Silicon-rich biochar organic fertilizer

A technology of biochar and organic fertilizer, which is applied to the treatment of bio-organic parts, organic fertilizers, and the preparation of organic fertilizers. Absorption and utilization of crops, continuous effect of fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

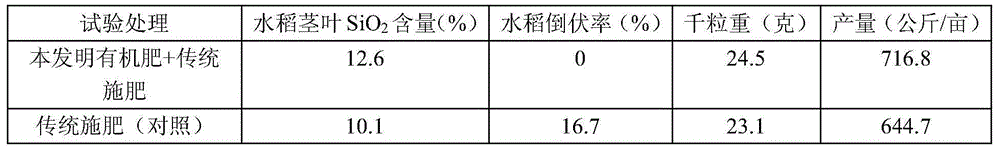

Examples

Embodiment 1

[0028] A silicon-rich biochar organic fertilizer, which is prepared by the following method:

[0029] (1) One-time fermentation: mix 80 parts by weight of rice hulls, 20 parts by weight of rice bran and 0.2 parts by weight of Bacillus subtilis liquid (commercially available, with a viable number of more than 90 million cells / ml) to obtain a first-time mixture, add water to adjust once The moisture content of the mixed material is 60%. Build a pile and ferment for 5 days. The pile is placed indoors. The environment temperature of the pile should be above 10℃. During this period, the pile should be turned up and down when the temperature in the pile rises above 70℃. , To supplement oxygen and cool down.

[0030] (2) Secondary fermentation: When the temperature of the primary mixture pile after the primary fermentation drops below 40℃, add rice husk biochar and EM bacteria liquid (commercially available) to the primary mixture pile, and the amount of rice husk biochar It is 30% of th...

Embodiment 2

[0035] A silicon-rich biochar organic fertilizer, which is prepared by the following method:

[0036] (1) One-time fermentation: mix 90 parts by weight of rice hulls, 10 parts by weight of rice bran and 0.4 parts by weight of Bacillus subtilis liquid (commercially available, with a viable number of more than 90 million cells / ml) to obtain a mixed material once, add water to adjust once The water content of the mixed material is 70%, and the one-time mixed material is piled up and fermented for 7 days, and stacked indoors. The ambient temperature of the stacking place should be above 10℃. During this period, the pile should be turned up and down when the temperature in the pile rises above 70℃. , To supplement oxygen and cool down.

[0037] (2) Secondary fermentation: When the temperature of the primary mixture pile after the primary fermentation drops below 40℃, add rice husk biochar and EM bacteria liquid (commercially available) to the primary mixture pile, and the amount of rice...

Embodiment 3

[0042] A silicon-rich biochar organic fertilizer, which is prepared by the following method:

[0043] (1) One-time fermentation: 85 parts by weight of rice hulls, 15 parts by weight of rice bran and 0.3 parts by weight of Bacillus subtilis liquid (commercially available, number of viable bacteria greater than 90 million / ml) are mixed and stirred to obtain a mixture of materials, and water is added to adjust once The moisture content of the mixed material is 65%. Build a pile of mixed materials for fermentation for 6 days, and stack them indoors. The environment temperature of the pile should be above 10℃. During the period, when the temperature in the pile rises above 70℃, the pile should be turned up and down. , To supplement oxygen and cool down.

[0044] (2) Secondary fermentation: When the temperature of the primary mixture pile after the primary fermentation drops below 40℃, add rice husk biochar and EM bacteria liquid (commercially available) to the primary mixture pile, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com