Preparation method of benzoyl chloride

A technology of benzoyl chloride and benzoic acid, which is applied in the field of preparation of benzoyl chloride, can solve the problems of high catalyst or corrosive toxicity, unstable nature and low catalytic efficiency, etc., so as to speed up the chlorination reaction rate and improve the utilization of light sources. efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add 100g of toluene and 0.1g of inhibitor (the mass ratio of benzoquinone, DNBP, and DDBSA to 1:2:4) into the reaction bottle, first raise the temperature to 85°C, and start to pass the reaction bottle under the irradiation of LED light (wavelength: 380nm-450nm). Chlorine, the temperature rises slowly with the reaction, and the final temperature is controlled at 130°C. The total reaction time is 6 hours. The chlorine gas flow rate is 50g / h for 0-3 hours. As the degree of chlorination continues to increase, the chlorine gas flow rate is 30g / h for 4-6 hours. 210 g of crude benzyl trichloride was obtained with a chromatographic content of 97.2% and a yield of 96.2%.

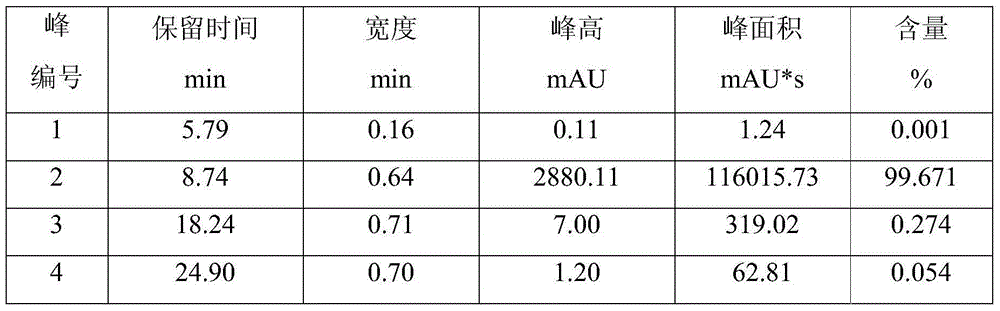

[0036] Weigh 50g of benzoic acid and 0.25g of zinc chloride, heat up and melt the benzoic acid, add 81.2g of the crude benzyl trichloride obtained in the above reaction dropwise at 130±5°C, and keep the temperature for 0.5h after dropping over 0.5h. No tail gas is generated. , at 20mmHg underpressure distilla...

Embodiment 2

[0040] Add 200g of toluene and 1g of inhibitor (the mass ratio of benzoquinone, DNBP, and DDBSA is 1:2.1:4.2) to the reaction bottle, and pass chlorine gas at 100±10°C under the irradiation of LED light (wavelength: 380nm-450nm). Slowly heat up with the reaction, total reaction 8h, 0~3h chlorine gas flow rate is 85g / h, 4h chlorine gas flow rate is controlled at 70g / h, 5~6h chlorine gas flow rate is 55g / h, 7~8h chlorine gas flow rate is 45g / h. At the end of the reaction, 424 g of the crude product of benzyl trichloride was obtained, the chromatographic content was 97.1%, and the yield was 97.5%.

[0041] Weigh 100g of benzoic acid, 0.1g of ferric trichloride, heat up and melt the benzoic acid, add 168g of the crude benzyl trichloride obtained in the above reaction dropwise at a temperature of 130±5°C, and keep the temperature for 0.5h after dropping for 1 hour. Distilled under reduced pressure at 15 mmHg to obtain 222 g of fine benzoyl chloride with a chromatographic content of...

Embodiment 3

[0043] Add 150g of toluene and 0.3g of inhibitors (the mass ratio of benzoquinone, DNBP, and DDBSA is 0.8:2.2:4) to the reaction flask, and slowly heat up at 110±10°C under the irradiation of LED light (wavelength: 380nm-450nm). A total of 7 hours of reaction, 0 ~ 3h chlorine gas flow rate of 70g / h, 4 ~ 5h chlorine gas flow rate of 45g / h, 6 ~ 7h chlorine gas flow rate of 35g / h. At the end of the reaction, 317 g of crude product benzyl trichloride was obtained, the chromatographic content was 97.5%, and the yield was 97.4%.

[0044] Weigh 80g of benzoic acid and 0.3g of aluminum trichloride, heat up and melt the benzoic acid, add dropwise 126g of the crude benzyl trichloride obtained in the above reaction at a temperature of 130±5°C, and keep the temperature for 0.5h after dropping over 0.5h. No tail gas is generated. , Distilled under reduced pressure at 30mmHg to obtain 179g of benzoyl chloride refined product, with a chromatographic content of 99.7% and a yield of 97.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com