Calcium silicate fiber special for stone paper and preparation method thereof

A technology of stone paper and calcium silicate, applied in the field of stone paper, can solve the problems such as hindering the popularization and application process of stone paper, difficulty in exerting fiber network support, difficulty in network structure, etc., and achieves good hand feeling, reduced density and compatibility good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

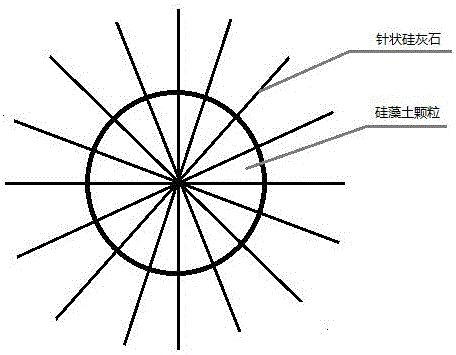

[0031](1) Suspend and debundle 60 parts by weight of wollastonite with a fibrous crystal structure in a flat jet mill, control the classification speed at 2000 rpm, and obtain acicular wollastonite powder through supersonic debundling and classification by airflow;

[0032] (2) Add the acicular wollastonite powder obtained in step (1) into 40% dilute sulfuric acid, stir and acidify for 2-3 hours, then filter, soak in excess styrene solution for 24 hours, and make the acicular wollastonite single The bundle fibers are completely soaked in styrene solution, and the excess styrene is filtered through a centrifuge to obtain modified wollastonite;

[0033] (3) Add 40 parts by weight of diatomite to 30% dilute sulfuric acid, stir and acidify for 2-3 hours, then filter, soak in excess styrene solution for 24 hours, so that the diatomite is completely soaked in styrene solution, and centrifuge Excess styrene is filtered by machine to obtain modified diatomite;

[0034] (4) Send the m...

Embodiment 2

[0037] (1) Suspend and debundle 80 parts by weight of wollastonite with a fibrous crystal structure in a vortex jet mill, control the classification speed at 2000 rpm, and obtain acicular wollastonite powder through supersonic debundling and classification by airflow;

[0038] (2) Add the acicular wollastonite micropowder obtained in step (1) into 50% dilute sulfuric acid, stir and acidify for 2-3 hours, then filter, soak in excess styrene solution for 24 hours, and make the acicular wollastonite single The bundle fibers are completely soaked in styrene solution, and the excess styrene is filtered through a centrifuge to obtain modified wollastonite;

[0039] (3) Add 20 parts by weight of diatomite to dilute sulfuric acid with a concentration of 50% to stir and acidify for 2-3 hours, then filter, soak in excess styrene solution for 24 hours, so that the diatomite is completely soaked in styrene solution, and centrifuge Excess styrene is filtered by machine to obtain modified d...

Embodiment 3

[0043] (1) Suspend and debundle 70 parts by weight of wollastonite with a fiber crystal structure in a vortex jet mill, control the classification speed at 2300 rpm, and obtain acicular wollastonite powder through supersonic debundling and classification by airflow;

[0044] (2) Add the acicular wollastonite powder obtained in step (1) into 30% dilute sulfuric acid, stir and acidify for 2-3 hours, then filter, soak in excess styrene solution for 24 hours, and make the acicular wollastonite single The bundle fibers are completely soaked in styrene solution, and the excess styrene is filtered through a centrifuge to obtain modified wollastonite;

[0045] (3) Add 30 parts by weight of diatomite to dilute sulfuric acid with a concentration of 50% and stir to acidify for 2-3 hours, then filter, soak in excess styrene solution for 24 hours, so that the diatomite is completely soaked in styrene solution, and centrifuge Excess styrene is filtered by machine to obtain modified diatomit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com