High-molecular heavy metal flocculant and preparation method thereof

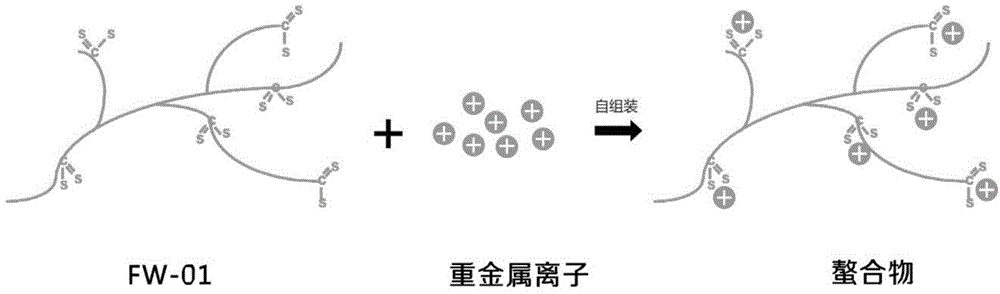

A heavy metal and flocculant technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, special compound water treatment, etc., can solve the problems of unstable residue, difficult recovery of precious metals, slow reaction, etc., and achieve molecular structure design Novel, strong heavy metal chelating ability, improved flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

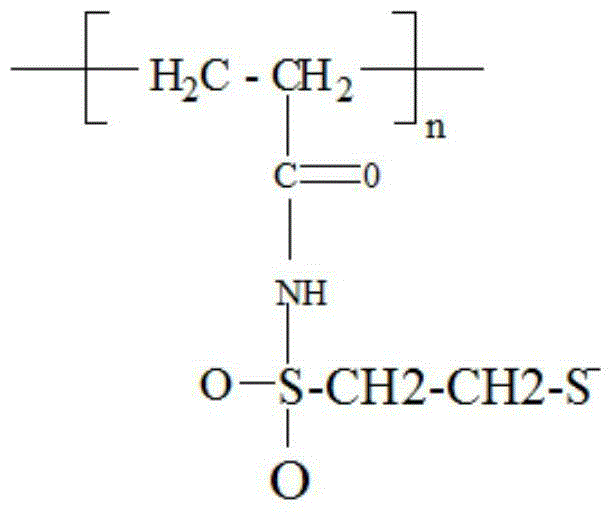

[0043] A polymer heavy metal flocculant, the structural formula of its main component is as follows:

[0044]

[0045] Wherein n is an integer of 20-3000.

[0046] Preferably in the present invention, the appearance of the polymer heavy metal flocculant is white powder, and its solution is a colorless transparent liquid.

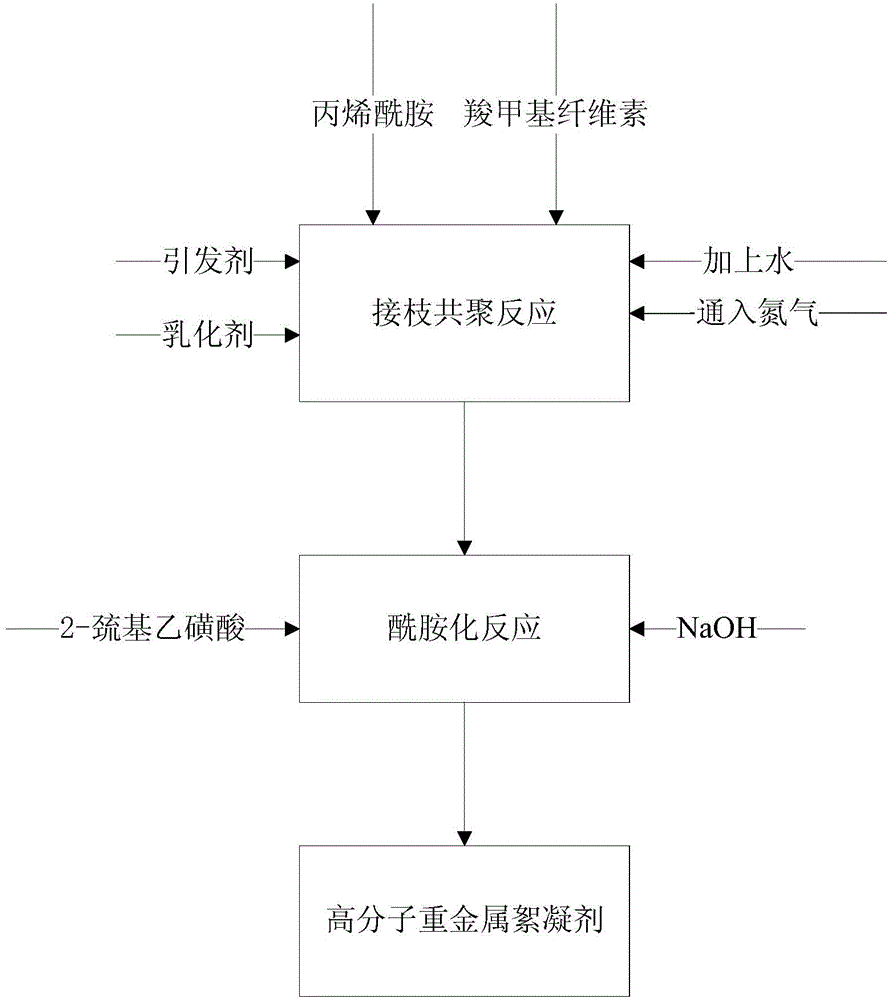

[0047] A preparation method of polymer heavy metal flocculant, comprising the following steps:

[0048] Step 1, put a part of carboxymethyl cellulose and acrylamide into the reactor at a mass ratio of 1:0.8, and then add 10 parts of water;

[0049] Step 2, heating the carboxymethyl cellulose, acrylamide and water added to the reactor in step 1 to 50°C, stirring with a stirrer and feeding nitrogen during the heating process;

[0050] Step 3: Heat carboxymethyl cellulose, acrylamide and water in the reactor to 50°C and keep the temperature constant. After 10 minutes, gradually add 0.1mol / L initiator, and then gradually add 0.1mol / L initiator after 15 minute...

Embodiment 2

[0056] A polymer heavy metal flocculant, the structural formula of its main component is as follows:

[0057]

[0058] Wherein n is an integer of 20-3000.

[0059] Preferably in the present invention, the appearance of the polymer heavy metal flocculant is white powder, and its solution is a colorless transparent liquid.

[0060] A preparation method of polymer heavy metal flocculant, comprising the following steps:

[0061] Step 1, put a part of carboxymethyl cellulose and acrylamide into the reactor at a mass ratio of 1:0.8, and then add 10 parts of water;

[0062] Step 2, heating the carboxymethyl cellulose, acrylamide and water added to the reactor in step 1 to 60°C, stirring with a stirrer and feeding nitrogen during the heating process;

[0063] Step 3: Heat the carboxymethyl cellulose, acrylamide and water in the reactor to 60°C and keep the temperature constant. After 10 minutes, gradually add 0.1mol / L initiator, and then gradually add 0.1mol / L initiator after 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com