Vanadium-containing hypereutectic high-chromium cast iron and manufacturing method thereof

A technology of high-chromium cast iron and a manufacturing method, which is applied in the field of high-chromium cast iron, can solve the problems of narrow applicability, complicated process and high cost, and achieves the effects of stable product quality, broad market prospect, and simple and economical manufacturing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

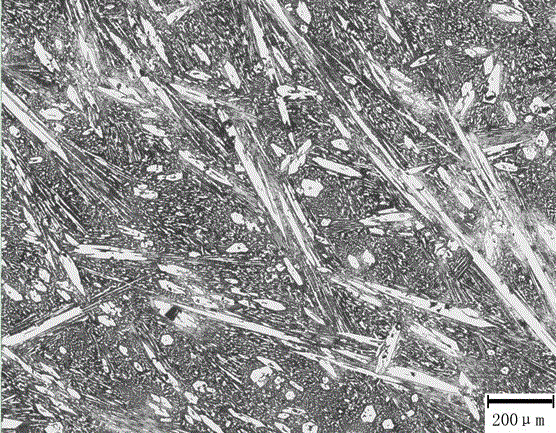

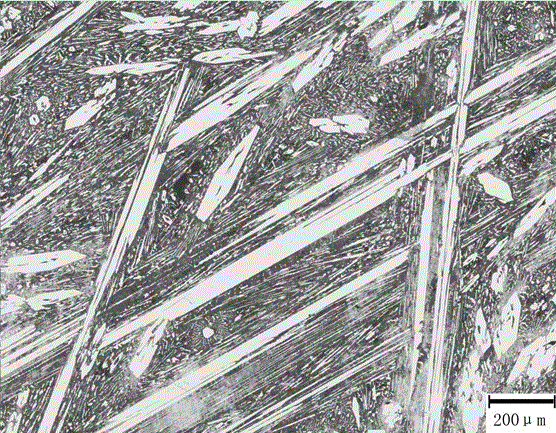

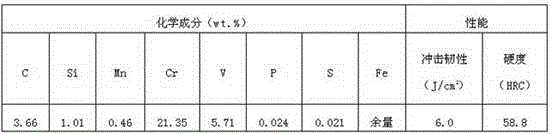

Image

Examples

Embodiment 1

[0037] A method for manufacturing vanadium-containing hypereutectic high-chromium cast iron, which has the following steps:

[0038] (1) Add 205kg of high-carbon ferrochrome (FeC55C600II), 110kg of pig iron for steelmaking (L04), and 127kg of scrap steel into a 500kg medium-frequency induction furnace, and heat them to melt them into molten iron;

[0039] (2) Raise the temperature of the molten iron to 1500-1600°C, and add 0.5kg of aluminum powder to the molten iron;

[0040] (3) Preheat ferrovanadium (FeV50-B) with a weight of 58kg to 470-580°C and add it into the molten iron, melt all the ferrovanadium at a temperature of 1400-1450°C and evenly disperse it in the molten iron, and then put The temperature of molten iron is raised to 1500-1600°C and released;

[0041](4) Put 2.0kg of ferro-titanium particles with a particle size of less than 10mm in the bottom of the bag, and use the flushing method to inoculate the molten iron; after the inoculation is completed and the slag...

Embodiment 2

[0046] A method for manufacturing vanadium-containing hypereutectic high-chromium cast iron, which has the following steps:

[0047] (1) Add 155kg of high-carbon ferrochromium (FeC55C1000II), 90kg of pig iron for steelmaking (L04), 179kg of scrap steel and 3kg of high-carbon ferromanganese (FeMn78C8.0) into a 500kg intermediate frequency induction furnace, and heat them to melt them into molten iron;

[0048] (2) Raise the temperature of the molten iron to 1500-1600°C, and add 0.5kg of aluminum powder to the molten iron;

[0049] (3) Preheat ferrovanadium (FeV50-B) with a weight of 73kg to 470-580°C and add it into the molten iron, melt all the ferrovanadium at a temperature of 1400-1450°C and disperse it evenly in the molten iron, and then put The temperature of molten iron is raised to 1500-1600°C and released;

[0050] (4) Put 2.0kg of ferro-titanium particles with a particle size of less than 10mm in the bottom of the bag, and use the flushing method to inoculate the molt...

Embodiment 3

[0055] A method for manufacturing vanadium-containing hypereutectic high-chromium cast iron, which has the following steps:

[0056] (1) Add 200kg of high-carbon ferrochromium (FeC55C600II), 188kg of pig iron for steelmaking (L04), 50kg of scrap steel and 2kg of high-carbon ferromanganese (FeMn78C8.0) into a 500kg intermediate frequency induction furnace, and heat them to melt them into molten iron;

[0057] (2) Raise the temperature of the molten iron to 1500-1600°C, and add 0.5kg of aluminum powder to the molten iron;

[0058] (3) Preheat ferrovanadium (FeV50-B) with a weight of 60kg to 470-580°C and add it into the molten iron, melt all the ferrovanadium at 1400-1450°C and disperse it evenly in the molten iron, and then put The temperature of molten iron is raised to 1500-1600°C and released;

[0059] (4) Put 2.0kg of ferro-titanium particles with a particle size of less than 10mm in the bottom of the bag, and use the flushing method to inoculate the molten iron; after the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com