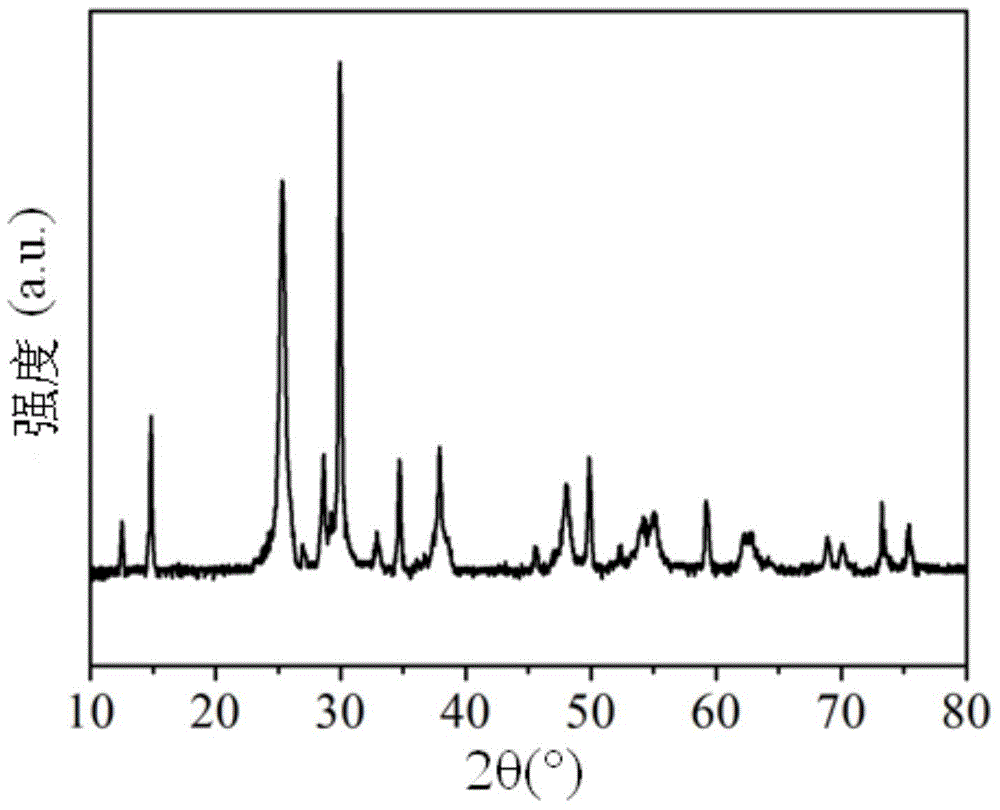

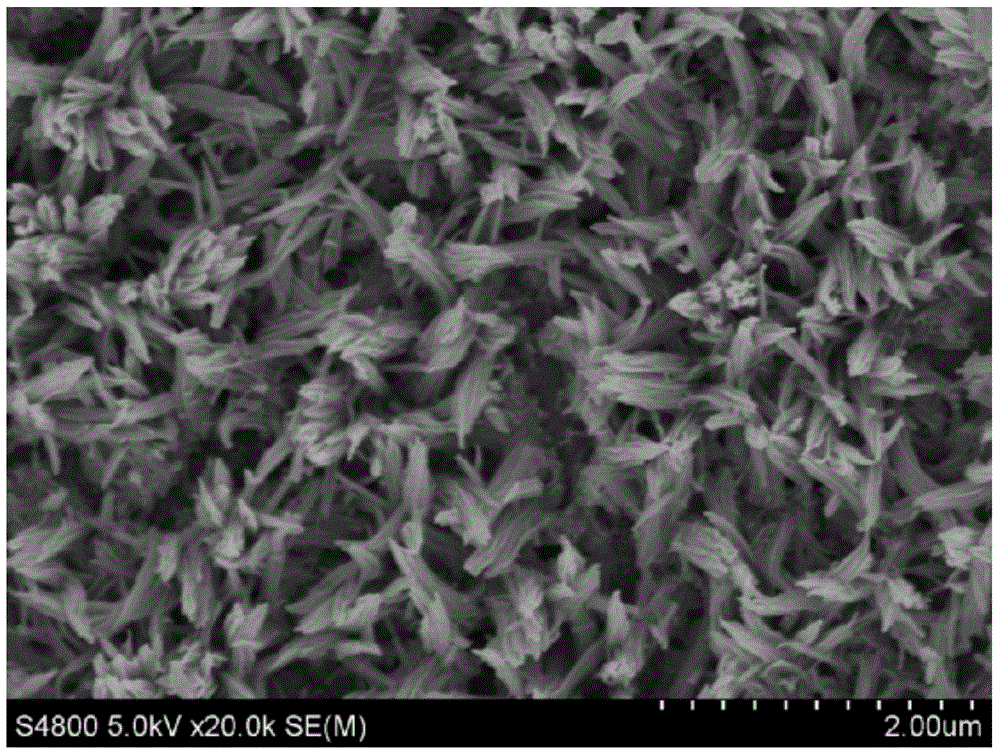

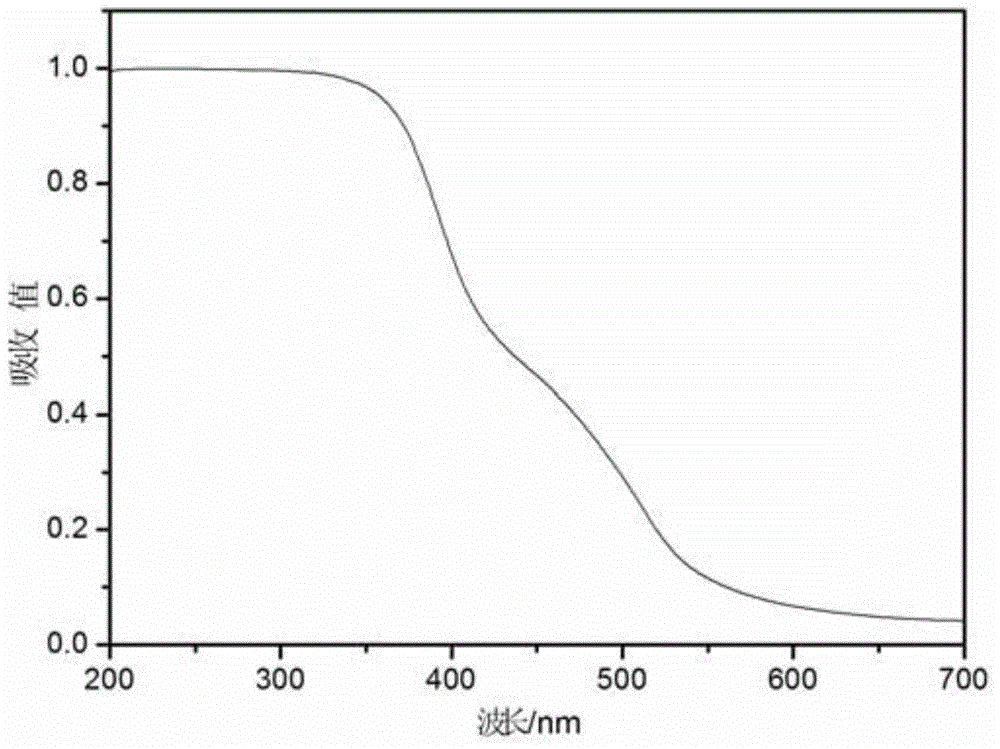

Preparation method of self-cleaning Bi2Ti2O7/TiO2 nanowire array composite film with visible-light response

A nanowire array and self-cleaning technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of resource consumption, maintaining clean surfaces, high risks, etc., and achieve low cost , easy to separate, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0024] Specific implementation mode 1: This implementation mode is a self-cleaning Bi with visible light response 2 Ti 2 o 7 / TiO 2 The preparation method of the nanowire array composite film is specifically completed according to the following steps:

[0025] 1. Preparation of a glass substrate loaded with a titanium dioxide nanowire array precursor film: Dissolve the titanium source in absolute ethanol, then add polyol, and then stir at a stirring speed of 100r / min to 300r / min for 15min to 30min to obtain Mixed solution A; move the mixed solution A into the polytetrafluoroethylene reactor, and then put the clean glass substrate into the polytetrafluoroethylene reactor at an angle of 60° to the axis of the polytetrafluoroethylene reactor , then put the sealed polytetrafluoroethylene reactor into a drying oven with a temperature of 180°C to 200°C for heating for 10h to 24h, then cool the sealed polytetrafluoroethylene reactor to room temperature naturally, and place the gla...

specific Embodiment approach 2

[0037] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the titanium source described in step 1 is isopropyl phthalate or tetrabutyl titanate. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0038] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the polyhydric alcohol described in step 1 is glycerol. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com