Tile bonding glue prepared from red mud

An adhesive and red mud technology, applied in the field of dry-mixed mortar tile adhesive and tile adhesive, can solve the problems of slow progress and low utilization of red mud, and achieve low cost, good freeze-thaw resistance, Good anti-slump effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

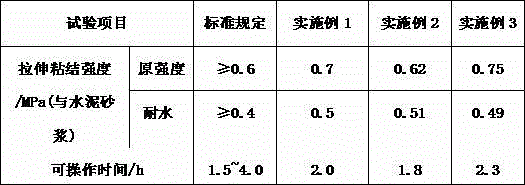

Examples

Embodiment 1

[0021] Component Recipe (kg) dry powdered water glass 10 red mud 35 Slag 325 mesh 35 Metakaolin 5 fly ash 3 Gypsum powder 5 Silica fume 1 latex powder 1 Aquasorb 0.5 retarder 1 aggregate 120

Embodiment 2

[0023] Component Recipe (kg) dry powdered water glass 15 red mud 30 Slag 600 mesh 40 Metakaolin 10 fly ash 5 Gypsum powder 1 Silica fume 3 latex powder 2 Aquasorb 0.7 retarder 2 aggregate 180

Embodiment 3

[0025] Component Recipe (kg) dry powdered water glass 12 red mud 40 Slag 325 mesh 30 Metakaolin 8 fly ash 2 Gypsum powder 1 Silica fume 2 latex powder 3 Aquasorb 0.2 retarder 1.8 aggregate 150

[0026] Adopt the present invention of above-mentioned raw material, all be prepared by following method:

[0027] (1) Drying, crushing and sieving the red mud to obtain dry powdered red mud with a fineness greater than 400 mesh and a water content not higher than 5%;

[0028] (2) Weigh various raw materials according to the proportion;

[0029] (3) Mix all kinds of raw materials in a gravity-free mixer evenly, regardless of the order of feeding;

[0030] (4) Pack the well-mixed dry powder mortar in a sealed plastic woven bag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com