Method for preparing continuous fiber cloth reinforced silica ceramic-based composite material

A continuous fiber and silica technology, which is applied in the preparation of composite materials and the preparation of continuous fiber cloth reinforced silica ceramic matrix composite materials, can solve the problems of many operators and long weaving time, so as to reduce costs and improve Excellent mechanical properties and thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment includes the following steps:

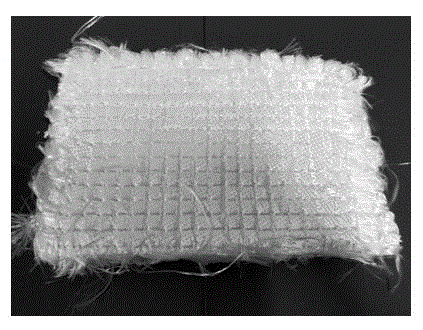

[0032] (1) First, take 5 layers of satin quartz fiber cloth as a unit, lay them together, and then sew the 5 layers of fiber cloth together with bundles of fibers; the suture line forms a sinusoidal line trend in the 5 layers of cloth;

[0033] (2) Lay another unit of fiber cloth on the fiber cloth sewn by the first unit, and then repeat the sewing process in step (1). stitched together;

[0034] (3) Repeat step (2) for a total of 10 units to obtain a laminated stitched fiber cloth prefabricated part;

[0035] Perform normal puncture on the laminated stitched fiber cloth preform; the method of normal puncture is: use the stitching yarn to puncture the fiber cloth laminated fabric prepared according to the previous steps (1)~(3) to obtain a laminated Stitched and punctured fiber cloth prefabricated parts; laminated stitched and punctured fiber cloth prefabricated parts or fiber volume fraction in laminated stitched and pu...

Embodiment 2

[0047] This embodiment includes the following steps:

[0048] (1) First, take 5 layers of twill quartz fiber cloth as a unit, lay them together, and then sew the 5 layers of fiber cloth together with bundles of fibers; the suture line forms a sinusoidal line trend in the 5 layers of cloth;

[0049](2) Lay another unit of fiber cloth on the fiber cloth sewn by the first unit, and then repeat the sewing process in step (1). stitched together;

[0050] (3) Then design the thickness according to the material or component prefabrication, and repeat step (2) to obtain a laminated stitched fiber cloth prefabrication (5 layers of cloth per unit, 10 units, a total of 50 layers of cloth, and the stitching stitch density is 10× 10mm, the normal puncture density is 5×5mm);

[0051] Perform normal puncture on the laminated stitched fiber cloth preform; the method of normal puncture is: use the stitching yarn to puncture the fiber cloth laminated fabric prepared according to the previous ...

Embodiment 3

[0062] This embodiment includes the following steps:

[0063] (1) First, take 5 layers of satin quartz fiber cloth as a unit, lay them together, and then sew the 5 layers of fiber cloth together with bundles of fibers; the suture line forms a sinusoidal line trend in the 5 layers of cloth;

[0064] (2) Lay another unit of fiber cloth on the fiber cloth sewn by the first unit, and then repeat the sewing process in step (1). stitched together;

[0065] (3) Repeat step (2) for a total of 10 units to obtain a laminated stitched fiber cloth prefabricated part;

[0066] Perform normal puncture on the laminated stitched fiber cloth preform; the method of normal puncture is: use the stitching yarn to puncture the fiber cloth laminated fabric prepared according to the previous steps (1)~(3) to obtain a laminated Stitched and punctured fiber cloth prefabricated parts; laminated stitched and punctured fiber cloth prefabricated parts or fiber volume fraction in laminated stitched and pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com