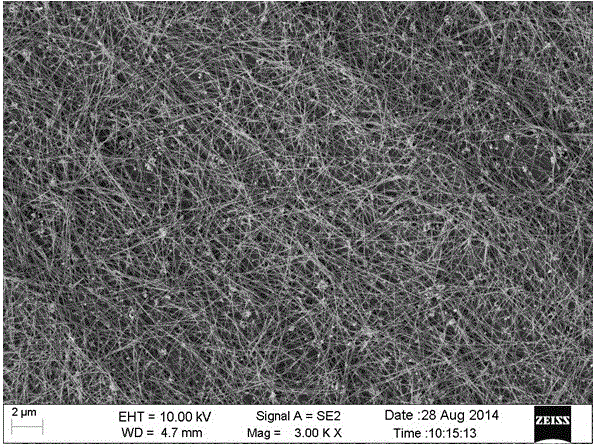

[0040] Preparation of silver nanowires with a diameter of 60 nm

[0041] (1) Mix and dissolve 0.47g silver nitrate, 0.2mL water and 1mL glycerol at room temperature to make solution A;

[0042] (2) Add 35.4mg of sodium chloride, 2.1g of polyvinylpyrrolidone and 59mL of glycerol to a 250mL three-neck round-bottom flask in sequence, cover the three-neck round-bottom flask with a stopper, and suspend in an oil bath at 180 degrees Celsius Solution B was prepared by heating for 1 hour.

[0043] (3) Add solution A to solution B and keep it warm at 180 degrees Celsius for 15 minutes to obtain silver nanowires.

[0044] (4) After the reaction, the reaction solution was centrifuged, and the lower precipitate was washed to obtain silver nanowires. The prepared silver nanowires have an average diameter of 60 nanometers and a length of 2-20 micrometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com