A kind of preparation method of polymer heavy metal flocculant

A heavy metal and flocculant technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc. and other problems, to achieve the effect of scientific charge layout, wide application range, and reduction of heavy metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

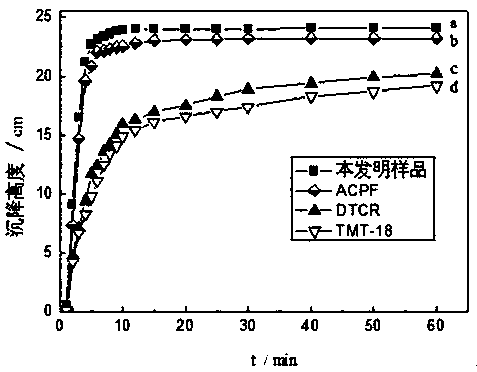

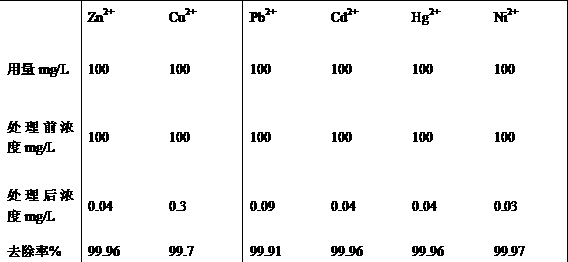

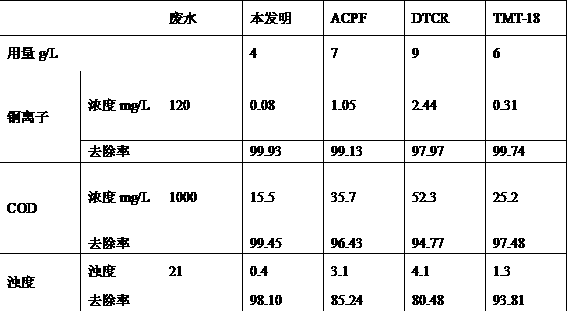

Examples

Embodiment 1

[0032] A kind of preparation method of polymer heavy metal flocculant, its preparation steps are as follows:

[0033] Step 1, put sodium carboxymethyl cellulose into the reaction kettle, then add sodium chloride solution and stir to form a constant temperature water bath reaction system;

[0034] Step 2, adding vinyl polyamine, internal initiator, and crosslinking agent into the reaction kettle, stirring and reacting at a constant temperature for 6 hours, and standing at a constant temperature for 2 hours to obtain a viscous liquid;

[0035] Step 3, open the reaction kettle, add acrylamide, carry out constant temperature heating reaction under nitrogen condition for 3 hours, at the same time add the lye of external initiator dropwise, stir for 1 hour after the reaction is completed, and let it stand for cooling;

[0036] Step 4, on the basis of step 3, slowly add carbon disulfide dropwise, stir in a constant temperature water bath for 1-3 hours, add absolute ethanol after cool...

Embodiment 2

[0050] A kind of preparation method of polymer heavy metal flocculant, its preparation steps are as follows:

[0051] Step 1, put sodium carboxymethyl cellulose into the reaction kettle, then add sodium chloride solution and stir to form a constant temperature water bath reaction system;

[0052] Step 2, adding vinyl polyamine, internal initiator, and crosslinking agent into the reaction kettle, stirring and reacting at a constant temperature for 8 hours, and standing at a constant temperature for 4 hours to obtain a viscous liquid;

[0053] Step 3, open the reaction kettle, add acrylamide, carry out constant temperature heating reaction under nitrogen condition for 5 hours, add the lye of external initiator at the same time, stir for 3 hours after the reaction is completed, and let it stand for cooling;

[0054] Step 4, on the basis of step 3, slowly add carbon disulfide dropwise, stir in a constant temperature water bath for 3 hours, add absolute ethanol after cooling, rapid...

Embodiment 3

[0068] A kind of preparation method of polymer heavy metal flocculant, its preparation steps are as follows:

[0069] Step 1, put sodium carboxymethyl cellulose into the reaction kettle, then add sodium chloride solution and stir to form a constant temperature water bath reaction system;

[0070] Step 2, adding vinyl polyamine, internal initiator, and crosslinking agent into the reaction kettle, stirring and reacting at a constant temperature for 7 hours, and standing at a constant temperature for 3 hours to obtain a viscous liquid;

[0071] Step 3, open the reaction kettle, add acrylamide, carry out constant temperature heating reaction under nitrogen condition for 4 hours, add the lye of external initiator at the same time, stir for 2 hours after the reaction is completed, and let it stand for cooling;

[0072] Step 4, on the basis of step 3, slowly add carbon disulfide dropwise, stir in a constant temperature water bath for 2 hours, add absolute ethanol after cooling, rapid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com