Preparation method for forming second-level porous active surface structure on titanium material surface through mixed alkali

A technology of active surface and mixed alkali, which is applied in the field of preparation of secondary porous active surface structure, can solve the problems of low biological activity of titanium and titanium alloy, low bonding strength of bone tissue, etc., to promote integration, promote nucleation and growth, The effect of accelerating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

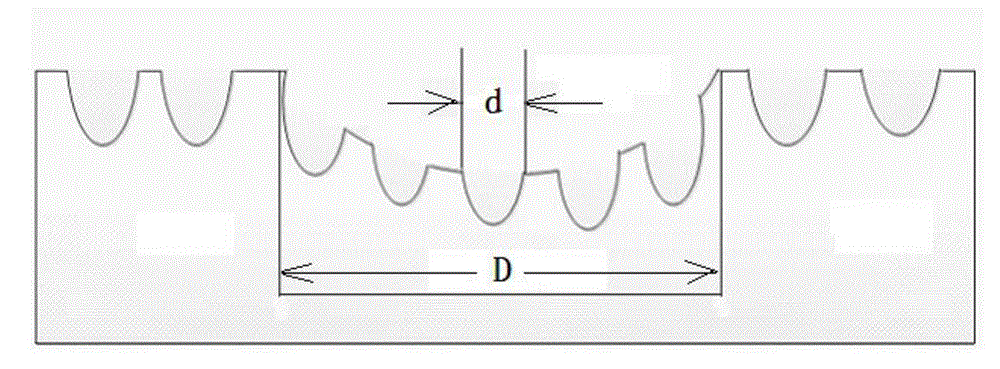

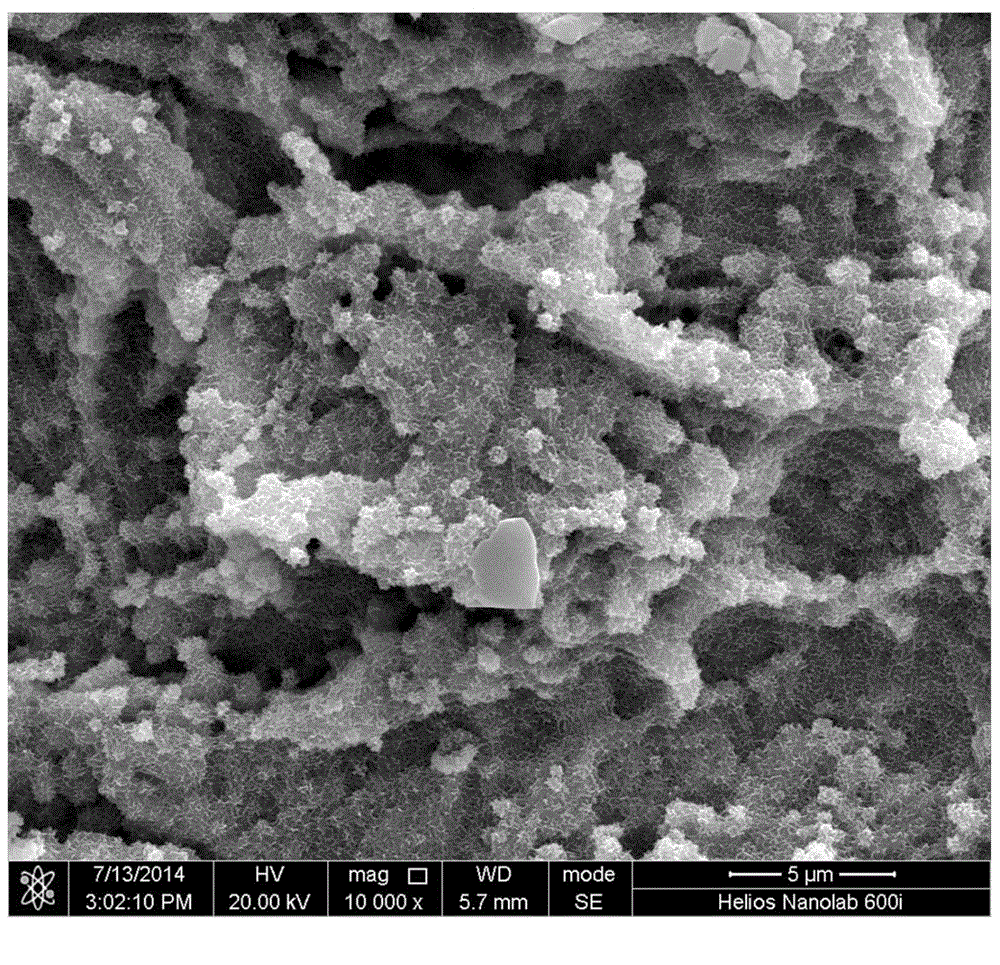

[0016] Specific embodiment one: In this embodiment, a preparation method for forming a secondary porous active surface structure on the surface of a titanium material by using a mixed alkali is carried out according to the following steps:

[0017] 1. Grinding treatment: The titanium material is polished step by step with 200#, 400#, 600# and 1000# metallographic sandpaper until the surface has a metallic luster, and then at room temperature, first use acetone ultrasonic cleaning for 15min~30min, and then use alcohol Ultrasonic cleaning for 15 minutes to 30 minutes, and finally drying to obtain polished titanium materials;

[0018] 2. Sand blasting treatment: Sand blast the polished titanium material with alumina particles, and then at room temperature, first use acetone ultrasonic cleaning for 15 minutes to 30 minutes, then use alcohol ultrasonic cleaning for 15 minutes to 30 minutes, and finally dry to obtain Titanium material after sandblasting;

[0019] 3. Acid etching tr...

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment is different from Embodiment 1 in that: the titanium material in step 1 is titanium or titanium alloy. Others are the same as the first embodiment.

specific Embodiment approach 3

[0024] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the particle size of the alumina particles in the sand blasting treatment in step 2 is 300 μm, the treatment pressure is 0.3 KPa, and the sand blasting time is 30 s. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com