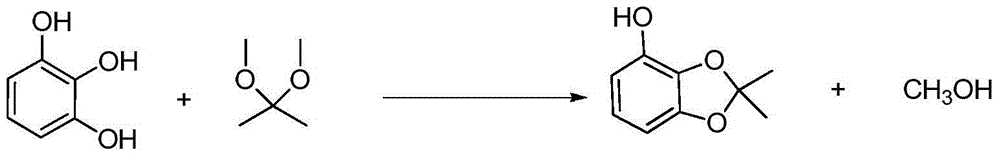

Preparation method of 4-hydroxy-2,2-dimethyl-1,3-benzodioxole

A technology of dimethyl and dimethoxypropane, which is applied in the field of preparation of 4-hydroxy-2,2-dimethyl-1,3-benzodioxin, can solve problems such as unfavorable industrialized production, and achieves The effect of low material ratio, improved selectivity and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: Φ 1.5cm, height 120cm and the rectifying tower with condenser are housed on the reactor of 1000ml band agitation, the rectifying tower bottom fills 10cm methanesulfonic acid dry resin catalyst, adds 100.8g in the reactor (0.8mol) pyrogallic acid and 580ml toluene, after stirring and dissolving, the temperature is raised to 110°C, and the mixed solution of 124.8g (1.2mol) 2,2-dimethoxypropane (DMP) and 60ml toluene is started to be added dropwise. Dropwise reaction, control the DMP and toluene drop rate in 6 hours to complete the addition. The by-product methoxypropene (MP) and by-product methanol produced by the reaction pass through the rectification tower, and react under the action of methanesulfonic acid dry resin at the bottom of the rectification tower to generate raw material 2,2-dimethoxypropane (DMP ), the newly generated DMP returns to the reactor to participate in the reaction of preparing 4-hydroxyl-2,2-dimethyl-1,3-benzodioxol again. The exce...

Embodiment 2

[0016] Add 100.8g (0.8mol) pyrogallic acid and 580ml xylene in the 1000ml band stirred reaction kettle of the rectifying tower that Φ 1.5cm, high 120cm, bottom filling 10cm methanesulfonic acid dry resin catalyst are equipped, Raise the temperature to 110°C, start to drop the mixed solution of 124.8g (1.2mol) DMP and 60ml xylene, control the rate of addition to finish adding in 6 hours, the by-product methoxypropene (MP) and by-product methanol produced by the reaction After passing through the rectification tower, the raw material 2,2-dimethoxypropane (DMP) is regenerated under the action of methanesulfonic acid dry resin, the catalyst at the bottom of the rectification tower, and the newly generated DMP returns to the reactor to participate in the preparation of 4-hydroxy -2,2-Dimethyl-1,3-benzodioxol reaction. The excess by-product methanol is removed from the tower top condenser, and the product 4-hydroxy-2,2-dimethyl-1,3-benzodioxol reaction liquid is obtained in the towe...

Embodiment 3

[0018] Equipped with mechanical stirring and tower diameter 1.5cm, tower height 120cm, in the 1000ml reactor that equal diameter 10cm high methanesulfonic acid catalyst is housed at the bottom of the tower, add 100.8g (0.8mol) pyrogallic acid and 580ml toluene, heat up To 125 ℃, start to drop the mixed solution of the DMP of 124.8g (1.2mol) and 60ml xylene, control the rate of addition and add in 6 hours, the by-product methoxypropene (MP) that reaction produces and by-product methyl alcohol pass through The rectification tower, under the action of methanesulfonic acid dry resin, the catalyst at the bottom of the rectification tower, reacts and regenerates the raw material 2,2-dimethoxypropane (DMP), and the newly generated DMP returns to the reactor to participate in the preparation of 4-hydroxy- 2,2-Dimethyl-1,3-benzodioxol reaction. The excess by-product methanol is removed from the tower top condenser, and the product 4-hydroxy-2,2-dimethyl-1,3-benzodioxol reaction liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com