Environment-friendly nail-free glue and preparation method thereof

An environmentally friendly, nail-free adhesive technology, used in adhesives, adhesive types, polyether adhesives, etc., can solve problems such as low toxicity, toxic and harmful, health and environmental hazards, and achieve easy dehydration and good adhesion. Connectivity, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

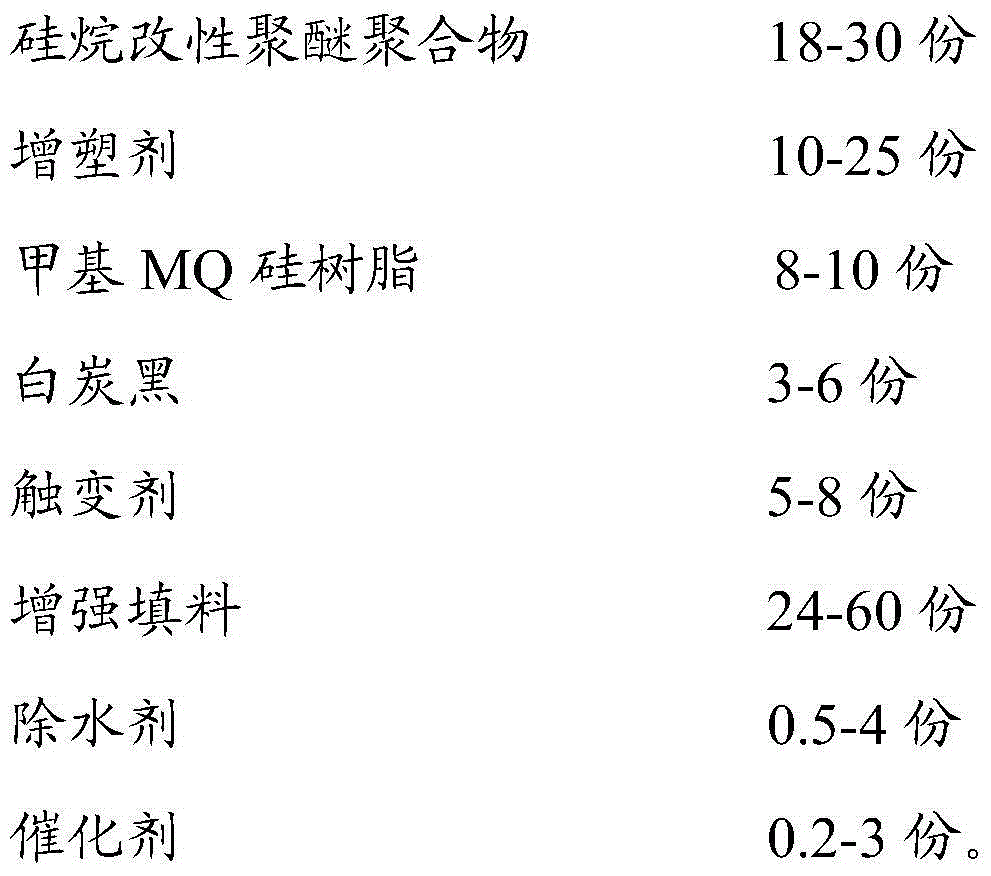

[0036] In this embodiment, an environment-friendly nail-free glue comprises the following raw materials in parts by weight:

[0037] in,

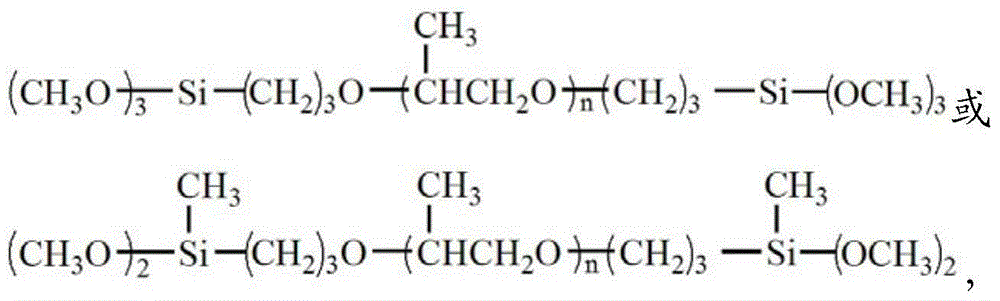

[0038] Described silane-modified polyether polymer is:

[0039] The viscosity is 7Pa.s;

[0040] The structure of the methyl MQ silicone resin is (Me 3 SiO 0.5 ) a (SiO 2 ) b , where a / b=0.5.

[0041] The preparation method of the above-mentioned environment-friendly nail-free glue comprises the following steps:

[0042] Add 10 parts of silane-modified polyether polymer, 15 parts of dioctyl phthalate, 10 parts of methyl MQ silicone resin, 5 parts of white carbon black, 2 parts of polyamide wax, and 39 parts of heavy calcium carbonate into the kneader Heating and vacuum kneading for 1 hour, the heating temperature is 130°C, the vacuum degree is -0.09MPa, and the discharged material is used as the base material.

[0043] After the base material is cooled to a temperature lower than 50°C, transfer it to a planetary mixer, add the ...

Embodiment 2

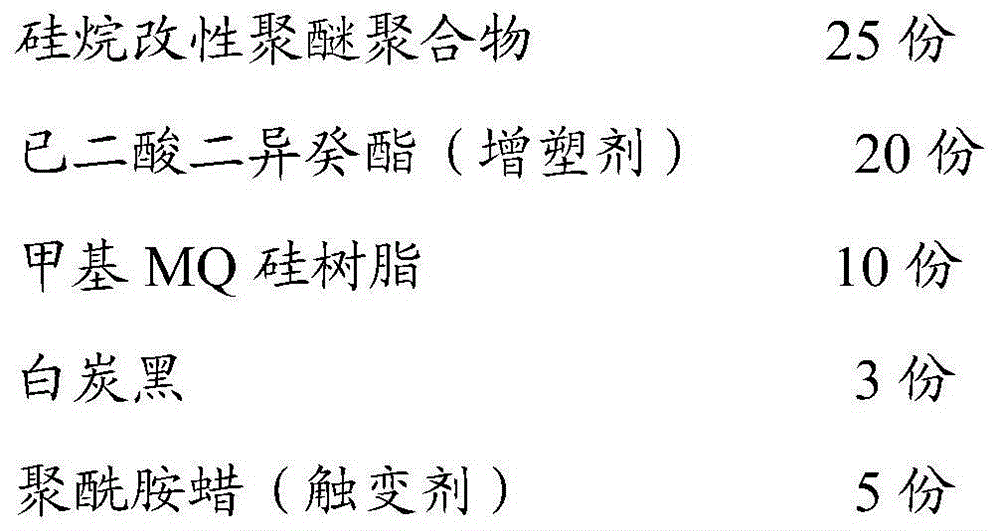

[0045] In this embodiment, an environment-friendly nail-free glue comprises the following raw materials in parts by weight:

[0046]

[0047] in,

[0048] Described silane-modified polyether polymer is:

[0049] 10 parts of polymer with viscosity of 6pa.s, 15 parts of polymer with viscosity of 13pa.s;

[0050] The structure of the methyl MQ silicone resin is (Me 3 SiO 0.5 ) a (SiO 2 ) b , where a / b=1.0.

[0051] The preparation method of the above-mentioned environment-friendly nail-free glue comprises the following steps:

[0052] Add 25 parts of silane-modified polyether polymer, 10 parts of diisodecyl adipate, 10 parts of methyl MQ silicone resin, 3 parts of white carbon black, 5 parts of polyamide wax, and 31 parts of light calcium carbonate into the kneader Heating and vacuum kneading for 3 hours, the heating temperature is 110°C, the vacuum degree is -0.1MPa, and the discharged material is used as the base material.

[0053] After the base material is coo...

Embodiment 3

[0055] In this embodiment, an environment-friendly nail-free glue comprises the following raw materials in parts by weight:

[0056] in,

[0057] Described silane-modified polyether polymer is:

[0058] 45 parts of polymers whose viscosity is 8pa.s, and 5 parts of polymers whose viscosity is 82pa.s;

[0059] The structure of the methyl MQ silicone resin is (Me 3 SiO 0.5 ) a (SiO 2 ) b , where a / b=0.8.

[0060] The preparation method of the above-mentioned environment-friendly nail-free glue comprises the following steps:

[0061] Add 50 parts of silane-modified polyether polymer, 2 parts of PPG1000, 5 parts of methyl MQ silicone resin, 10 parts of white carbon black, and 24 parts of light calcium carbonate into the kneader, heat and knead under vacuum for 2 hours, and the heating temperature is 120°C , the vacuum degree is -0.095MPa, and the output is used as the base material.

[0062] After the base material is cooled to a temperature below 50°C, transfer it to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com